Polystyrene Formwork

Some pent up blogs to follow now that I have permission from the project office to blog. * DISCLAIMER. The contents of this blog have been made available to the author for academic purpose and are not to be disclosed other than for academic use.

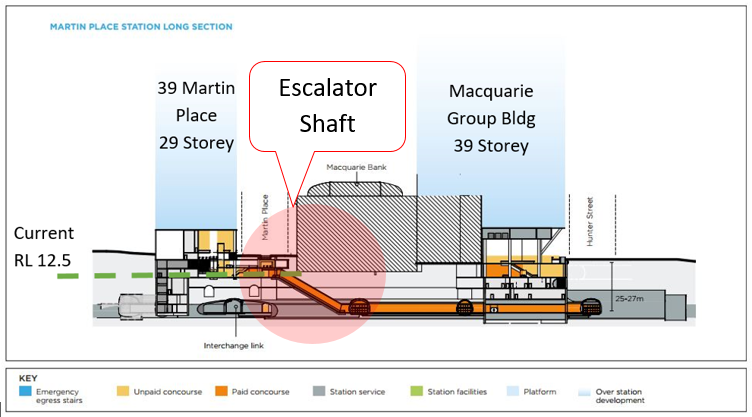

The Martin Place Metro Station site has two deep excavations either side of Macquarie Bank, a heritage building (Australia’s equivalent of the Bank of England and looks a bit like Gringots!). As per my last blog, the North Site has since been purchased by the bank, as has the over station development rights for the South Site. Long and short of it we have tunnelled beneath an important historic landmark and now need to excavate a diagonal escalator shaft from -10m below the front door, back underneath the bank and into the station cavern below. Best not to crack any of the marble…

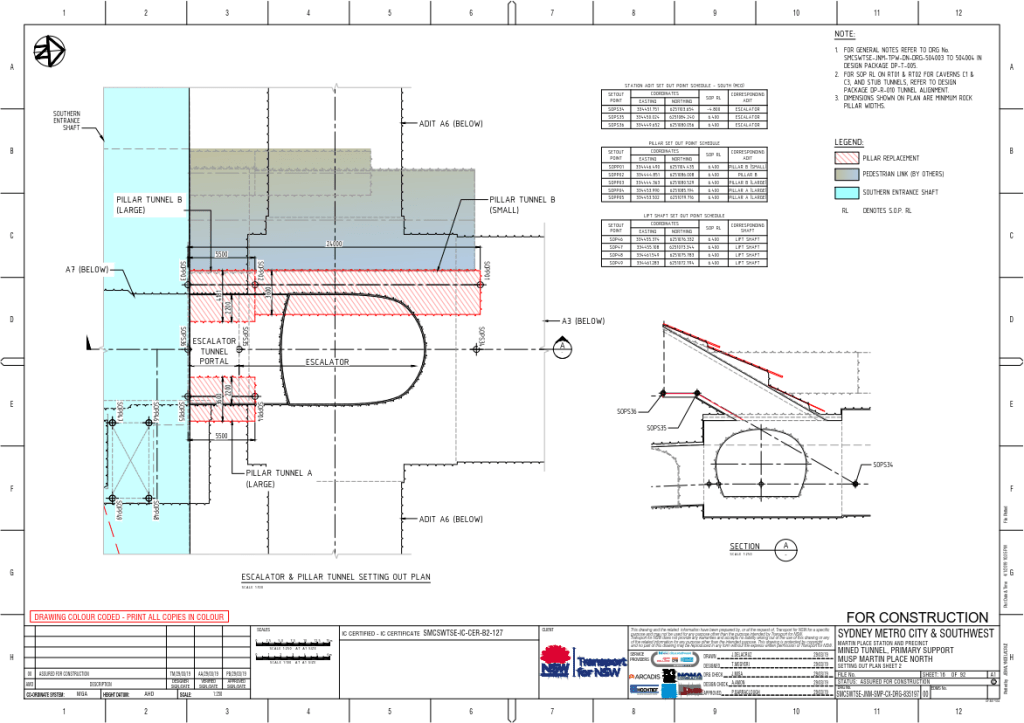

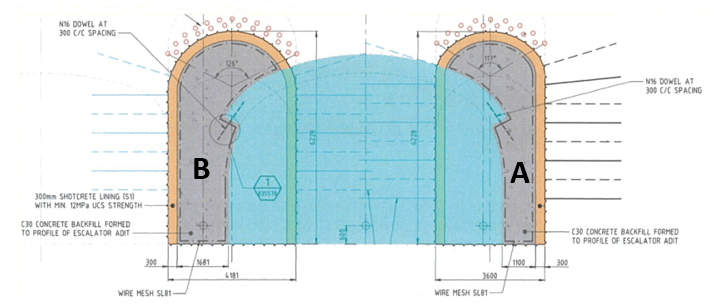

To sure up the Hawkesbury Sandstone rock beneath the bank and prevent settlement the designer has proposed three large reinforced concrete pillars be installed beneath the bank. Pillars A and B have been installed since I have been on site. The requirement for Pillar C is yet to be determined based on monitoring the bank buildings response. Pillar C could be constructed in the future by the follow on contractor, Lendlease when they start the tunnel and station fit out contract early 2021.

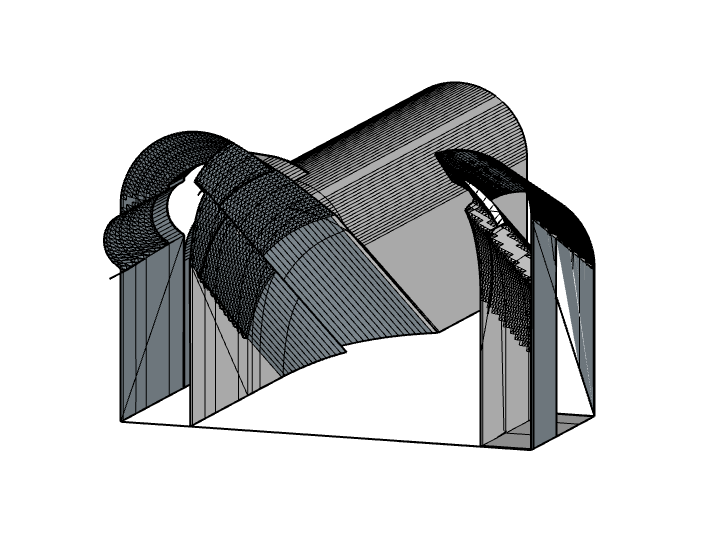

The profile of the escalator tunnel is constant as the portal descends. At the tunnel opening and throughout the descent there is a portion to be excavated which overlaps with the pillar tunnels leading to a challenging shape. Approximately half of each pillar tunnel will overlap the escalator tunnel portal. The notches at either side are critical for the installation of lattice girders, providing temporary support as fresh rock is cut, prior to temporary support (lattice and shotcrete) and the final reinforced concrete lining. A derivative of the New Austrian Tunneling Method. The challenge was how to create such a complex shape.

1. Change the design;

- Alter the profile of the escalator tunnel crown so that it is consistent for the whole profile

- Change the profile of the lattice girder support of the escalator tunnel crown and where they sit on the side walls.

These ideas were briefly explored by the senior site engineer however the time it would have taken to push through the RFI process and redesign would have caused delays. We have had to accept the challenging shape and come up with a temporary works design solution for the formwork.

2. Change the method;

- Pour half of the pillar with the notch space created by formwork

- Pour half of the pillar and fill in the notch or block it out

- Pour the whole tunnel with reinforcement through half and create a block out notch within the pour

The Formwork, Reo, Pour (FRP) Senior Engineer and Shaft Senior Engineers did a quick appraisal and cost for each scheme. We have a very experienced concrete subcontractor on site (Kenny’s) and they also could not find a cost effective formwork. In the end we opted for the whole pillar pour with a block out.

3. Selection of materials for a block out;

- High Density Cardboard had been used as a block out elsewhere on site earlier in the project – needless to say it didn’t work as cardboard is porous it turned to mush and did not prevent the ingress of cement and leave the desired shape.

- Wood creates a splinter hazard when hammered out and could have caused shrink/swell issues with moisture. It was also relatively heavy to manoeuvre into position within the tight reinforcement cage. The weight of wood also made it difficult to create an internal supporting structure within the form. It was have been hard to form a seal between sections of wood too.

- Polystyrene. Create a custom shape blockout to fill the entire void within the form. Light weight, easy to work with, can be purchased to exact size and dimensions.

The polystyrene block out worked really well however the choice to pour the entire cross section of the pillar caused a one week delay to the programme during excavation as the 50MPa concrete was difficult to break out. Two unforeseen secondary effects also occurred. Excavation in sandstone generates a lot of silica dust and water suppression is vital. Pumps operate daily to remove the slurry and water from the blinding slab. Broken segments of polystyrene and the tiny balls within it subsequently blocked and damaged two pumps and polystyrene still litters the site nearly two months since it was dug out. Secondly, the spoil disposal subcontractor picked up on the polystyrene content of waste leaving site. Virgin excavated natural material (just the rock) costs $29/tonne. General Solid Waste Recyclable costs $115/tonne. For the rest of the 320m3 (7680 tonne) of excavation the spoil was often reclassified as GSWR. Not all loads were deemed GSWR but those that were costed the site an additional $15,000. Perhaps the complex formwork would have been cheaper after all.

Polystyrene for formwork is genius!

I assume by the photos that this is what they are using. I do have some questions though.

1. Noting that a single crack can produce many little polystyrene balls that are hard enough to manage in my living room, how do they manage disposing of the formworks?

2. Is the polystyrene backed with thin plyboard (or something) to aid rigidity?

3. Is the formwork able to be reused, or are they considered single use?

This is sacraficial formwork and the trick used to be to disolve it with petrol. Sadly pouring petrol onto sites tends not to meet environmental and safety constraints these days. Hydrocarbon contamination is minmal after it evapourates but don’t light a match in the tunnel…

I have to observe it is a pretty basic shape so I think not using timber was a lazy option.