Who has the force?

I am currently designing a turning dolphin for a tideway project in the Boston Barrier area. The dolphin will consist of steel tubular piles driven into the river bed with a 2m deep RC pile cap. The cap will have a bollard fixed for mooring ships. The dolphin will also require fendering.

Fendering forces (for those that don’t know) are calculated from the berthing energy being dissipated over distance and time. This means that you can only calculate a “fendering force” once the fender has been chosen.

The problem has arisen when deciding the forces on the dolphin. It is BAM Nuttall’s opinion that we should be provided with the forces to expect from mooring and fendering and design a structure to resist those forces. The client has paid for a navsim analysis of the shipping externally and they have provided a line force (fendering) and point load (mooring) for the structure with a caveat that these numbers should be used to validate our own and not be used as a design value. These simulations and calculations were executed with assumed fendering choices and are therefore not really worth the paper they’re written on.

The elephant in the room is nobody thinks it’s their responsibility to provide the fendering solution and nobody wants to stick their neck out and offer up a design value. In our eyes this is a dispute between the client and HR Wallingford but we are caught in the middle. If the client isn’t paying Wallingford to provide us with these forces then why are they paying them? When BAM bid for the design, they did not include the cost of calculating these forces into our quote. This means if we are stuck with having to do it we will need to subcontract this out (as we do not hold the specialty within the department) and will not be able to recover the cost.

As I have no view of the contracts between each party I am simply an outside observer speculating on what disputes may arise from this project. I thought it was an interesting question to ask though about where design responsibility for determining forces lies. Of course we would assume responsibility for calculating wind forces on a hoarding so why not fendering on a dolphin?

I happen to work for a consultancy that specialises in just this….

If you have to do it, why would you have to contract it out? Its is relatively simple. BAM may not want to undertake it because of the perceived complexity. If I can do it, it’s not hard.

The issue here is have you priced for it? Either way you’ll have to pay for it, or the client will depending on the scope of the contract.

The process:

You need to go back to basics and look at the vessels will moor using the dolphin? The client should provide the vessel particulars or failing that a type of vessel, typical lengths and displacements, with which you can use ship tables to work out typical values.

When provided with this the berthing energies can be easily calculated using BS 6349-4. From there you can select a bollard type type and then subsequently the deck and pile sizes. Fendering can easily be selected from catalogues, such as the Trellevorg catalogue.

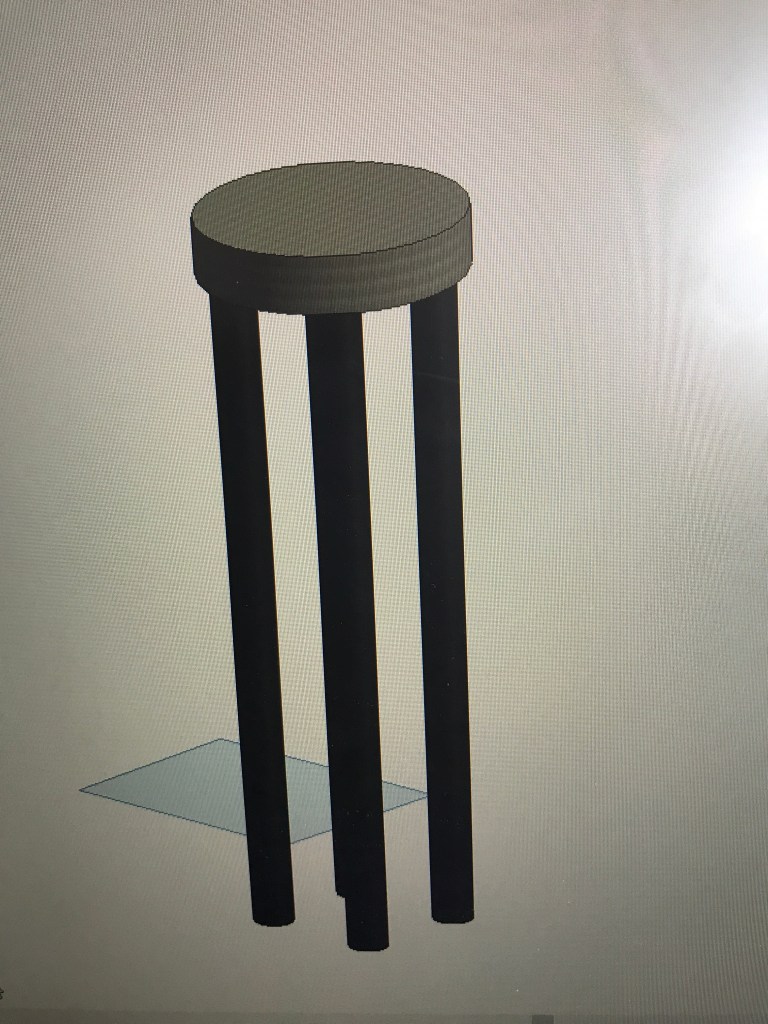

I’d question the fundamental design at the moment, without knowing the full details.

How is this dolphin going to suitably prevent movement of the vessel? Normally you require multiple mooring points, at the very least, moorings fore and aft to stop lateral movement and depending on the ship spring line moorings are likely to be required to prevent lateral movements. See BS 6349-1 for typical arrangements.

A singular dolphin like this would only really be of use of you don’t mind the vessel rotating around depending on the wind direction, for example if this was located in the middle of an estuary. If that’s the case, I’d then suggest a floating mooring. Have a look at an admiralty mooring which uses chains and anchors driven into the riverbed, this will prove a lot cheaper.

Seems weird looking at this in isolation, a mooring analysis should be undertaken but there may be other factors you haven’t mentioned for brevity in the post.

Cheers Jon, I have done that exact process and calculated a berthing energy. The point i was trying to make was nobody feels comfortable taking design liability because it is considered specialist. I’m sure BAM would rather pay you boys a few quid rather than risk this thing failing. That attitude might change if we haven’t priced for it and they’re looking to save some money. I look forward to the upcoming CPD available in those BS if it does land on my desk. Expect phone calls!

🙂