Archive

Don’t forget the drain

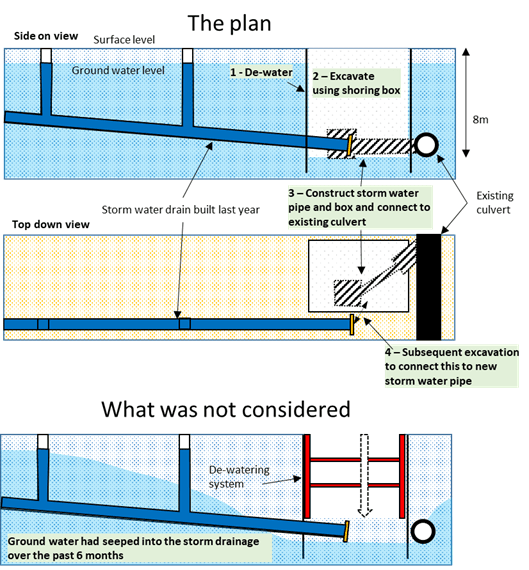

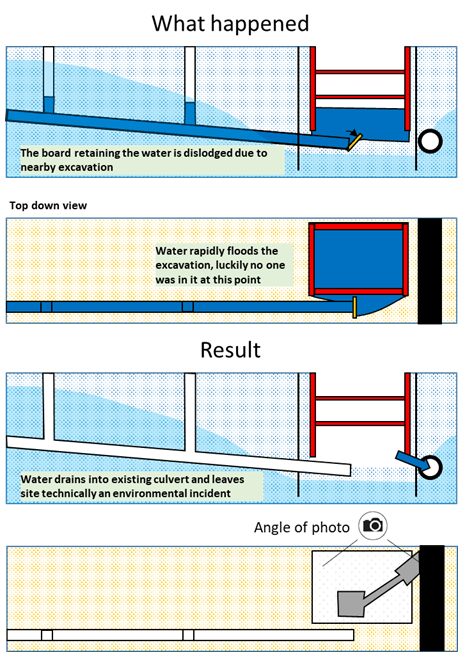

An excavation on my site unexpectedly flooded the other week. It was to connect into an existing storm water culvert at about 8m below surface level, thankfully no-one was in it at the time.

This could have easily been prevented by pumping out the water in the storm water line. It was simply an oversight by the engineers planning it.

As the ground water is contaminated (heavy metals among other things) and this water counts as waste water from a construction site this is also a reportable environmental incident.

Guess the lesson here is not to forget about what you have put in the ground… and maybe check your drains.

An NHS View On ‘Military Planning’

I stumbled across an interesting perspective on ‘military planning’ in the British Medical Journal here: https://www.bmj.com/content/369/bmj.m2055. It offers a valuable external perspective on how we work, plan and operate which should serve as a useful reminder for those who are growing comfortable in their civilian attire. Have a read, and for those in Ph3 moving to Ph4 it will serve as a timely reminder and look forward to….

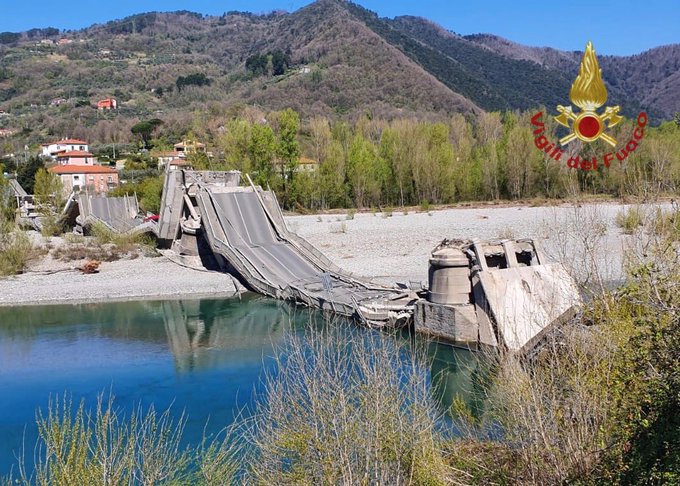

Italian Bridge Collapse / Textbook Demolition Job

Thanks to lockdown in Italy only 2 people were injured when this 240m bridge collapsed at the beginning of April and, perhaps as a consequence, it has seen less media coverage than the Genoa motorway bridge collapse in 2018.

The bridge had six 40m RC arch spans between stone piers. All spans collapsed completely and at least two of the five piers were toppled in the process leading to a pretty thorough demolition job.

The state of repair of the Italian road network is clearly under considerable scrutiny and it seems likely that this bridge collapse is, at least in part, due to poor inspection and maintenance. Cracks appearing in the deck can be seen on street view and have been growing since 2011. These cracks were inspected in 2019 but no action was taken. Read more…

Air do we go from here?

In the coming weeks it looks like we will begin the return to normality and to start occupying the spaces that have been the reserved for the essential workforce. As the built environment begins to take higher occupancy levels there is a need to deal with the risk of a person-to-person transmission of Coronavirus.

It is generally accepted that when a person coughs/sneezes/talks the Coronavirus pathogen is spread in one of two ways. The expelled droplets either behave ballistically and land on another person/surrounding surface or the droplets are aerosolised and are subject to air-buoyancy effects. The later of these mechanisms is where HVAC systems play a key role in controlling infection.

Given the novelty of the Coronavirus there still exists considerable conversation over how best to manage the ventilation systems of occupied spaces in order to reduce this risk. I have collated below the information from key groups (CIBSE, PHE, REHVA and ASHRAE). As you can see there exists conflict around topics such as RH and ventilation rates. I would be interested to know if there are any other individuals who are dealing with the same risk and having to implement a new or revised HVAC/building utilities strategy.

| CIBSE: CoVID-19 Ventilation Guidance (Summary) v1 9 May 20 Well ventilated rooms dilute pathogens and poorly ventilated areas carry a higher risk of airborne transmission Fine aerosols (from coughing and sneezing) remain airborne for several hours Duct cleaning has little or no effect on the prevention of spread of pathogens Specific guidance: Open doors and windows as much as possible to increase natural ventilation. Keep WC windows open as much as possible Maintenance staff to wear adequate protection when changing filters on A/C units Avoid recirculation where practicable Heat recovery devices in AHUs to be turned off |

| Public Health England: Infection prevention and control guidance – 27 Apr 20 “In light of limited data for SARS-CoV-2, evidence was assessed from studies conducted with previous human coronaviruses including MERS-CoV and SARS-CoV. Human coronaviruses can survive for up to 5 days at temperatures of 22 to 25°C and RH of 40 to 50%. The rate of clearance of aerosols in an enclosed space is dependent on the extent of any mechanical or natural ventilation – the greater the number of air changes per hour (ventilation rate), the sooner any aerosol will be cleared. The time required for clearance of aerosols, and thus the time after which the room can be entered without a filtering face piece (class 3) (FFP3) respirator, can be determined by the number of air changes per hour (ACH) as outlined in WHO guidance.” Specific guidance: “…A single air change is estimated to remove 63% of airborne contaminants, after 5 air changes less than 1% of airborne contamination is thought to remain. A minimum of 20 minutes (recommend 2 air changes) in hospital settings where the majority of these procedures occur is considered pragmatic” |

| REHVA: CoVID-19 Guidance document (Summary) – 3 Apr 20 Large and small particles (aerosols) are ejected from an infectious person. It’s the latter which are of concern for HVAC systems. Well ventilated rooms dilute pathogens. Poorly ventilated areas carry a higher risk of airborne transmission Heat recovery devices in AHUs usually work poorly and leak. Areas which have comfort cooling or heating need intervention. RH has little or no effect virus susceptibility. Specific guidance: At nights and weekends, do not switch ventilation off, but keep systems running at lower speed Ensure regular airing with windows (even in mechanically ventilated buildings) Avoid open windows in toilets to ensure the right direction of ventilation. Mechanical ventilation to run 24/7. Instruct building occupants to flush toilets with closed lid Switch air handling units with recirculation to 100% outdoor air or 400 ppm max of CO2 Do not plan duct cleaning for this period Regular filter replacement and maintenance works must be performed with PPE including respiratory protection Maintain social distancing measures to guard against person-to-person transmission |

| ASHRAE: Position document on infectious aerosols (Summary) – 14 Apr 20 “…Even the most robust HVAC system cannot control all airflows and completely prevent dissemination of an infectious aerosol or disease transmission by droplets or aerosols. Ventilation with effective airflow patterns is a primary infectious disease control strategy through dilution of room air around a source and removal of infectious agents. However, it remains unclear by how much infectious particle loads must be reduced to achieve a measurable reduction in disease transmissions.” Specific guidance: Air distribution patterns have an effect on distribution of aerosols Differential room pressurization can influence air flows Higher efficiency filtration (MERV-13) reduces concentrations of aerosols Increase outdoor ventilation as close to 100% as possible, 24/7 UV light with 265nm wavelength provides a good germicidal effect RH of between 40 and 60 RH is optimal for reducing microorganism survival Bypass energy recovery systems |

| World Health Organisation – Getting your workplace ready for CoVID-19 (Summary) – 3 Mar 20 No specific guidance on HVAC systems or strategies is provided in relation to COVID-19. |

Monopoly Rule No. 8 – Once you own all the properties of the same colour you may develop them…

Board game rules apply in Sydney CBD – a benefit to the community chest?

My first few blogs should be approved by the end of the week but in the meantime, this is public knowledge and interesting.

The City of Sydney or the Central Sydney Planning Committee is the consent authority for development other than major projects; there are currently 16 major projects (Figure 1), plus an additional 19 development control plans, dictated by area (Figure 2).

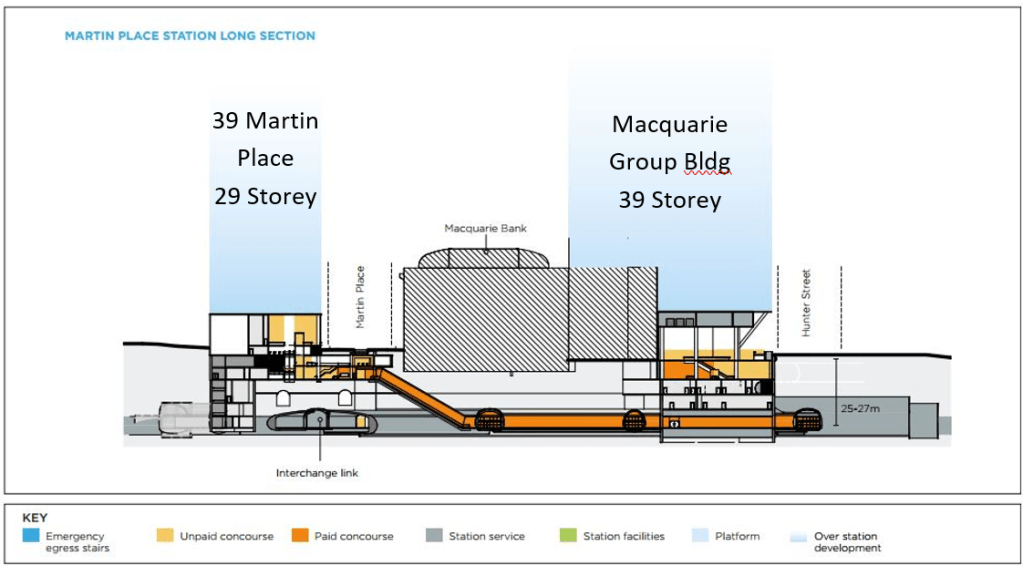

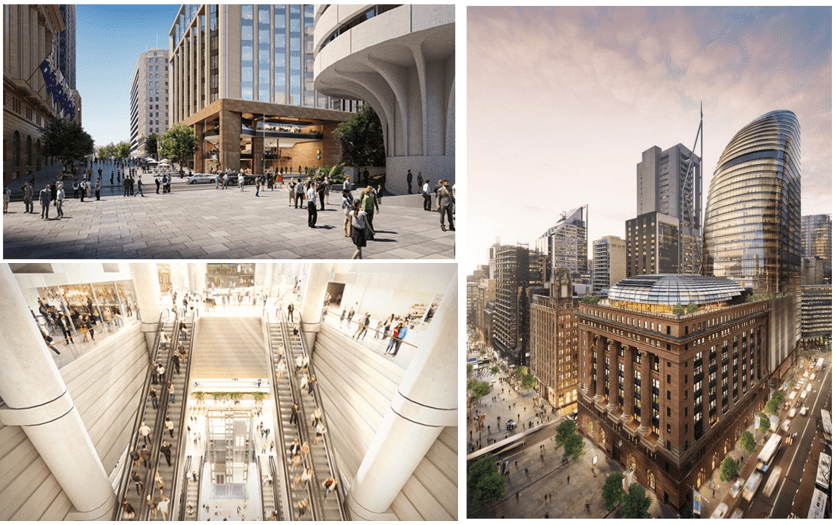

Now that you can picture the board. In square 014 is my current project, Sydney Metro Martin Place Station. Martin Place is a pedestrian mall in the middle of the CBD and has been described as the “civic heart” of the city as it is home to the Sydney General Post Office, the Seven Television Network News Centre, Cenotaph and the State Savings Bank building. As an iconic, cultural and historic area of the city planning permission is limited to 20 storeys. That is, unless, you own all the properties on the block. In which case the permitted number of storeys (and thus sqm of new office space) can be spread amongst the properties on the block.

Fig 3. Satellite image of Martin Place and the heritage bank.

Macquarie Group is a financial services provider who own the heritage listed State Savings Bank building at the Centre of Martin Place. The new metro station tunnels beneath the bank and the station entrances are currently being excavated to the North and South (Figure 3). Work on site began in January 2018. By March that year Macquarie Group submitted an unsolicited proposal to the Government of New South Wales for two Over Station Developments (OSD). The towers would be predominately commercial, with Macquarie Group occupying both. The concept for the north tower was more than 40-storeys with a podium to be integrated with the existing 50 Martin Place (bank), while the south tower was to be more than 28 storeys.

In May 2018, a site-specific amendment was made to the Sydney Local Environment Plan. The new planning provisions for the Martin Place Metro Precinct permitted a larger building envelope for the South site. The State Savings Building is only 10 storeys high yet by planning controls it could be 20. Thus, by owning all the properties on the block Macquarie Group were able to exploit a loophole and by September an agreement had been made for Macquarie to deliver the new station and two new towers by 2024, along with construction partner Lendlease. The North tower will be 39 storeys and the South will stand at 29 storeys. Transferring their available storeys (houses or hotels!) to a neighbouring property (Figure 4).

Community Chest gained $355 million as the Government sold the air rights above the new metro station. Macquarie will spend a further $637 million on the construction and delivery of the new underground Martin Place station integrated with a retail and recreational precinct, two new office towers and the existing Martin Place railway station.

Cost of the new station $378.6 million

Fee paid by Macquarie $355 million

Cost to the Taxpayer $23 million

Once the new buildings are complete in 2024, Macquarie is also likely to make another payment to the government to reflect the increased value of the land; as the world’s largest infrastructure asset manager, they should know. Macquarie now own the rights to one of the most coveted corporate addresses in Sydney. New metro trains are due to deliver thousands of customers from the suburbs straight to their new towers every four minutes. By 2056, New South Wales will have more than 12 million residents and Sydney is predicted to become a global city, similar in size to London or New York. Time will tell whether Macquarie’s investment will pay dividends, but I have a feeling owning the site of Sydney’s largest public transport hub will mean that the bank inevitably wins.

VR just a matter of clicking the right buttons?

Nothing too in-depth in terms of engineering but this article might be of interest as an overview of where current consultant thinking is with VR.

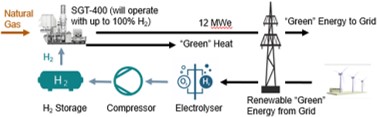

Green Hydrogen

Clean, reliable and secure energy supply is a key requirement for the further development of the European economy. At the same time, the Paris Agreement and its aim to limit the global warming to well below 2°C call for a quick and significant reduction of CO2 emissions, including the energy sector. In the energy sector this can only be achieved by a significant increase of the share of renewable energy sources (RES). As the most abundant RES, wind and solar, are intermittent by nature, there is a need for energy storage technologies, to provide back-up power when wind and solar output are low and more generally for load levelling and grid stabilisation.

Chemical storage appears to be the most promising long-term energy storage technology. Among chemical storage technologies, hydrogen is expected to dominate as it can be produced by electrolysis of water using excess energy from RES, easily compressed and stored, and finally re-electrified using gas turbines.

Siemens vision for energy

e-Hydrogen is the generation of Hydrogen through electrolysis of water.

The Role of the Gas Turbine

Siemens are currently modifying existing Small Gas Turbine Combustor technology to burn both Natural Gas and Hydrogen for fuel. These Hydrogen and Natural Gas Co-firing Gas Turbines will be able to run on any ratio mixture of Hydrogen and Natural gas, with the desired proportion being solely hydrogen. Natural Gas stores ideally would be used for redundancy or emergency purposes.

Emissions & Closed Cycle

(Civils if you’ve made it this far, cheers)

The combustion of Hydrogen in pure oxygen yields water as the only waste product, as follows:

This means theoretically the only exhaust products out of the Gas Turbine will be steam, therefore the intention is to turn the engine into what is known as a closed cycle. Whereby the exhaust steam is condensed to water, and fed back into storage for subsequent electrolysis into hydrogen and oxygen.

The reality is that combustion of Hydrogen in Air will additionally yield oxides of nitrogen – bad. This will drive development of more robust catalytic converters to strip oxides of Nitrogen out of the exhaust.

Further Reading

Concrete Repair Procedure

Sadly E&Ms this is one for the Civils but feel free to read if you want.

This week I was asked to assess a contractor’s proposed concrete repair procedure for precast concrete road barriers (similar to the central reservation barriers on the M25 or M6).

A repair procedure was required because the end stops had slipped during the pour resulting in 10-15mm excess cover at the ends of the barriers. The contractor’s proposal was to saw-cut or grind the concrete back to the design cover so the barriers met the precast dimensional tollerances. Having seen this done on phase 2 site for in-situ patch and crack repairs, I thought it was a reasonable proposal providing adequate H&S measures are employed.

After checking the project specifications for concreting and precasting I found no reason to reject their method. Prior to approving the Contractor’s RFI, a senior engineer reviewed my work and insisted that 3mm (min) of Megapoxy P1 mortar repair grout must applied to any cut or ground surfaces. He explained this is done to the ends of precast super T beams when they cut the prestress strands as 3mm of Magapoxy P1 equates to 50mm of cover.

I can understand why this is done on the super Ts however the road barriers have standard reinforcement (no strand) so is there really a need to apply Megapoxy in this case? I challenged the decision on the basis that it may not be required as that the original design cover would be maintained. In my view the Megapoxy P1 requirement is a potentially unnecessary cost (time and money) to the contractor. I was told if the contractor doesn’t like it they will let us know…

Does anyone have any previous experience of this? Is this another case of ‘this is what we’ve always done’ or is there another good reason to apply a layer of repair mortar?

It’s the simple things that can kill you

One of the labourers on my site is lucky to be alive. A few of weeks ago he was removing a star picket (think 2-foot picket) from the ground by hitting it from side to side with a sledgehammer. One of the blows resulted in a 1.5m (reportedly) spark coming out the top of the picket. The labourer was unharmed thanks only to the insulated handle of the sledgehammer and his safety boots.

They were removing formwork from a pram ramp which they had built the day before and had no idea there was an 11kV cable underneath them. The investigation has identified a significant number of lessons, but I feel it all came down to attitude.

- The contractors doing the work were complacent and not engaged with the risk management process.

- The foreman had cut corners by getting a labourer to brief the contractors and had not properly read the permit to excavate.

- The engineer wasn’t engaged with the work and had provided a permit to excavate which was hard to read.

- The senior project engineer who had signed off the permit to excavate hadn’t done their due diligence when reviewing it.

All of this was because they had the attitude that the activity was low risk.

Perhaps the most interesting point is that this is the 14th service strike they have had on this job and they hit a 132kV cable on their last one with an excavator. The lessons identified from that are pretty much the same as this one…

This is what we always do…

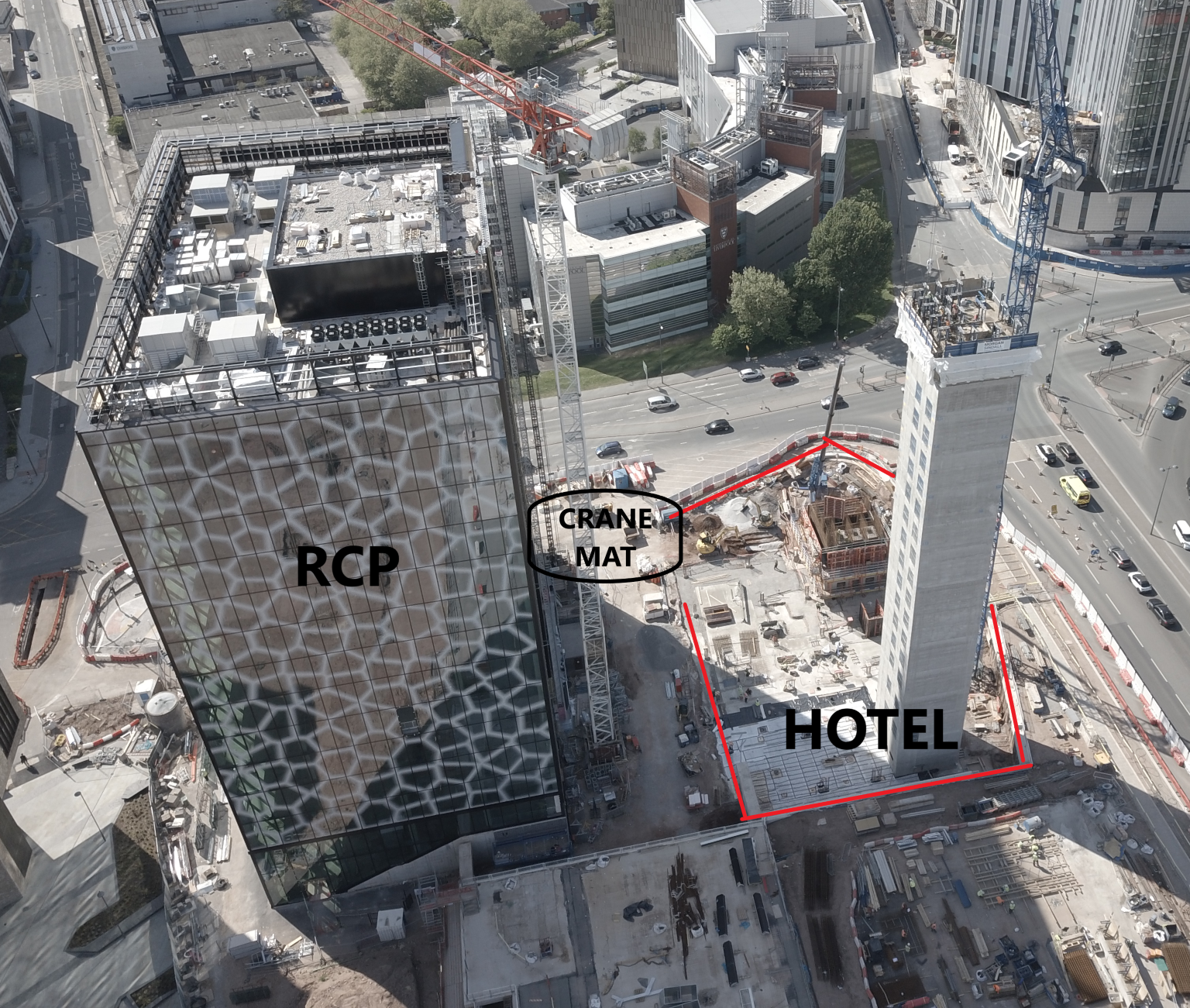

I’m working on the construction of a 17 storey concrete framed hotel for Liverpool City Council. The project is part of a wider scheme of redevelopment that has 10 plots being redeveloped in close proximity. The plot adjacent to my project is a 14 storey concrete framed office building which will be the Northern Headquarters for the Royal College of Physicians (RCP).

The RCP project has reached the stage where its tower crane can be dismantled. As part of this plan a 500t mobile crane will be brought in to lift off the tower crane jib. The only place the mobile crane can set up is across the main access gate to both my project and RCP. This will cause significant disruption for at least the 2 days required for the lifts. In addition to this, 2 days has been allocated to the construction of a 300mm thick crane mat using 120m3 of 6F1.

The ground conditions across the scheme are sandstone bedrock and the area where the crane will set up is a 150mm thick reinforced concrete slab. When questioned if the crane mat was necessary the response wasn’t completely convincing. It seems that a crane mat has previously been used on this scheme and so a consultant has been tasked to design the mat.

With the prospect of an additional 2 days of delay to my project and the associated Compensation Event claim, it was agreed that plate bearing tests could be carried out to confirm if the crane mat was required. Unsurprisingly, the concrete slab on top of sandstone bedrock proved to be a sufficient base for the crane outriggers. As such, my project has saved 2 days of delay, £14k of overheads for our concrete frame subcontractor, 120m3 of 6F1 and the cost of employing a groundwork’s subcontractor to complete the crane mat. Not too bad for 1hr of testing at a cost of a few hundred quid!

In many ways senior management are ruthless with commercial aspects of the project and exploiting savings and Compensation Event claims. On the other hand, I have been surprised at how unwilling people are to challenge the way we do things on site or question what information the decision was based upon.

Has anybody else been surprised at how unwilling people are to challenge the way things are done?