Pile Cropping

posted about how his project was using a mechanical pile cropper to remove the excess portion of the driven pre-cast piles. This method is suitable due to the high number of piles and small diameter of the pile head.

On my project, we have 21 bored piles which vary in diameter between 2.1m and 2.4m. The piles consist of a 16mm thick hollow casing is vibrated into the ground to an established depth. A drilling rig is then used to remove the spoil from within the casing and drill a prescribed depth into the rockhead. When the geotechnical engineer is happy reinforcement cages are secured in place and the piles are poured using a tremie method (to prevent concrete segregation and due to groundwater horizons). This method means that poor quality concrete rises to the top of the pile during the pour (due to laitance) so to compensate the piles are poured a couple of meters higher (‘the overpour’) which is removed as waste concrete. This exposes the reinforcement which is then tied into the pile cap. Due to the large diameter and low number of the piles and the requirement to minimise bending the pile reinforcement a mechanical pile cropping method isn’t feasible.

My project has been using an ‘innovative’ chemical expanding system called Recepieux to break off the overpour at a set level with the overpour lifted off by a crane using pre-installed lifting hooks. This minimises the amount of jack-hammering required pile head and saves a significant amount of time and money. Well at least that is the theory…

To find out more about Recepieux follow these links:

Of the 6 piles the system has been used on so far we have had a 50% success rate. Of the successful breaks, we have struggled to lift off the overpour with a crane so have also used jacks to assist with the removal. A new system on-site often has teething problems and the team have adapted their methods to improve the reliability of the installation, decrease rebar bonding and pre-cutting of the steel casing assist concrete cracking. For the 50% that failed (first 3 piles poured) two weeks of jack-hammering ensued adding delays, noise and dust emissions. The next piles we will be using the system on are marine piles so I’m hoping we have more success as there is limited space for jack-hammers.

Below are some pictures and videos from site:

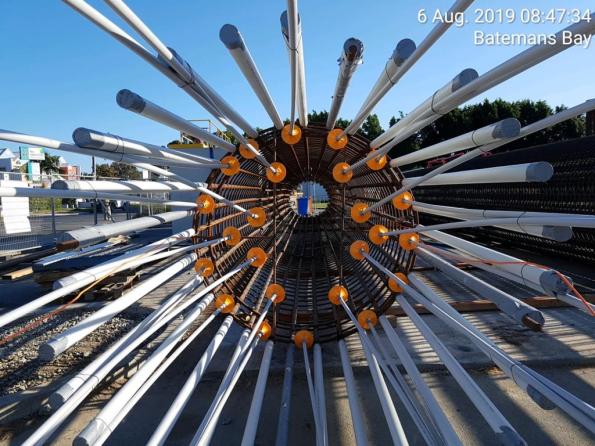

Recepieux fixed to rebar cage prior to installation inside the casing

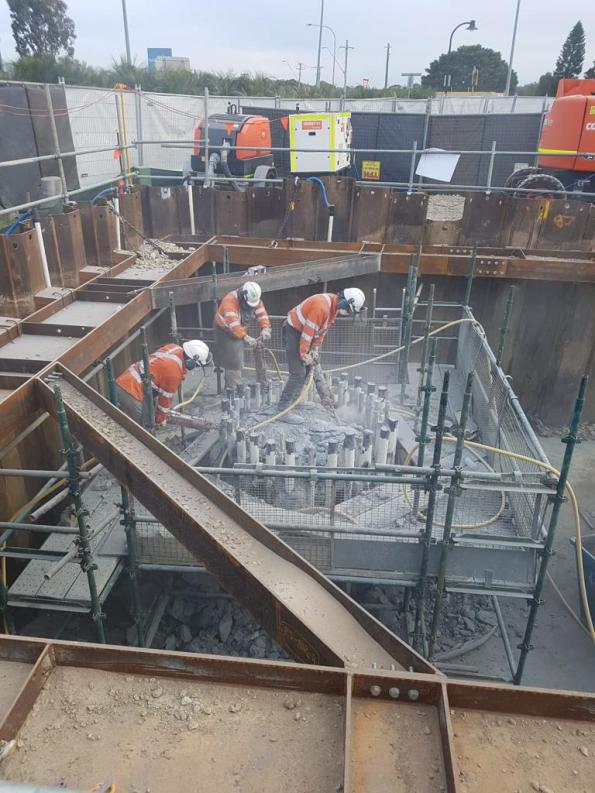

Jack-hammering overpour where recepieux was unsuccessful – increased environmental pollution from noise and dust.

Additional labour costs to remove waste and construct access platforms

Recepieux flasks failed to expand as expected

Expanding grout had not had the anticipated effect

Improvements made to recepieux installation resulting in a crack around pile (note the dark black marks are from oxy-cutting the casing to remove it)

Hydraulic jacks were used to assist removal as the crane could not remove overpour due to the rebar bonding to the concrete

Early stages of jacking

Getting closer 60mm at a time…

Overpour removed

(the video makes it look a lot closer than it was…

a number of H&S issues were improved on)

Rebar exposed after overpour removal. Head of pile cap cleaned up and levelled using manual methods

The following document shows the formulation of the above method by the TWC on site: BBB-VSL-DWG-TW-3054-A-

Thanks Mark. I need to access this at home in order to be able to view the vid links etc. but looks very interesting. Is your take that the system is a good idea that didn’t make the move very well from drawing board to site practice and is not worth the extra effort and cost(?) or that it needs careful delivery but is well worth it in the long run?

The system has apparently been used successfully on smaller diameter piles without a steel casing. The manufacturer is keen to know how it is working on site to see if it is proven to work on large diameter piles. The team on site are removing sections of the steel casing prior to activating the expanding chemical to prevent confining stresses.

In my view the product is being used beyond the manufacturers reference so is essential experimental/a gamble on piles this diameter. If it worked as advertised by the manufacturer it would be fantastic as it would save a lot of time and money. Unfortunately the programme and forecast has been based on the system working successfully so any failures are expensive in terms of time and cost. We have just had further piles fail to detach now out on the water so creates more challenges at short notice due to the environmental constraints.

The gamble is probably worth it however the contingency plan should have been developed in parallel and more detail.