Archive

Australian Fires

Hopefully this post will keep the E&Ms happy as it has nothing to do with engineering!

Some of you will have seen the Australian Bushfires on the news and just flicked past the articles without too much thought.

A few weeks ago, the fires were particularly bad west of Sydney, causing the air quality in the city to be equivalent to smoking 40 cigarettes a day.

Most of the Australian countryside is like a tinder box with high temperatures and little rain making it perfect conditions for the fires which have continued to spread. Last night strong winds and dry lightening storms added to the number and scale of the fires. (The winds were so strong a volunteer fireman was killed when the wind lifted and overturned his 10t truck).

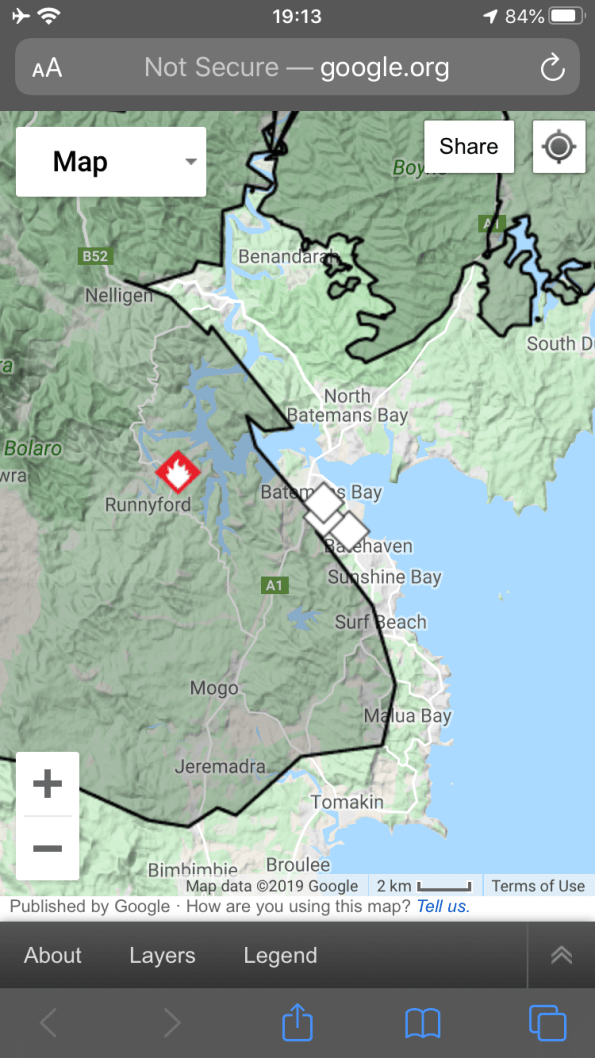

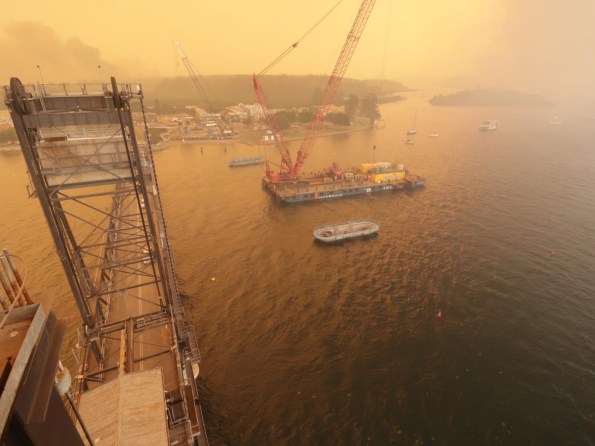

This morning we got a text alert notifying us of an emergency fire situation in Batemans Bay where my site attachment was (we moved down to Melbourne 4 weeks ago). I viewed the online fire tracking website which showed the town is practically cut off by fires. This prompted me to log onto my old project time-lapse cameras to take a look. (Pictures taken one daylight and links below).

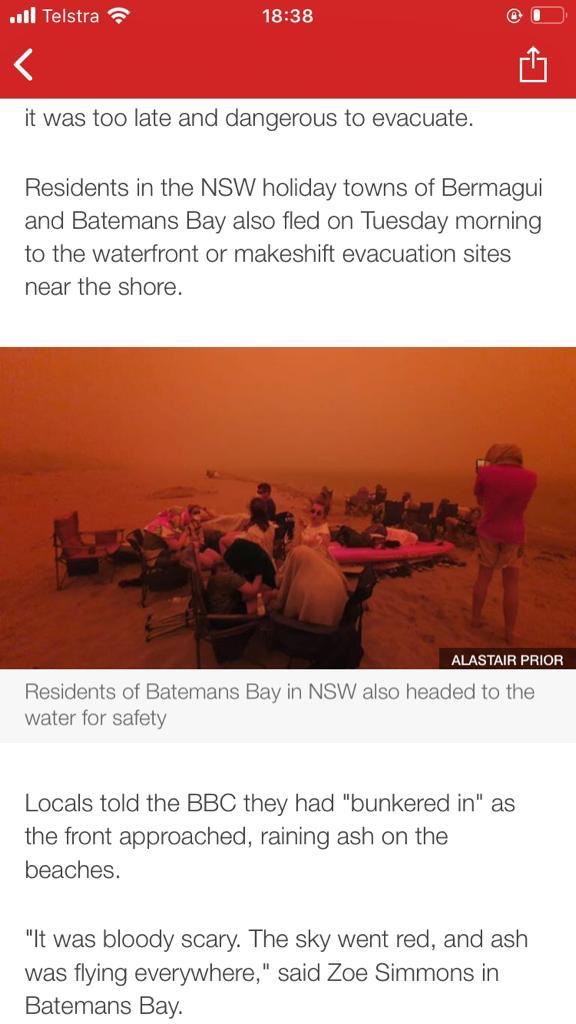

Today a picture from Batemans Bay has made BBC news and is probably one of the headlines you are waking up to this morning. It is difficult to describe the scale and impact of the devastation from the fires.

Currently there is no works on the project site due to the Christmas shut-down. Hopefully the situation will have improved in a weeks time when the site re-opens.

Sadly the fires are like this along most of the coast from the Queensland boarder in the north to parts of East Victoria in the south. All PET students are safe in cities and ready to see in the new year in Australian style.

Wherever you are and however you are celebrating I wish you all a happy new year from Australia.

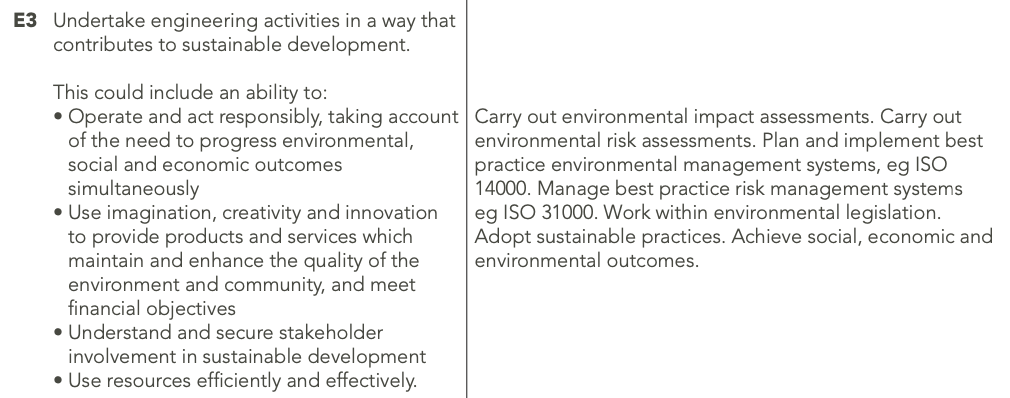

UK Spec – Sustainable Development

Jambo’s comment on A Blog on Blogging below has actually given me the inspiration for my first blog!

Working over in the ‘freest country on earth’ sustainable development just hasn’t come up as an area to gain experience. In order to be so free Americans avoid Federal Government ‘meddling’ as much as possible leaving it to the states and individual counties, which business then takes advantage of. Examples can be easily found in H&S as well as environmental impacts of how this can cause a race to the bottom in certain areas.

The only time I have seen sustainable development is a tick box form to question if light bulbs meet minimal efficiency standards and if the manufacturer uses sustainable methods where Unknown was an acceptable answer. This form was a requirement as it is a government contract however nobody was interested in the answers, just that the form was complete.

How are others getting on with this competence?

Is sustainable development taken seriously in the UK and Aus, or just individual projects (if at all)?

@bnrbwoods, I expect BP aim to have buzzwords like sustainable development covered off to help with their image? Is this realistically a tough sell?

Merry Christmas and Happy New Year all!

A blog on blogging…

The PET Blog so far for me has been a scary place, full of complex Civil treatises about mud and concrete. So I questioned – what do PEW want from a blog?

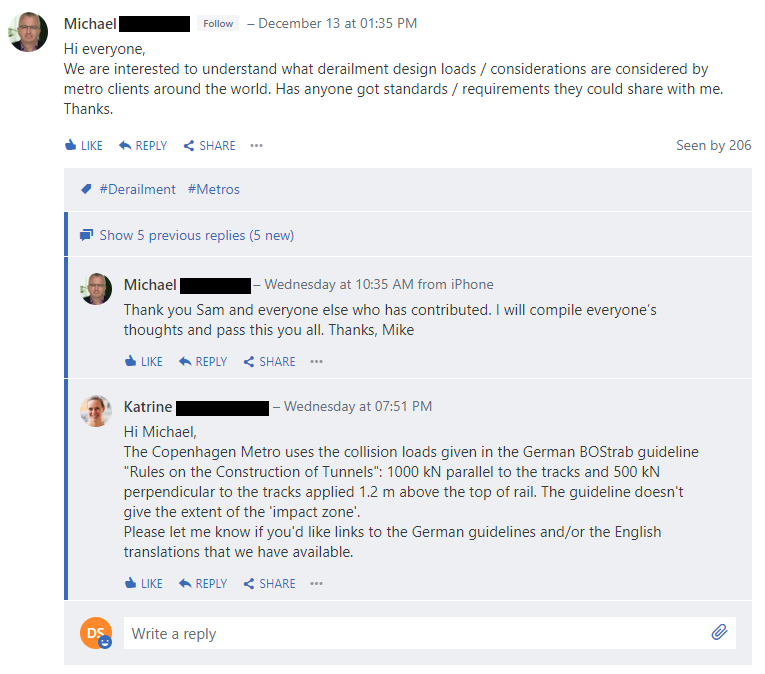

Now that I have moved to Phase 3, I’ve discovered a similar concept at Arup. Called ‘Yammer’, it seems to be an avenue for the sharing of short dits that could be useful across multiple project disciplines, or to succinctly frame a problem and ask for advice from across the company. Being a much larger organisation (c.14,000 personnel), the blog is split by discipline/area and includes Project Management, Building Services, Bicycle Users Group etc etc.

Arup blog examples from ‘Yammer’

It has made for some interesting reading and has demonstrated, at least for me, how useful a blog could be as a knowledge sharing device. The short, quick nature of their posts takes little from their day, but the benefit is obvious. I also think that keeping it short promotes involvement from a wider audience. But this is just their way of doing things.

I’d be interested to hear what you guys think about what the PET blog should be – What do we want from it? Is it being used in the best way? How should we be using the blog? Should we set Cheese and Groom a word limit?

Have a good Christmas and NY! Back to the beach…

Geopolymer “Earth Friendly” Concrete

It is well known that the production of Portland cement (OPC) is highly damaging to the natural environment. It is high in embodied carbon and embodied energy and its production creates noxious waste emissions – globally, production of 1 tonne of OPC produces roughly 1 tonne of CO2. Reducing the OPC content of concrete mixes has been standard practice in construction for many years, through the use of cementitious replacement materials such as blast slag (e.g. GGBS) or fly ash (e.g. PFA) derivatives, but an Australian company is now marketing a geopolymer based concrete which contains no OPC at all.

EFC pavement

Wagner’s Earth Friendly Concrete (EFC) uses an alkali chemical powder to activate other pozzolans – cementitious content (GGBS and PFA) – to achieve the binding effect of cement. If you accept that GGBS and PFA are waste materials (which is a separate topic) then EFC can see 80-90% reductions in carbon carbon emissions when compared to a full OPC mix.

Crucially, this product is now able to match concrete in many applications and appears to be commercially viable. The fine and coarse aggregate content remains the same in terms of performance it shows:

- 30% higher flexural strength

- Very low heat of reaction

- Very low shrinkage

- High sulphate resistance

- High chloride ion ingress resistance

- High acid resistance

There are a number of case studies available (wagner.com.au) which show good performance in pre-casting and pavements in particular (including airports) with an interesting foray into sewer tunnel lining. The low reaction heat, leading to low shrinkage, is an ideal characteristic for pavements (especially I imagine in Oz where curing must be tricky in the heat?) and the high resistance to chemical attack makes it a good choice for sewers or other corrosive environments. It even has a clean white finish.

EFC precast

There certainly seems potential for use in the UK in mass concrete applications at least e.g. piling and ground bearing slabs, but I haven’t seen much evidence yet of it’s use for in-situ superstructure pours. I imagine this is a result of the low reaction heat leading to longer curing times (or vice versa at the chemical level). In a concrete frame longer curing means longer shuttering, more back-propping and slower jumps between floors – i.e. it means money – but this doesn’t apply so strongly to unpropped steel decking (composite) slabs so perhaps there is potential there too.

Has anyone seen this in use yet, especially you guys Down Under?

The return of the most expensive cube of grout

Refresher

In my earlier blog on the most expensive cubic metre of grout ever poured I ended with a hope… and a contingency.

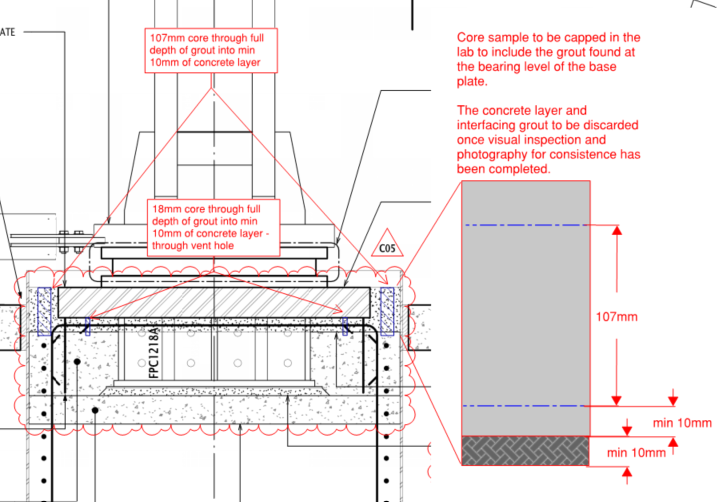

Taking core samples from suspect grout

The hope was to take core samples from the suspect grout on the chance that the in-situ strength was higher than the cube test results which had returned compressive strengths of <40MPa after 14 days (less than half the forecast strength at this age). The design consultants had worked around the clock (literally – Robert Bird Group enlisted one of their New Zealand based engineers to work the opposite hours to the UK team) to prove the scheme with a minimum grout strength of 50MPa.

Core Samples

100mm samples were taken where we could get at the face of the grout and clearly showed the separation that we feared.

As you can see in the photos above the grout has separated and the fine aggregates (<2mm sand) have settled to the bottom. The smooth grey upper section contains the majority of the cementitious content and the chalky white crust on top is the synthetic polymer additives. The granular layer was so weak several of the samples sheared in half during extraction revealing the cross-section above.

Testing

The specimens were sent for testing (which by the way takes a lot longer than cube testing due to the time required to prepare and cap the samples) and strength results were issued. We asked for testing of the lower sections of the specimens as this is where the bearing surface is and where we suspected the lowest results.

For the two samples in the left hand photo we received cube equivalent compressive strength results of 17 and 15.2 MPa. On one slightly longer sample we were able to test both the bottom granular section and the upper smooth section. This test returned 37.3MPa in the aggregate and 70.6MPa in the cement matrix. This again supported the theory of complete segregation due to over-watering of the mix.

For anyone coming across a similar situation I have uploaded a document summarising viable In Situ Testing Techniques.

Conclusion

Instruction was issued that all affected grout was to be removed by hydro-demolition and replaced with only a month long window in order to avoid knock-on critical path delays to the project as a whole – a certain contender for the title of world’s most expensive grout.

Can you trust a contractor?!

Just a quick question really guys, have any of you trusted the contractor to work to their own ITP. It might seem strange but during my site attachment the contractors were loathe to follow their own contractually agreed documents. I was just wondering if any of you had any issues?

Failure is sometimes an option

As a cohort we have just moved onto Phase 3. I am in my second week at a temporary works design office for BAM Nuttall. To get myself acquainted with the team and some design work, I have been given checking duty for a number of designs. The one I am posting about is a temporary working platform for a sheet piling operation.

The design is for a platform for a piling rig and crane to both travel and work on. The platform has been split into two requirements a haul road and working platform. The contractor specified they wanted to use bogmats (100mm timber planks) instead of aggregate due to the logistics on site. The working platform was designed with 1 layer of bogmats for the whole and 2 layers under the crane outrigger positions.

The checks are conducted simply by calculating the load and subsequent pressure (depending on contact area) on the tarmac and sub-grade and comparing it with their bearing capacity. If the material fails, a layer of bogmats are placed on top and then a recalculation is done with a layer of bogmats to aid distribution of force and hence lower pressure. In the case of the crane outriggers a second layer was needed as the pressures were still beyond the capacity of the soil. There are load cases and partial safety factors but as it is not important to the blog I will not detail them.

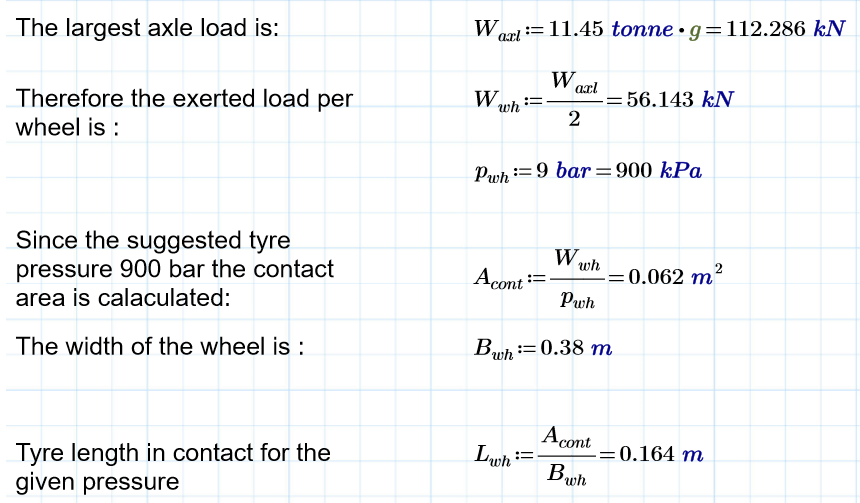

An interesting case was determining whether the tarmac haul road needed bogmats or not. The piling rig passed easily because the travelling load is much lower than that of the working load and the large tracks distribute the load onto the tarmac adequately. The crane, however, with its wheels had a much larger pressure.

This amounted to a 921 kPa pressure on the ground. To put this in context the piling rig exerted a 70 kPa pressure.

The ultimate bearing capacity of the tarmac was calculated at 411kPa and therefore failed. This was not all as bad as it seems however. The design continues to assume a 50mm deformation of the 150mm tarmac layer. This sinking of the tyre actually provides a larger contact area between the tyre and the ground. This not only gives a smaller pressure due to the same load being distributed over a larger area, but changes the shape factor in the bearing capacity equation giving a better capacity. After re-modelling the bearing pressure reduced to 290kPa and the bearing capacity of the tarmac increased to 870kPa meaning the crane passed.

This seemed like it was riddled with assumptions to me. Firstly, how do we know the tarmac is deforming 50mm? It was not calculated, it was purely an assumption made. Secondly, how do we know this deformation is purely elastic and wont leave the road rutted after use? I took my queries to the senior designer and he stated that considering the crane is a tracked vehicle it will arrive to site on a tarmac road and it can be assumed the tarmac on site is not dramatically different to that on a road and if the tarmac on the road can take it, the risk is low. Also given the crane is just travelling the risks of any serious incidents should the soil fail are also very low. I didn’t like how the capacity of the ground had doubled from 411 kPa to 870 kPa purely by the load being “embedded” into it. These came from a spreadsheet held within BAM which basically just computes the coarse soil bearing capacity equation :

![]()

This to me is “grey-box thinking” where the engineer who initially designed this, did not necessarily know what he was computing, just the inputs required. Ultimately, I might not feel fully comfortable with the results of the spreadsheet, but I am comfortable with the senior designers assurance that the risk of this particular activity, compared to the rest of the working platform is low. A potential risk to be highlighted in the designers risk register and nothing more.

I guess there are ways of meticulously modelling and calculating all of this but the balance of risk and temporary nature of the platform meant these assumptions and risks were tolerable enough to not bother. It is an interesting study on balancing the design risk with the time (and therefore cost to BAM) to reduce it.