Archive

It’s the simple things that can kill you

One of the labourers on my site is lucky to be alive. A few of weeks ago he was removing a star picket (think 2-foot picket) from the ground by hitting it from side to side with a sledgehammer. One of the blows resulted in a 1.5m (reportedly) spark coming out the top of the picket. The labourer was unharmed thanks only to the insulated handle of the sledgehammer and his safety boots.

They were removing formwork from a pram ramp which they had built the day before and had no idea there was an 11kV cable underneath them. The investigation has identified a significant number of lessons, but I feel it all came down to attitude.

- The contractors doing the work were complacent and not engaged with the risk management process.

- The foreman had cut corners by getting a labourer to brief the contractors and had not properly read the permit to excavate.

- The engineer wasn’t engaged with the work and had provided a permit to excavate which was hard to read.

- The senior project engineer who had signed off the permit to excavate hadn’t done their due diligence when reviewing it.

All of this was because they had the attitude that the activity was low risk.

Perhaps the most interesting point is that this is the 14th service strike they have had on this job and they hit a 132kV cable on their last one with an excavator. The lessons identified from that are pretty much the same as this one…

This is what we always do…

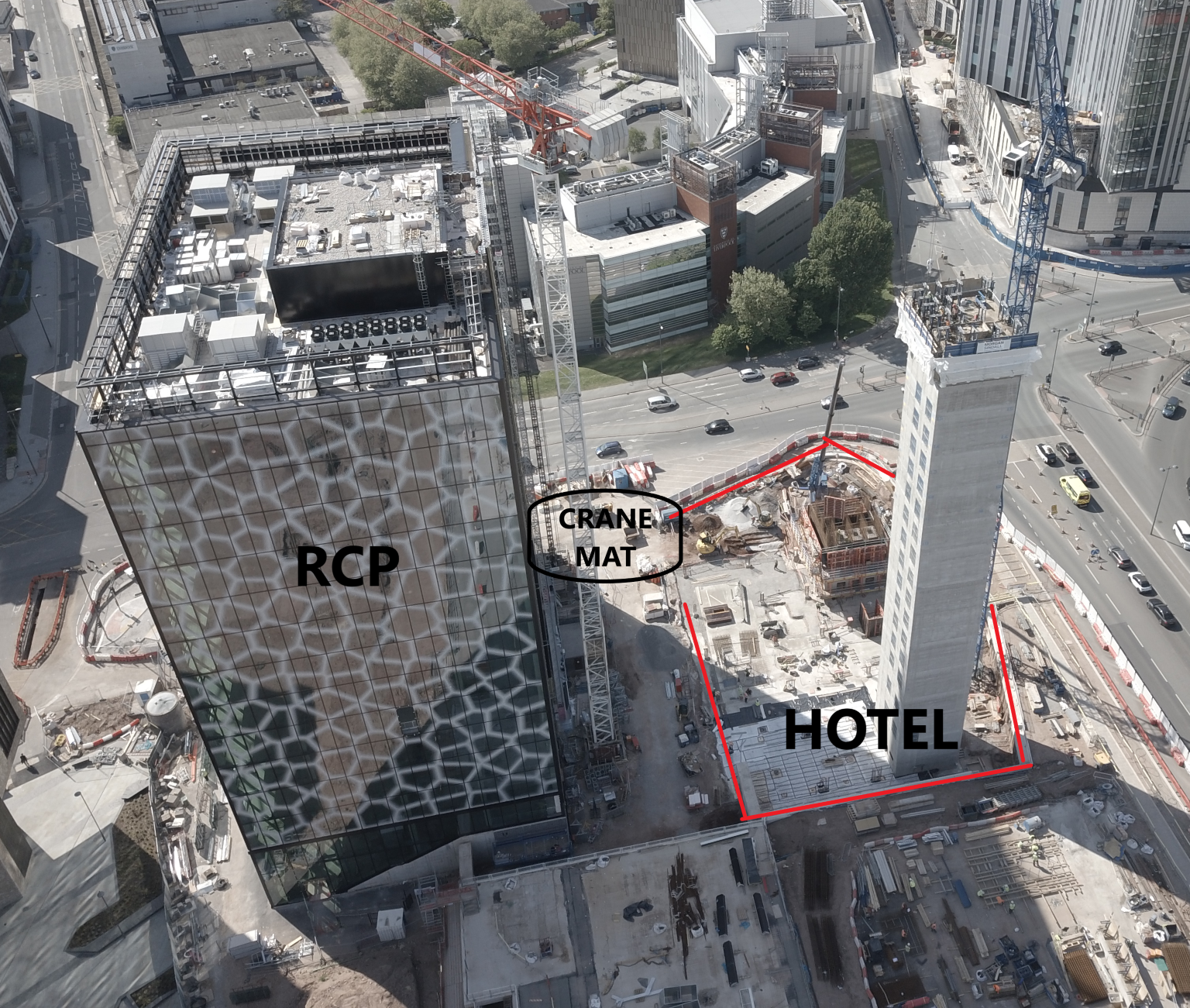

I’m working on the construction of a 17 storey concrete framed hotel for Liverpool City Council. The project is part of a wider scheme of redevelopment that has 10 plots being redeveloped in close proximity. The plot adjacent to my project is a 14 storey concrete framed office building which will be the Northern Headquarters for the Royal College of Physicians (RCP).

The RCP project has reached the stage where its tower crane can be dismantled. As part of this plan a 500t mobile crane will be brought in to lift off the tower crane jib. The only place the mobile crane can set up is across the main access gate to both my project and RCP. This will cause significant disruption for at least the 2 days required for the lifts. In addition to this, 2 days has been allocated to the construction of a 300mm thick crane mat using 120m3 of 6F1.

The ground conditions across the scheme are sandstone bedrock and the area where the crane will set up is a 150mm thick reinforced concrete slab. When questioned if the crane mat was necessary the response wasn’t completely convincing. It seems that a crane mat has previously been used on this scheme and so a consultant has been tasked to design the mat.

With the prospect of an additional 2 days of delay to my project and the associated Compensation Event claim, it was agreed that plate bearing tests could be carried out to confirm if the crane mat was required. Unsurprisingly, the concrete slab on top of sandstone bedrock proved to be a sufficient base for the crane outriggers. As such, my project has saved 2 days of delay, £14k of overheads for our concrete frame subcontractor, 120m3 of 6F1 and the cost of employing a groundwork’s subcontractor to complete the crane mat. Not too bad for 1hr of testing at a cost of a few hundred quid!

In many ways senior management are ruthless with commercial aspects of the project and exploiting savings and Compensation Event claims. On the other hand, I have been surprised at how unwilling people are to challenge the way we do things on site or question what information the decision was based upon.

Has anybody else been surprised at how unwilling people are to challenge the way things are done?