The HAJ waste water treatment facility at HPC.

This will not be as long as any of Mark’s blogs

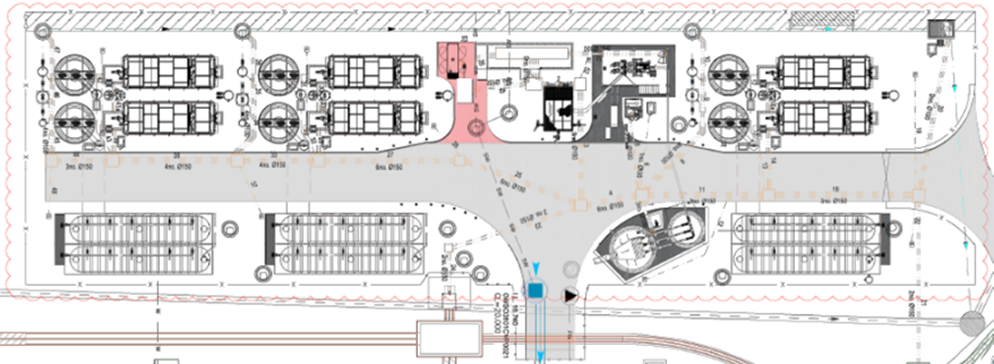

A large part of my time at HPC has been as the construction delivery manager for the temporary waste water facility, known as the HAJ. Designed to accommodate a peak flow of foul water of 33.8L/s for a peak of 9,775 construction workers. It achieves this through the 3 modules each consisting of a Primary Settlement Tank, Rotating Biological Contactor, Final Settlement Tank and a UV filter. Effluent from all 3 modules will flow into a final effluent pump chamber that pumps to a main header tank discharging through a pipeline of the end of the jetty. KBJV are the Tier 1 contracted to complete the Civil and M&E works, they have sub-contracted the main M&E installation to TES, a contractor from Northern Ireland who have in turn contracted much of the electrical work to Mike McDonald electrical services. Much of the plant is of the packaged variety supplied by KEE wastewater treatment technologies.

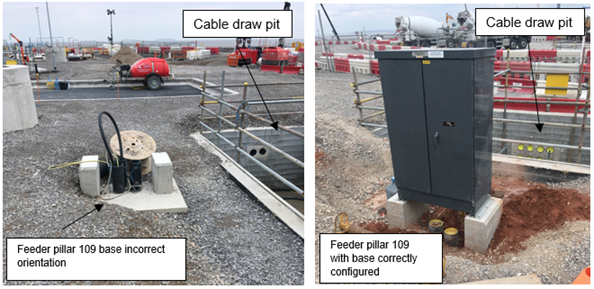

I arrived on-site after the main civil works were complete just in time for the M&E install, when I encountered my first issue (the first of many); feeder pillar 109.

Firstly, the loading profile for the facility was stated as 600kVA requiring 2 x 300mm^2 cables to provide the supply. I noticed this was very large and queried the value with SET, through investigation it was found that this was a typo with only a 60kVA load required. I proposed that one 300mm^2 cable would suffice to meet the demand and allow capacity for any future expansion. The orientation of the pillar was also incorrect as can be seen from the images below and KBJV also used a 90 degree bend which was too tight a radius to allow the cable to be drawn through! TES, the Tier 2 contractor tried to play a contractual game stating that the change in cable size would result in a change in the specification for a number of electrical components within the facility. They did this to try and buy some time as they were (and still are) behind schedule. This was solved buy instructing them to increase the outgoing cable from 95mm^2 to 120mm^&2.

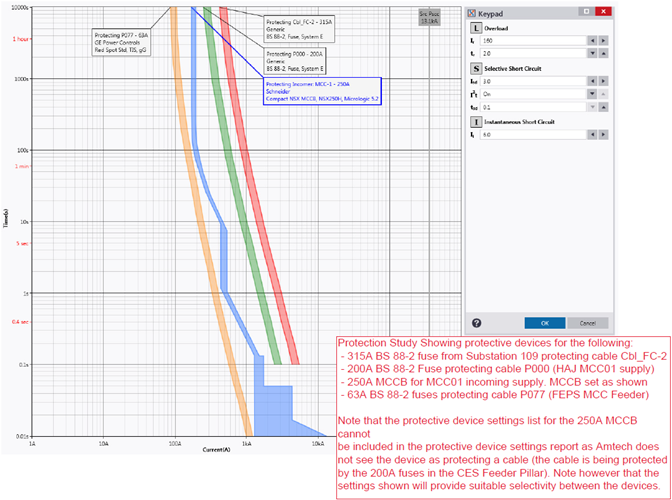

Having changed cable sizes I requested a grading study to be completed, TES and KBJV initially did not see the point, proving the the change in cable size would not cause any issues regarding the protection scheme, seen below. The end result is that all issues were resolved, but I learnt that competent contractors are not really competent and that you have to double check everything.

.

Wow that blue line gets pretty close to the orange one, but I guess as long as they don’t cross over the protection will work in the correct order.

Good stuff and always wise to check! Was there any though to rationalising the cable sizes? 300mm^2 is quite generous for a 60kVA load what were the key drivers for keeping that size despite the dramatic cut in load sizes?

Not my bag but If I were responsible for the civil works I’d be questioning why you couldn’t use two much smaller cables for supply and therefore get around the 90 degree bend without issue. Swapping a protection device at the front end to protect the smaller cables should hardly be a show stopper they are after all off the shelf items and get cheaper as they get smaller but we’ might call it quits on costs given it is a change from originally design!