Home

> Uncategorized > Cost of Over-specification

Cost of Over-specification

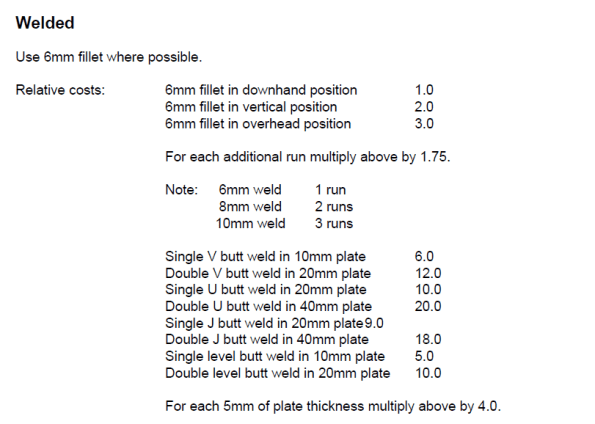

Below is a document from Arup regarding weld sizes and the unit cost associated with them.

As you can see a 6mm fillet weld has a unit cost of 1. If the weld is increased to a 10mm fillet weld to be on the safe side then straight away the cost rockets to 3 times the price. Therefore a designer should always be conscious of the strength requirements of welds to ensure they are sufficient throughout their working life and even when corroded, but we should also be conscious of the cost implications that come with over-specifying.

I just thought that this was a quick illustration of how even simple engineering decisions can actually dramatically increase the price of seemingly innocuous elements leading to a costly design.

Categories: Uncategorized

Do I detect a budding QS in the making.

A really nice piece

So try to avoid FPBW and do everything with the smallest fillet possible in the shop (so downhand)

Jon,

I actually designed a weld today. The size of the weld chosen depended upon the size of the SHS I chose and the strength of steel used. In my case, for a 70mm SHS a 9mm weld was needed, for 75mm an 8mm weld and for a 90mm SHS a 6mm weld. As it hapens, I chose to balance the cost of the weld and the increased section size. Deffinitely a good consideration for a designer to have in their pocket!