Archive

On the bus, off the bus, repeat.

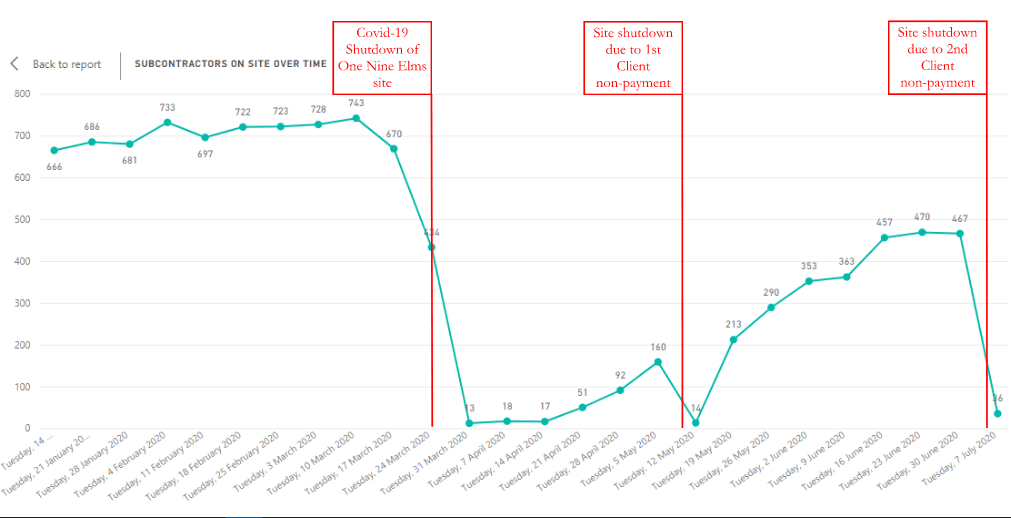

Prior to Covid-19 hitting the UK, the One Nine Elms (ONE) site in London was operating at 600-650 operatives each day. Running two jump forms, pre-stressed slabs, facade installation, large raft slab pours, demolition, blockwork the site was in full swing.

When Boris announced that we all must stay at home, Multiplex (Principal Contractor) assessed the situation and took the decision to shut the site until such time as mitigation measures had been put in place to make the site as safe as possible. Significant time was spent re-configuring the canteen and welfare areas to allow social distancing rules to be adhered to. When site opened back up on 20 April, it was running at 50-70 operatives for the first week with phased increases in subcontractor numbers on site to safely manage the new measures.

A mere three weeks after returning to site, Multiplex took the decision to cease works, this time due to non-payment by the client – the monthly valuation was priced at just shy of £13m. Thankfully this closure was short lived as the client paid up after only 2 working days lost on site.

Fast forward to now. Last Monday 29 June, notice was issued to all subcontractors and consultants of our intention to suspend works due to non-payment of the client, come Sunday night no payment had been made, resulting in a cessation of works on site at COP Monday 6 July.

Speculation within the project team has been made as to the cause of the non-payments. Some think that this is part of a strategy by the Chinese client (R&F Properties), I think this unlikely as these stoppages are likely to cause delays to the programme and, in the form of loss and expense claims from subcontractors, significant excess costs. The delays to the programme are only exacerbated by subcontractors being unable to mobilise operatives quickly following the recommencement of works. Numerous subcontractors have already warned of delays of up to six weeks before they would be able to achieve full strength on site.

My estimation is that, more worryingly, R&F are facing significant cash flow issues. R&F owns four development schemes in London valued at £4.5bn, of which One Nine Elms is likely to top out at £1bn. With these significant costs and with delayed payments becoming a worrying trend, it will be “interesting” to see how this situation plays out. With the number of projects in the UK and Australia backed by Chinese investors I’m curious if anyone else has faced any issues recently, or if I’m just the lucky one?

Long term lessons learnt?

Yesterday during the Comdt’s backbriefs the issue of lessons identified/learned was raised. This prompted me to finally write the blog post I planned to write a while ago and never got round to completing but with different conclusions.

The apartment I’ve been renting in Melbourne has 14 storeys above ground and a 2-storey basement. As far as I can establish, the building was around in 1996 so is at least 24 years old but could be older (internet research is currently drawing a blank).

Why is this important? Yesterday we discussed whether we are failing to truly identify and learn our successes or failures immediately after an event. Generally, the consensus was that we are bad at ‘learning lessons’. If we fail to do this in the short term, I suggest we are even worse at identifying our successes or failures further down the line… say 24 years later.

Our car parking spaces are on basement level 2 so approximately 6-8m below ground level. Following rainy weather, there is always water on the floor of the basement (Melbourne’s climate is similar to the UK so there’s a fair bit of rain). The water appears to enter the basement around the service penetrations (ventilation ducts) and through construction joints in the diaphragm walls and at the wall-column interface. I’ve taken a few pictures to show what I mean.

(Note the water penetration is from the vent ducting at the top of the picture and not the pipe.)

Why is this an issue? Well for me and the other residents our stuff gets wet. This is annoying but can be worked around. The bigger issue is structural durability because the ingress of water can increase the reinforcement corrosion rate and could lead to early failure of the wall. At the service penetrations and column-wall interface, there is likely to be sufficient cover to protect the reinforcement however at the mid-height wall construction joints there won’t be. I’ll hedge my bets that the contractor didn’t apply an additional protective coating to the rebar at this location meaning the reinforcement will corrode quicker.

So here are my thoughts on reviewing the construction/design issue 24 years later:

- Why were construction joints used at mid-height?

- Could the pour height have been increased so the basement walls were poured in one go? If not (due to concrete drop height or safety issues) could additional reinforcement be provided at the construction joint or a protective system employed to mitigate against corrosion?

- Was the ventilation service penetration part of the original design or was it added at a later stage?

- Was the sealant around the ventilation penetration fit for purpose and was it installed correctly?

- Has the sealant’s design life been exceeded and not replaced? Is poor building maintenance an issue here?

- Have any of these issues been highlighted to the Designer/Contractor to influence their future decisions/works? I suspect not.

My consultant does a lot of inspection of old bridges for asset owners which allows them to identify issues with historical designs that can be adapted or mitigated in their current designs, hopefully avoiding similar issues in the future. I’m not sure if the same exists in the vertical construction space but a feedback loop from building condition surveys to designers would be one way to improve future designs. I admit I don’t have the answers but hopefully, this post will spark some further discussion.

FPE Basics

I stumbled across this at work today. It’s an article published in The Singapore Engineer in April 2018 and is written by engineers who work in one of SMEC’s sister companies.

The article covers Singaporean legislation requiring buildings to be protected to prevent terrorist attacks. From what I remember of the FPE Level 1 training on RETCC and subsequent insights at 170 Engr Gp it also covers the basic FPE assessment process and principles.

I thought I’d share for two reasons:

1. As basic revision prior to the Phase 4 FPE Level 2 training.

2. So we can compare UK military practice to the civilian consultant approach. At this stage, I suspect they are very similar.

Protecting Infrastructure Against Terrorist Attacks – Surbana J (sorry for the poor quality of the images but a pdf print copy was the best I could manage).