How much civil/structural can an E&M manage?

Hey Guys – I hope to use this blog to pose a problem only – generate discussion, and follow up in comments or a blog to let you know what I did about it.

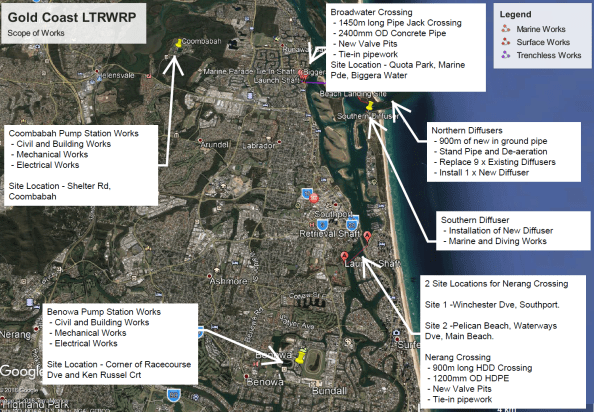

Firstly and briefly – I am attached to the Gold Coast Seaways Project – we are upgrading two pump stations that serve to release recycled water on the Gold Coast out to sea. A map showing project activity can be found below. It consists of two pipelines (northern and southern) and we will have left each of them able to shift future flows of up to 6300 L/s.

Project overview map

And it is in Queensland Australia……

Sorry

Since arriving on site back in April; I have noted that the Engineers on the Project are flat out and separated from one another by geography as well as function. It is almost like 7 separate projects (each headed by an Engineer) rolled in to one headed by the PM. Meaning that interdisciplinary teamwork is difficult at best. I have made good progress in breaking down some of these barriers and managed to get my hands on to some interesting Scopes of Work(SoW), from a range of areas.

However, as a result I have become the go to engineer for that extra little scopes that no-one else wants, some of which I have politely avoided. But I have picked up some pretty interesting little tasks from underwater construction to lifting with no head room. I might pick up on some of those in a later blog; for the time being structural strengthening!

My main task is to deliver mechanical installation at 2 pump stations; I am teamed with an electrical engineer and a mechanical engineer, but no structural engineer. I have some big pumps and motors to move around the place, some of which have been noted by the designer to exceed the load limits of the existing infrastructure and therefore the preliminary work to the main event (the E&M) is a bit of civil and structural.

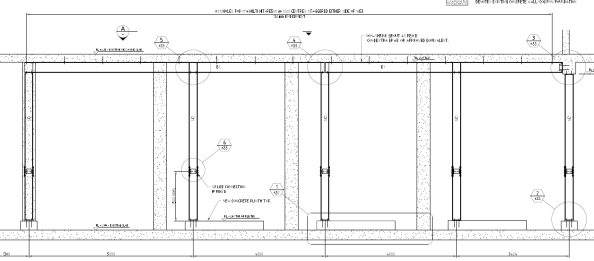

This particular task was to install 5 columns and 2 beams to strengthen the mezzanine floor (drawing below) which will be loaded with the new motors later in the year; no big deal?!?!?

Structural Drawing Snapshot

I was to:

- Read the drawing to put together a scope of works package.

- Submit to potential subcontractors.

- Assess the tenders and award the subcontract.

- Manage the subcontractor through to completion of works.

Problem:

- I don’t know where to start with checking the drawings.

- Any changes I might want to make for practical reasons (clash with my pumps), might not comply with the engineering.

- RFIs raised by the subcontractor will likely push beyond the bounds of PET fundamentals phase.

That said – it’s just management; right? I have done management since joining the Army. This scope is dwarfed by many of the others on the project (magnitude of time and cost) – can I assume that the complexity of engineering is minimal? The designer has already designed it, so I don’t need to do much more than just get someone to fabricate and assemble?

Questions:

- How should I comply with UK SPEC to ‘identify personal limitations, disclose them appropriately and ensure that the implementation of this scope is not hampered by my lack of knowledge’?

- Have you got examples of out of discipline work that you have had to manage?

Finally – it did get installed – and hasn’t fallen down (yet) – so can’t have went too badly.

The Finished Product (anyone spot what’s missing?)

It’s a good one!

Firstly good to see some E&M stuff

Of the first photo … a bit like Chatham then?

Of the ‘spot the missing’ phot. The steel column looks like it’s perched on someone’s shoe!

On the drawing there seems to be a concrete plinth ?

Of the main question….it’s a good one.

I would know what services to expect, where they are likely to run, roughly what sizes to expect. But I wouldn’t know the design details and have been caught out not allowing for bits of baffle and ‘accoutrements’ that were then in the details

Is the converse that you might be expected to understand load paths but not the detail of how the load path is satisfied ( the actual sizing of members in the load path)?

In that, tracing how a load is taken to planet earth and, in particular, avoiding the ‘we need sky hooks’ problem , should, I think , be in your competence.

Oh – it’s worse than Chatham, the sand gets everywhere and I’ve spent a fortune on sun cream.

But absolutely – there is a missing concrete plinth this is because the new pump sit on the same plinth and the old pump is currently in the way. We tabled the following options:

– pour a smaller plinth now and fill in the rest later.

– get the design changed to have the column extend down to the ground (client didn’t like the lack of symmetry).

-extend the hold downs and provide a temporary packing that would be structurally sound until the plinth is poured under it.

-do not load the top until the old pump is removed and plinth poured.

We went with “do not load until pump is removed” – we were in no hurry to load that half of the mezzanine floor; the only reason the steel was installed on that half was to allow for 1 mobilisation of the subcontractor to erect the steel.

It is good that you mention skyhooks – just prior to this photo being taken there was a 10-15mm gap between the beam and the concrete. This was because the hold down arrangement of the existing motors stuck out of the concrete in the line of the beam. This has been filled with grout in the end; although that took about 4 times as long as the steel erection.

Nice post. Thanks Gary.

The missing base is fine just don’t load up until its in and cured. Or is that your new plant perched on top already? Doesn’t look like there’s room for much more up top.

I obviously can’t comment on the adequacy of this deign but I do wonder about the design brief. Was it just that the original structure had a loading limit and the new plant exceeds that so “please design a support” or was there some requirement to check the existing to see if the new loadings were acceptable because old concrete that is in situ has a number of factors than could be reduced and can have a known actual strength applied rather than a design strength assumed.

What are the loads presently applied and how are they carried. and What loads are you planning on imposing on the structure?

Thanks Richard.

The new motor stools are perched on top of the floor – they are within the load limit of the existing concrete columns.

The designer conducted a site investigation to confirm the load limits; I am not sure of the details of that investigation. I do know that the conclusion was that the temporary loading of a number of items were checked and adequate (pipes, valves and motor stools) but that the larger motors (permanently fixed) would not have sufficient support.

To attempt to answer your last questions – There are currently spaces for 4 motors, but only 2 are installed. The load is carried to ground through the existing concrete columns.

We will firstly be installing 2 new motors in to the currently empty spaces. These motors are much larger than the design 30 years ago had allowed for. Once those are installed and commissioned we will remove the existing 2 motors and install 1 more new.

How old is that pumping station equipment?

There a good 30 plus years old…. We are going from direct online motors (either on or off) to variable frequency driven motors. It will make the efficiency of the system better (energy efficiency as well as flexibility of operation) – but has added more complexity to the control system, maintenance and repair regime; the end user will have to learn; we are providing a training plan as part of the hand over to client.

Working for a company like Multiplex this type of management scenario occurs regularly. Apart from the E&M guys, none of the managers currently on my job are qualified engineers, they are all from construction management backgrounds.

The Quantity Surveyors say in this scenario they would take the design, with some basic additional information (working hours restrictions, crane access etc) to the subcontractors and let them create the scope of works which would then be reviewed for compliance. Fundamentally they say the main thing is that the subcontractors/fabricators work is in accordance with the design and specification.

If there are any RFIs or changes then they need to go back to the designer. With Multiplex, we are just the middle man and for insurance purposes anything with the potential to impact on the design must be reviewed by the designer.

That said if possible its always worth getting someone competent to check the design for completeness or any obvious errors. For example through a drawing review we spotted a secondary steelwork company was about to fabricate a stair the wrong way round and that an insufficient fire rating was being included.

All the management stuff around this is just the normal, quality, logistics, safety, coordination with other work etc, no different to your normal E&M stuff.

I feel similar at times with regards acting as the “middle man”. I think there are opportunities to stretch my understanding of the structural scope; but I am always conscious that I don’t make technical decisions.

I instead try to push the designer in a direction that is most advantageous to the needs of my scopes – but always trying to invite others for comments so I don’t force the design change that causes problems for others. An example is that I am not responsible for the electrical cable runs that go through the pump station – they have a habit of trying to put cable trays in the way of the mechanical spindles or actuators – fortunately we manage to pick most of that up prior to install.

To close:

Firstly; I found the career overview and subsequent AERs useful in identifying where my strengths and weaknesses lay. I also found that a review of the syllabus alongside my notes from phase 1 aided me refreshing my memory and helped me articulate what I was capable of.

I discussed my limitations with my immediate supervisor (Electrical Engineer) and the Construction Manager (Structural Engineer). I then kept the majority of my dealings with the scope to “management” decisions and had all engineering decisions (even the minor ones) reviewed by the Construction Manager as a minimum. One decision that comes to mind was the decision to install in 2 halves – would the half we were installing sufficiently take to load to ground or did it rely on the other half to share the load. This was a performed by a design review conducted by the construction manager and the designers – I was present in the meeting to discuss the administrative elements of achieving the work; but was not involved in the technical decision making.

Finally; thanks for sharing your views – hope to share some more shortly.