Archive

Temporary Works Tour: 1-5 Grosvenor Place

I recently visited a project in London where Sir Robert McAlpine Design Group are the temporary works lead. The project is to build a new hotel/apartment building near Hyde Park at 1-5 Grosvenor Place for Hong Kong and Shanghai Hotels. The building comprises 9 floors above ground and four to five basement levels below. As the basement construction period is significant due to the complex below ground structures, and the volume of material to be excavated and removed from the basement, the method of construction has been ‘top down’. This allows for the basement to be excavated and constructed concurrently with the superstructure construction and fit-out above, with savings to the programme. The building comprises four reinforced concrete ‘cores’ in each quadrant of the building which provide the main vertical access with a central courtyard in the centre. The central courtyard is currently used as the access for plant and material to the basement levels during construction, but will be covered by a garden on completion. The main structure has been completed with the first floors now being clad. The last two floors of the basement are currently being excavated down to approximately 20m below ground level.

The temporary works on this project have been significant and I thought I would show the extent of them here. At each core of the building a crane has been placed on the roof. Placing cranes on the cores allows the building to be substantially completed and made watertight without having a void through the building for the tower crane mast. This has required a temporary works solution to provide a base to fix the crane. The supporting concrete core has been designed and enhanced to withstand the tensile stresses caused by the crane which has required bursting steel reinforcement. Note also the long post stressed threaded connections which are required to take the tensile stresses of the crane.

The site itself is very restrictive with very limited space for site offices. The solution has been to construct offices cantilevering out over the adjacent carriageway with a steel frame to support the offices above. To limit the loading on the pavement on which it is founded, a reinforced concrete raft has been cast over the pavement. Access positions have been required at any existing manhole or service cover locations. Further resistance to overturning has been provided by casting holding down bolts into existing grouted or concrete filled vaults below. The limited space has also required a solution for site traffic. This has been overcome by constructing a temporary steel structure to support a ramp and bridge through the courtyard of the building.

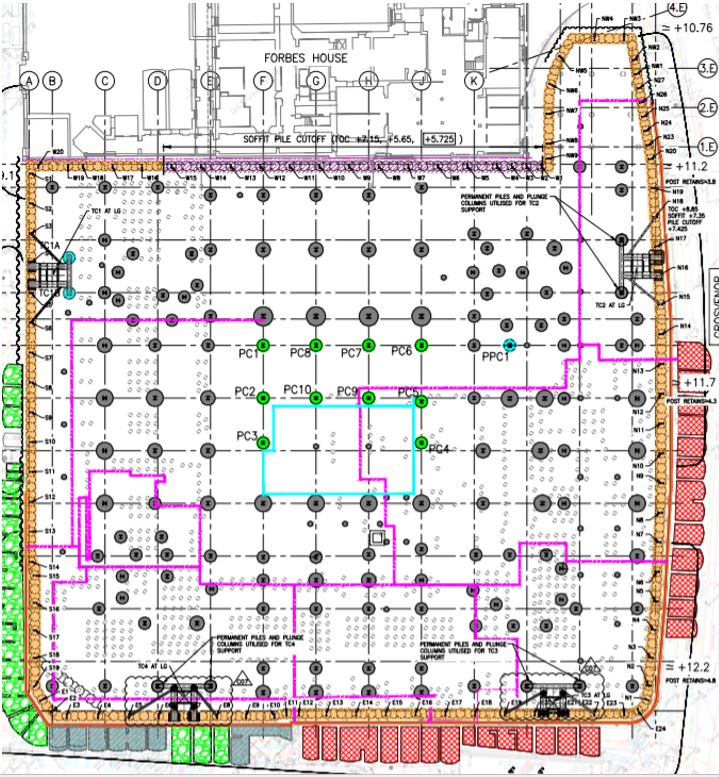

The steel structure is supported by large plunge columns that will eventually be removed and cut at pile cap level (see columns highlighted in green in the drawing below). The ramp and bridge allow site traffic to enter one side of the building and exit the other. A telescopic clamshell bucket shown in the image above is able to extract the spoil from the basement levels below and load it onto trucks passing over the temporary road structure.

At basement level 1.2m diameter secant piles have been installed around the whole perimeter of the site (orange above). In particular propping has been required to strengthen the piling on the west end of the site where another building abuts the site closely (purple line above). This has been to limit the deflection of the secant piles and therefore limit the effects on the adjacent structure. Inclinometers have been installed down the length of these piles to monitor any significant deflection.

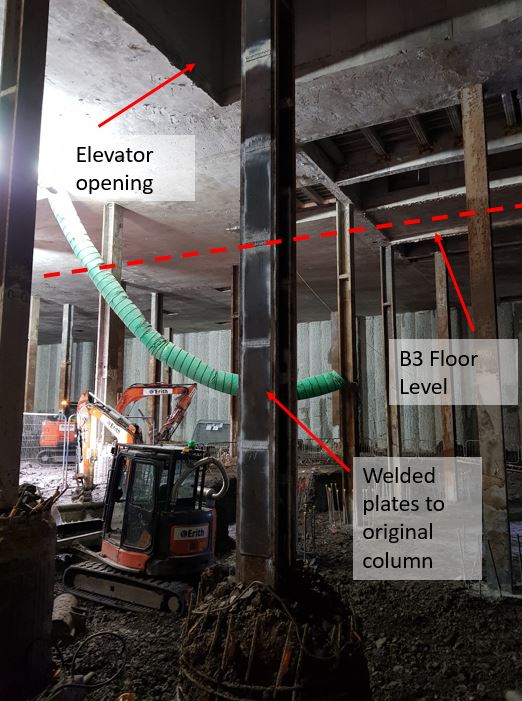

The basement is currently being excavated over the final two floors. This has been in order to enable large sized plant to operate and to allow removal of adequate volumes of clay per shift. Originally the design of the building only included three basement floors as planning permission for a fourth had not been granted during the design phase. However, later during construction a fourth basement floor was approved. This caused an issue with some of the existing columns that had already been installed. They would be too slender to take the loads from above in the temporary state before basement level 3 had been constructed. The increase in effective length between B2 and B4 level meant that some of the columns would need to be modified. In the image below shows where additional plates have been welded to the flanges of the columns to make them stockier and reduce their slenderness ratio.

The columns at higher level were originally to be encased in reinforced concrete. However, this has recently changed as the client now wants a masonry finish to the columns. This means that the cross sectional area of the columns are reduced, thus a reduction in the second moment of area. My involvement with this project so far has been to evaluate whether the columns are able to still take the axial loads without this reinforced concrete encasement.

This demonstrates the significant amount of temporary works involved in a project of this size, especially in a congested site like London. This offers some excellent opportunities for an engineer to get experience on a wide variety of engineering challenges.