Archive

Failure is sometimes an option

As a cohort we have just moved onto Phase 3. I am in my second week at a temporary works design office for BAM Nuttall. To get myself acquainted with the team and some design work, I have been given checking duty for a number of designs. The one I am posting about is a temporary working platform for a sheet piling operation.

The design is for a platform for a piling rig and crane to both travel and work on. The platform has been split into two requirements a haul road and working platform. The contractor specified they wanted to use bogmats (100mm timber planks) instead of aggregate due to the logistics on site. The working platform was designed with 1 layer of bogmats for the whole and 2 layers under the crane outrigger positions.

The checks are conducted simply by calculating the load and subsequent pressure (depending on contact area) on the tarmac and sub-grade and comparing it with their bearing capacity. If the material fails, a layer of bogmats are placed on top and then a recalculation is done with a layer of bogmats to aid distribution of force and hence lower pressure. In the case of the crane outriggers a second layer was needed as the pressures were still beyond the capacity of the soil. There are load cases and partial safety factors but as it is not important to the blog I will not detail them.

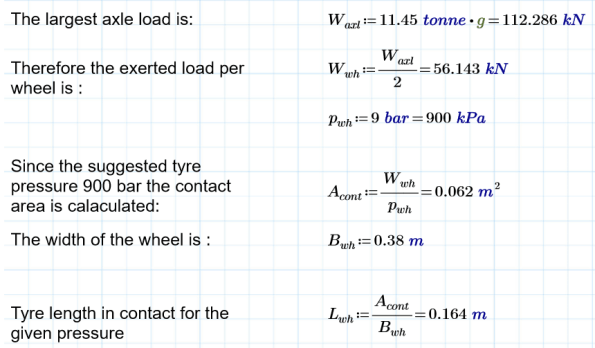

An interesting case was determining whether the tarmac haul road needed bogmats or not. The piling rig passed easily because the travelling load is much lower than that of the working load and the large tracks distribute the load onto the tarmac adequately. The crane, however, with its wheels had a much larger pressure.

This amounted to a 921 kPa pressure on the ground. To put this in context the piling rig exerted a 70 kPa pressure.

The ultimate bearing capacity of the tarmac was calculated at 411kPa and therefore failed. This was not all as bad as it seems however. The design continues to assume a 50mm deformation of the 150mm tarmac layer. This sinking of the tyre actually provides a larger contact area between the tyre and the ground. This not only gives a smaller pressure due to the same load being distributed over a larger area, but changes the shape factor in the bearing capacity equation giving a better capacity. After re-modelling the bearing pressure reduced to 290kPa and the bearing capacity of the tarmac increased to 870kPa meaning the crane passed.

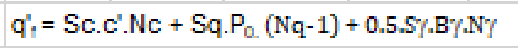

This seemed like it was riddled with assumptions to me. Firstly, how do we know the tarmac is deforming 50mm? It was not calculated, it was purely an assumption made. Secondly, how do we know this deformation is purely elastic and wont leave the road rutted after use? I took my queries to the senior designer and he stated that considering the crane is a tracked vehicle it will arrive to site on a tarmac road and it can be assumed the tarmac on site is not dramatically different to that on a road and if the tarmac on the road can take it, the risk is low. Also given the crane is just travelling the risks of any serious incidents should the soil fail are also very low. I didn’t like how the capacity of the ground had doubled from 411 kPa to 870 kPa purely by the load being “embedded” into it. These came from a spreadsheet held within BAM which basically just computes the coarse soil bearing capacity equation :

This to me is “grey-box thinking” where the engineer who initially designed this, did not necessarily know what he was computing, just the inputs required. Ultimately, I might not feel fully comfortable with the results of the spreadsheet, but I am comfortable with the senior designers assurance that the risk of this particular activity, compared to the rest of the working platform is low. A potential risk to be highlighted in the designers risk register and nothing more.

I guess there are ways of meticulously modelling and calculating all of this but the balance of risk and temporary nature of the platform meant these assumptions and risks were tolerable enough to not bother. It is an interesting study on balancing the design risk with the time (and therefore cost to BAM) to reduce it.