Archive

Who has the force?

I am currently designing a turning dolphin for a tideway project in the Boston Barrier area. The dolphin will consist of steel tubular piles driven into the river bed with a 2m deep RC pile cap. The cap will have a bollard fixed for mooring ships. The dolphin will also require fendering.

Fendering forces (for those that don’t know) are calculated from the berthing energy being dissipated over distance and time. This means that you can only calculate a “fendering force” once the fender has been chosen.

The problem has arisen when deciding the forces on the dolphin. It is BAM Nuttall’s opinion that we should be provided with the forces to expect from mooring and fendering and design a structure to resist those forces. The client has paid for a navsim analysis of the shipping externally and they have provided a line force (fendering) and point load (mooring) for the structure with a caveat that these numbers should be used to validate our own and not be used as a design value. These simulations and calculations were executed with assumed fendering choices and are therefore not really worth the paper they’re written on.

The elephant in the room is nobody thinks it’s their responsibility to provide the fendering solution and nobody wants to stick their neck out and offer up a design value. In our eyes this is a dispute between the client and HR Wallingford but we are caught in the middle. If the client isn’t paying Wallingford to provide us with these forces then why are they paying them? When BAM bid for the design, they did not include the cost of calculating these forces into our quote. This means if we are stuck with having to do it we will need to subcontract this out (as we do not hold the specialty within the department) and will not be able to recover the cost.

As I have no view of the contracts between each party I am simply an outside observer speculating on what disputes may arise from this project. I thought it was an interesting question to ask though about where design responsibility for determining forces lies. Of course we would assume responsibility for calculating wind forces on a hoarding so why not fendering on a dolphin?

The importance of a naming convention and change control.

I am currently working for John Holland on the upgrade of the Bruce highway between Edmonton and Gordonvale.

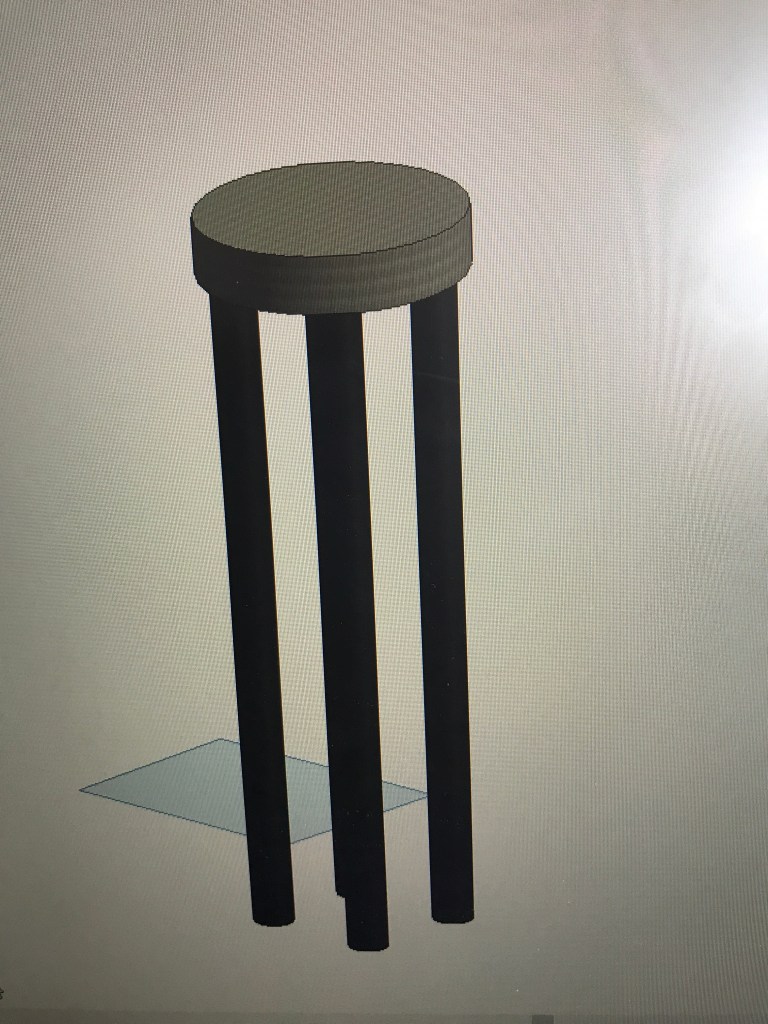

The project is currently still in the design phase. One of the tasks I have been involved in so far is conducting a take-off from the Prelim Design drawings to compare this data to the estimates at tender. There are significant differences but identifying them has been more challenging than it should be. Chainages are often a standard point of reference on a road job so how hard could it be? What is the chainage of the top culvert in this picture? What is the chainage of the bottom culvert?

Hint: There are 3x different chainages shown on this drawing.

I know there were mixed views on PMQ but in my mind this is a perfect example of where configuration management and change control would be useful. If every culvert was given a name/number it would save time trying to second guess which chainage different teams had used to refer to which culvert. As it stands the drawings, schedule and programme on this particular project are not as joined up as they should be.