Archive

Pile Cropping

posted about how his project was using a mechanical pile cropper to remove the excess portion of the driven pre-cast piles. This method is suitable due to the high number of piles and small diameter of the pile head.

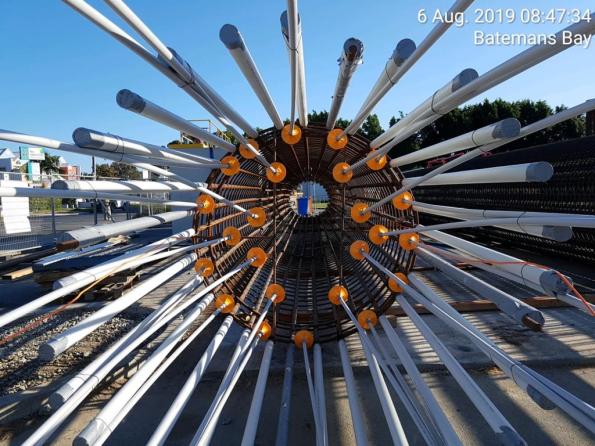

On my project, we have 21 bored piles which vary in diameter between 2.1m and 2.4m. The piles consist of a 16mm thick hollow casing is vibrated into the ground to an established depth. A drilling rig is then used to remove the spoil from within the casing and drill a prescribed depth into the rockhead. When the geotechnical engineer is happy reinforcement cages are secured in place and the piles are poured using a tremie method (to prevent concrete segregation and due to groundwater horizons). This method means that poor quality concrete rises to the top of the pile during the pour (due to laitance) so to compensate the piles are poured a couple of meters higher (‘the overpour’) which is removed as waste concrete. This exposes the reinforcement which is then tied into the pile cap. Due to the large diameter and low number of the piles and the requirement to minimise bending the pile reinforcement a mechanical pile cropping method isn’t feasible.

My project has been using an ‘innovative’ chemical expanding system called Recepieux to break off the overpour at a set level with the overpour lifted off by a crane using pre-installed lifting hooks. This minimises the amount of jack-hammering required pile head and saves a significant amount of time and money. Well at least that is the theory…

To find out more about Recepieux follow these links:

Of the 6 piles the system has been used on so far we have had a 50% success rate. Of the successful breaks, we have struggled to lift off the overpour with a crane so have also used jacks to assist with the removal. A new system on-site often has teething problems and the team have adapted their methods to improve the reliability of the installation, decrease rebar bonding and pre-cutting of the steel casing assist concrete cracking. For the 50% that failed (first 3 piles poured) two weeks of jack-hammering ensued adding delays, noise and dust emissions. The next piles we will be using the system on are marine piles so I’m hoping we have more success as there is limited space for jack-hammers.

Below are some pictures and videos from site:

Recepieux fixed to rebar cage prior to installation inside the casing

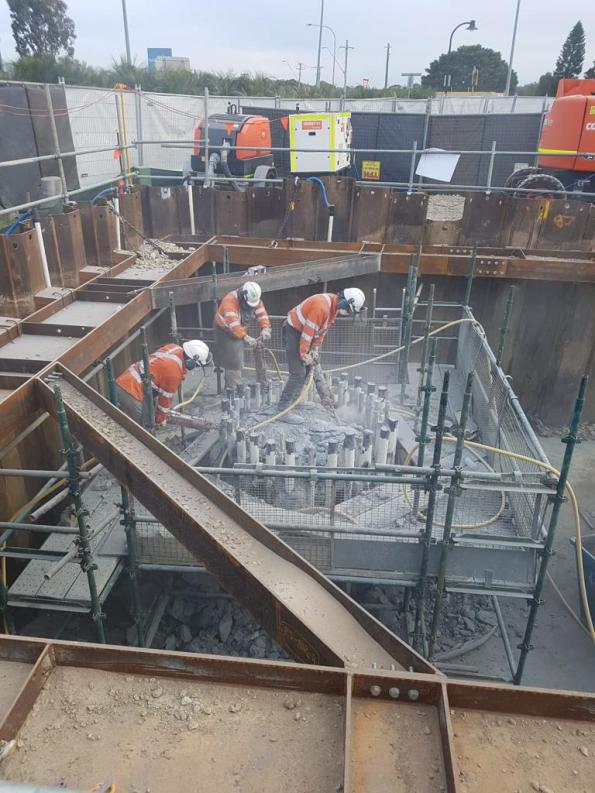

Jack-hammering overpour where recepieux was unsuccessful – increased environmental pollution from noise and dust.

Additional labour costs to remove waste and construct access platforms

Recepieux flasks failed to expand as expected

Expanding grout had not had the anticipated effect

Improvements made to recepieux installation resulting in a crack around pile (note the dark black marks are from oxy-cutting the casing to remove it)

Hydraulic jacks were used to assist removal as the crane could not remove overpour due to the rebar bonding to the concrete

Early stages of jacking

Getting closer 60mm at a time…

Overpour removed

(the video makes it look a lot closer than it was…

a number of H&S issues were improved on)

Rebar exposed after overpour removal. Head of pile cap cleaned up and levelled using manual methods

The following document shows the formulation of the above method by the TWC on site: BBB-VSL-DWG-TW-3054-A-

Concrete Testing – Site Practice?

Does concrete on site get sampled for testing in cylinders, 6″/150mm cubes or smaller 4″/100mm cubes? I ask because, although I know what the BS says, I was recently told that site practice has moved towards using smaller 100mm cubes rather than the standard 150mm. No evidence was offered to support this but I don’t wish to tell someone that they are misinformed without some evidence to support my position. What do you know of your site or others you have visited?

How to demolish around a live substation

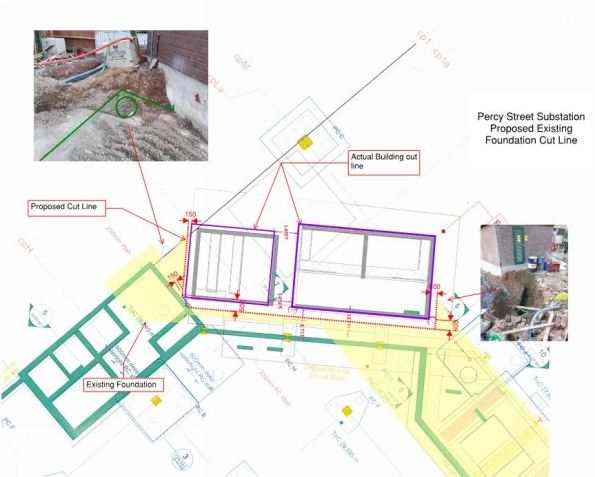

Demolition on my job at Victoria Square, Woking is now almost complete. The demolition sub-contractor are in the process of removing the existing strip foundations, backfilling and creating a piling mat with the site won crushed concrete from the demolished structure.

We have a few risks regarding the interface with adjoinging structures such as the live shopping centre and adjacent construction but none are more sensitive than the live substation on footprint of our demoliton.

The substation was part of the ToyRUs on the first two levels of the previous structure but feeds a large propotion of the shopping centre and therefore must remain live. UKPN who own the substation have dictated that no vibration above a PPV (Peak Particle Velocity) can be achieved above 5 mm/s and there is a vibration monitor fixed to the substation to ensure this.

The problem is the substation sits on the foundation we need to remove and we are creating a signifficant amount of piles and substructure very close to the extent of the walls.

The yellow designates the foundation to be removed and you should also just be able to see the ground beams, pile caps and piles being installed in the coming months. There was the added complication that the exact location of the substation was slightly off during the design of the new structure (compare the grey lines on the drawing to our overlaid purple lines) which make these tollerances even tighter.

The vibration of installing piles so close to the substation is being mitigated by use of a CFA method (although this was always going to be the chosen method anyway as it was selected for the rest of the site) but it still leaves the problem of breaking out a 1.5m deep reinforced concrete foundation 150mm from the substation which isnt allowed to experience vibration. The solution…

Diamond stitch drilling. By using a 150mm diamond drill bit and drilling along a given line around the substation overlapping the holes creates a seperation of 150mm of the foundation under the substation and the foundation to be removed. This is an incredibly slow process with each driller completing less than a metre a day each. With 4 operators on site this will still be nearly 2 weeks work.

In the photo you can see 4 drill rigs set up as the drill out cores of the foundation. It hasnt been raining that soggy foundation is caused by the amount of water used to keep the drill piece cool.

I still have my reservation on whether this will prevent vibration when it comes to removing this foundation considering I feel it in the site office, but it shows we are taking practicable measures to comply with UKPN targets. Whether UKPN have set unreasonable targets is a question for another time I guess, a quick bit of research told me that structures can normally resist up to 20mm/s but I dont have a full understanding of sensitivites to generators or transformers that may be inside.

Changes to Journal access

A little off topic but this is probably the easiest way to get the massage out to everyone in terms of thesis research (well most of you!!). Cranfield have moved from Shibboleth to OpenAthens in terms of sign in for Journals – hopefully you have noticed this and the lack of e-mails back mean that your access is working OK. If it isn’t the case then you can contact libraryresources@cranfield.ac.uk and let them know the sites you are trying to access.

Access to journals will be a crucial part of your thesis literature review so please don’t leave it too late.