Point-cloud Data Capture for Tolerance Analysis of ‘As-built’ Structures within the HPC Nuclear Programme

The Main Civil Works (MCW) contract in place for Hinkley Point C (HPC) has seen a vast amount of concrete being poured, using vast amounts of rebar. Most rebar used on site was due to be at least 43mm in diameter but in response to lessons learnt in the Fukushima nuclear accident, the design has been strengthened in many places and now contains ‘double tied’ rebar – at least 86mm across. HPC’s civil structure concrete will also contain thousands of embedded items such as plates (90,000 of!), mounting bolts and ‘Halfen’ rails on which the many E&M systems, structures and components (SSCs) will be placed.

Due to the rebar situation, the MCWs are working off around +/- 80mm tolerances for their embedded items. The E&M execution designers and installation contractors are working off +/- 2mm. Anyone see an issue here?

The simple solution is to assess where tolerances are out of spec, and present this information to the E&M SSC execution designers to mitigate (design-out) the risk. To this end, accurate 3D positional data is required for the thousands of MEH related support items embedded within the MCW structures.

This issue is a long way towards being resolved through the application of 3D point-cloud data-sets which can be analysed using an innovative new software platform called…

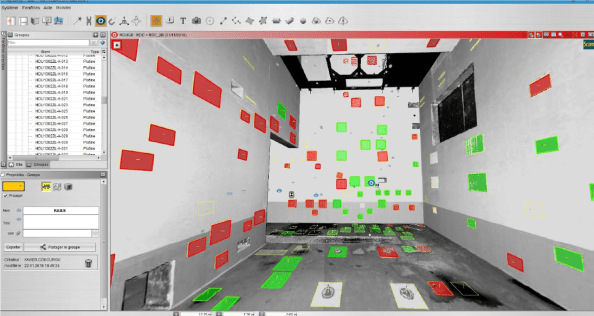

The ‘as-built’ civil structure point-cloud is fed into the software tool alongside the design data for the structure and each embedded item. The software then provides a 3D ‘trueview’ of the structure and will indicate where embedded items are IN or OUT of tolerance using a traffic light system as can be seen in Fig 1. Each component can then be analysed to check its actual position (x,y,z, coordinates). The fact that almost all plates are out of tolerance on the left wall would suggest the wall is probably in the wrong place!

Fig 1. Tolerance analysis of embedded plates within a concrete structure using “My-Survey DAC” by Quadrica

Fig 2. then shows how a deep dive analysis can be carried out for each specific embedded item with clear reference as to where the design coordinates ‘should’ be and where the actual as-built condition has found them to be in reference to the tolerance parameters.

Fig 2. In depth analysis of a specific embedded plate to show design coordinates, actual ‘as-built’ coordinates and deviation from defined tolerances.

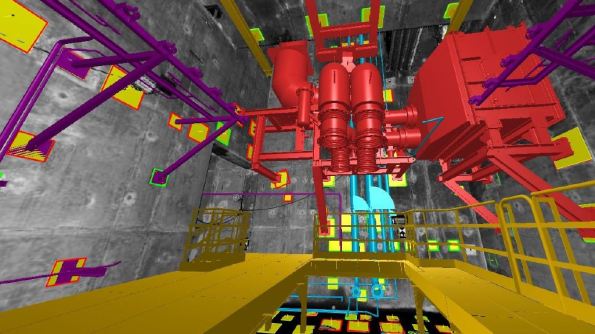

It is also possible to perform CAD model component overlays onto the ‘as-built’ structure as shown in Fig 3. to conduct interface control and to assess the impact of out of tolerance walls, openings, doorways and/or embedded items.

Fig 3. CAD model overlay on to ‘as-built structure’

In developing this methodology, a number of potential benefits have been identified:

- Access to ‘as-built’ data much earlier

- Single point data acquisition, analysis and use. No requirement for SSC installation contractors to conduct their own scans to understand the ‘as-built’ condition

- Early identification of potential problem areas

- De-risk support design and allows for fabrication at source

- Additional cross-project as-built benefits (Lifetime Quality records and Building Information Modelling)

As such a financial saving of £40-60m is predicted throughout the HPC construction from contingency funds associated with risk mitigation.

As well as structural tolerance analysis there are also a number of other applications such as:

- BIM modelling

- 3D CAD/mesh model generation

- Production of isometric drawings

- Volume surveys (earthworks)

- Clash detection

- Final ‘as-built’ survey

- Deformation surveys

- Reverse engineering

- Orthophoto or “Trueview” 3D imagery

- Virtual/augmented reality

- Walk/fly through orientations

Having had to conduct a lot of research before going firm on the “My-Survey” software platform it was surprising how many different software platforms are available on the market now for use in point cloud applications (see Fig 4).

Fig 4. Various point-cloud analysis software platforms

I’d be interested to hear if anyone else is familiar with any and if there are any innovative applications as to how they are being used (turns out I’m writing a thesis on it all?!)?

It’s the way we will go I am sure. The two big players on the list are Autodesk because of the suite that they offer including Revit and Navisworks and Trimble/Bentley who are the other big player and have some interesting hardware offerings through the HoloLens2 technology. I don’t now the shape that your thesis is proposed to take. The MoD are looking at aspects of models and point clouds both for digital battlespace purposes and for construction in all of its different guises so there may be either interest or data to be cultivated. Generally work is being lead by small bands of determined men at the project team level rather than as a corporate engagement. I see this as missing a trick but time will tell. We are trying to ensure future PQEs have at least entry level knowledge of modelling software.