Archive

The importance of definitions

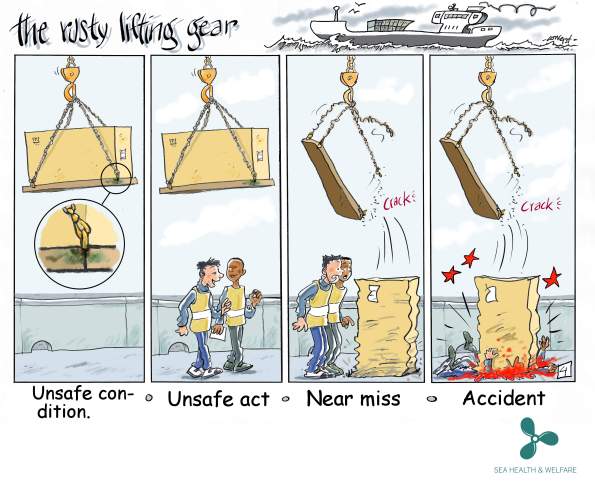

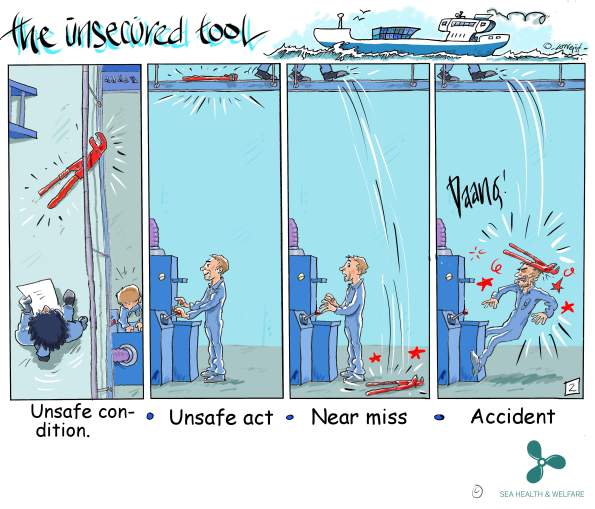

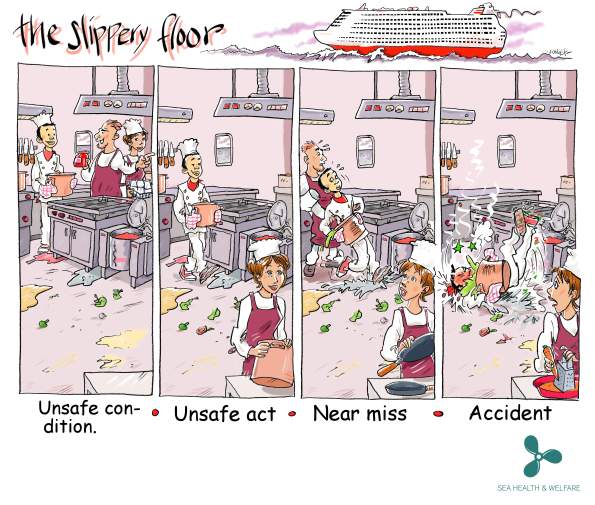

Following a few recent blogs regarding H&S incidents I thought I’d share these little cartoons we found depicting the different terminology for various incident types.

The first image seems particularly relevant for both Mark’s and Al’s recent experience with lifting equipment. From reading the blogs it sounds to me like Al’s site experienced and unsafe act when a worker was seen under an unsupported load. Mark experienced an unsafe condition (the poor slinging technique) which led to a near miss (the thing actually fell but no one was hurt).

While of course all of these incident types should be properly addressed, and all have degrees of severity within them, the terminology used can be quite important.

Take, for example, our ever-troublesome scaffolders who failed to properly enforce an exclusion zone on a public-access pavement beneath their work area. They were spotted and the situation was corrected but was this a near miss? Nothing was dropped onto the pavement and no one was injured but the potential was there. This was reported as an unsafe condition (working overhead without edge protection). Had it been labelled a near miss (with the potential to impact the public) we would have had a world of problems.

This may sound like opportunistic word play but it is an important delineation. From a safety point of view it was a very serious occurrence, and was treated as such by all involved, but contractually the wording is vital, similar I suppose to John Holland’s 1P rating in addition to the strict H&S term. The irony of the situation is they were up there erecting a scaffold fan to protect pedestrians from falling objects!

A great deal of fallout resulted of course (revisiting method statements, tool box talks, safety briefings, etc) but the point of this blog was the importance of definitions in contractual communication, and not just in H&S.

Precast pile de-heading

Hi all! I just thought I’d put up a quick post about a new technology/process I have been involved with this week.

Having almost completed the first stage of precast pile installation on my site, we are ready to start de-heading piles in preparation for pile cap construction.

Pile de-heading is recognised as a risky activity within the construction industry. Eventually, approximately 4500 precast concrete piles (13,500 individual pile segments when considering spliced piles) will be installed across the east zone of the West Gate Tunnel Project. Given the inherent risk of the deheading activity, a concerted effort has been undertaken to investigate the safest ways to undertake each stage of the process.

A lot of thought and consideration has gone into the different methods available to remove or reduce the people and plant interface, a High Risk Construction Work Activity under Victoria Worksafe (Vic State version of HSE), which are activities involving people working in close vicinity to items of plant.

De-heading or pile-trimming refers to the practice of cutting piles to a pre-determined level after they’ve been driven into the ground to the required depth or capacity, which is around 30 metres generally across the East Zone and 12m-14m across the scope of works conducted thus far on my area of responsibility.

Traditionally a number of methods have been used to perform the de-heading, including workers using hand-held ‘demo’ saws in combination with plant to support and remove cut sections. Typically, this activity involves a crane holding the pile, while workers saw cut the concrete and corner longitudinal reinforcement This involves a lot of people/plant interface and other safety risks such as: falling concrete segments, potential silica dust inhalation, injuries associated with repetitive tasks (such as ‘White Finger’ vibration injuries) and exposure to loud noises.

After investigations into safer options with the piling subcontractor ‘Keller’, it was decided a much safer method for these works was to use an excavator with a de-heading attachment. How does it work?

How does it work?

In simple terms, after the de-heading attachment is connected to an excavator arm, it connects to a pile and its blades cut through the reinforcing steel at each corner. Another excavator then moves in, grabs the pile and snaps it at the cut-off point and then carries the excess length of pile directly to the waste skip for removal. This technology is not entirely new and has been used before in Australia, but rarely, as it suits projects with a large-scale piling requirement, such as ours due to the increased costs.

The main benefits of using this pile-trimmer method include:

1. Safety: as this process is undertaken via an excavator, it completely removes the people/plant interface.

2. Environmental improvements: it’s quieter than other options, such as jackhammers, while dust dispersion is mitigated as the device ‘self-doses’ water during cutting.

3. Increased productivity: this method is quicker than other de-heading methods, meaning increased cost of plant/technology can be saved against traditional methods through saving in time and project schedule.

4. A better result: the end of the cut-off pile is ‘cleaner’ than it would be using other methods.

What’s next after the pile de-heading?

unfortunately, the plant trimming method cannot be used down to the final cut-off level of the pile. After the piles have been trimmed to the correct height (300mm above the surface), the next step is known as breaking-back the pile. It involves digging around the piles to the cut-off level, then chipping away the concrete to exposing the reo bars.

This is another process that will be performed mostly by excavator, with only minimal use of a jackhammer at the final stage, to expose the reinforcing steel. Again, reducing the risks to workers on site.

This method of pile de-heading is a big step forward for safety across the industry and will likely see increased use in the future, especially with Tier 1 Contractors.