Archive

Too simple a process to get wrong, right?

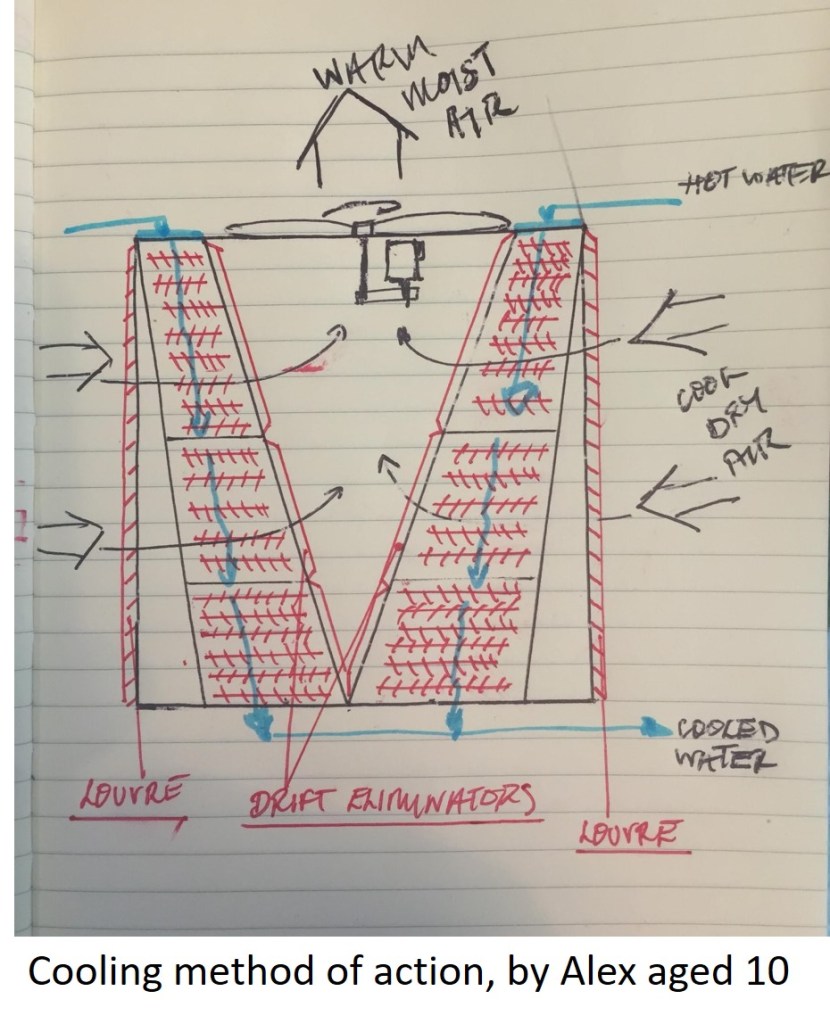

Terminal 5 at Heathrow is served locally by a set of open-loop cooling towers that are on the roof of the Terminal 5 Energy Centre, where heat can be dumped following coolth being provided to the terminal building. The operation of open loop cooling towers is wonderfully simple. The method employs latent cooling by passing the hot water, as a product of the cooling process, through a distributor (think sprinkler set) over ‘fill’ material (think plastic lattice material) that is designed to cause disruption to the flow path and encourage droplet formation. Concurrently, a cross-flow of air is forced through the fill by the presence of a whacking great fan mounted on the top.

Amongst the many design controls that exist are intake louvres (on the visible outside face of the tower) and drift eliminators (on the internal face of the fill material). The job of both of these is largely to prevent as far as possible the escape of water droplets from the fill material both into the leaving air stream and also the surrounding area. Escaping water causes problems including; legionella risk, increase make-up water needed (some is always lost in the leaving air stream) and increased scaling of all components.

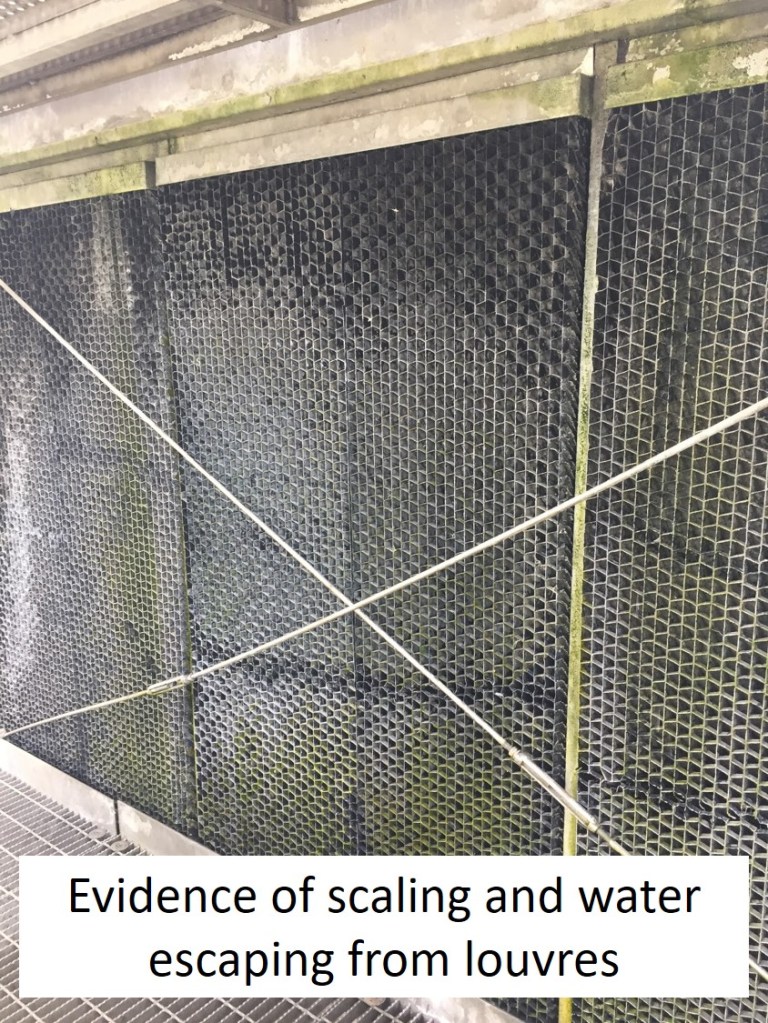

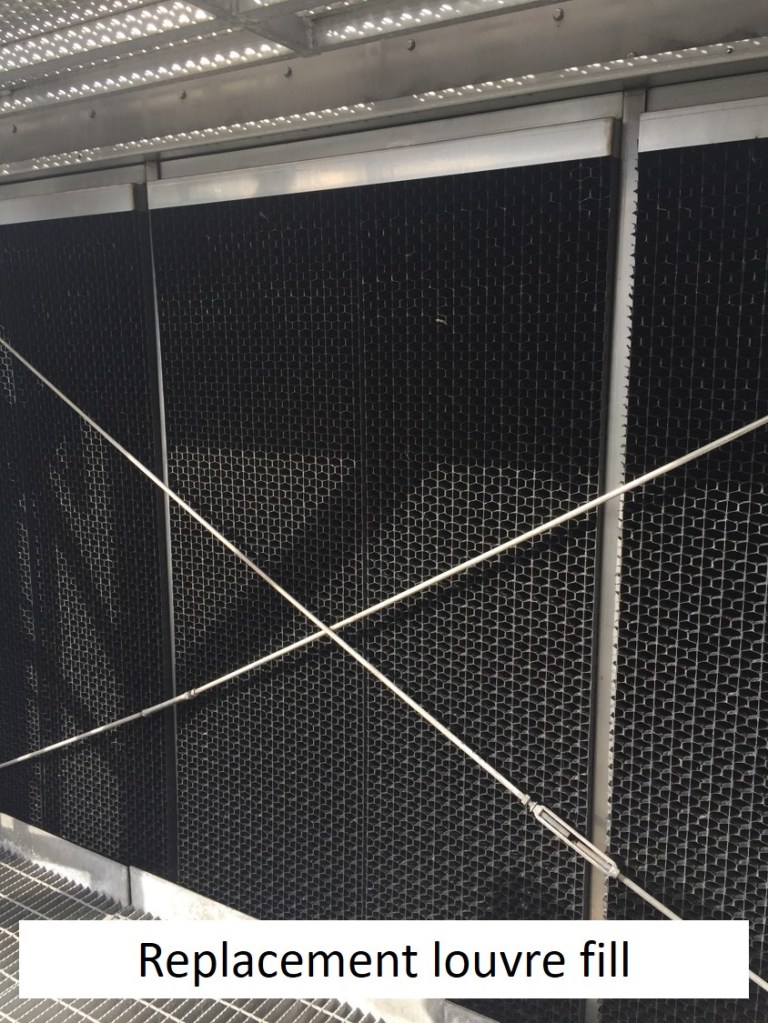

Inspections last year of the T5 cooling towers by the HSE revealed all of the above issues and an improvement notice was issued. Long story short, the louvres and drift eliminators had been installed upside down (think a cheese grater the incorrect way up) so were effectively continually funnelling water out of the cooling tower at a fairly alarming rate (discovered once accurate measuring of the make-up water had been carried out). For a simple installation error that occurred in the past the renovation process now involves the replacement of fill material (albeit due to a separate issue of incorrect de-scaling regime), replacement louvres and eliminators and in some cases replacement of belts, pulleys and fan drive-shafts (where the budget can accommodate) as a result of scaling and corrosion. Not bad for mis-reading the ‘This side up‘ label.

Low flying aircraft

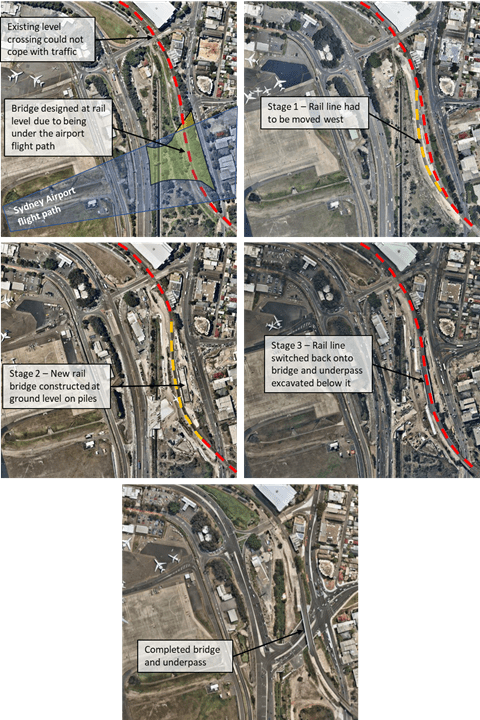

Part of my project’s scope is covering the defects from John Holland’s previous project next to Sydney Airport. The liability period ends next month so Transport for New South Wales (the client) are pushing a few through before time runs out.

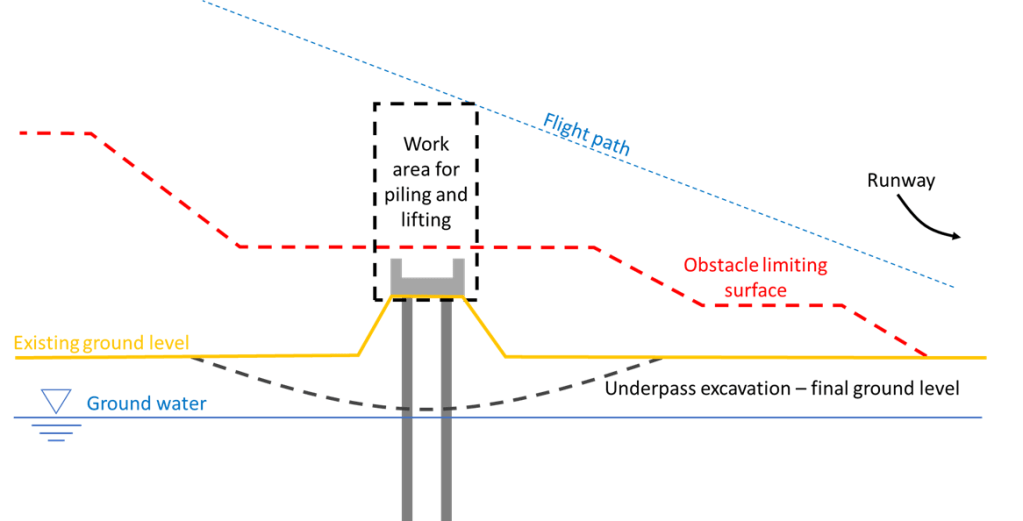

An element of this project was constructing a railway bridge in the airport’s flight path. I have included a few photos from the project to show the staging design and significant construction restrictions.

If this was being done now it would be much easier… I rarely see any aircraft.

Contractors are a delight

If I may be so bold as to interrupt Claire’s blog very briefly, I’m having a couple of issues with BP’s principal contractor and I’m keen to gauge the opinion of those out there in the PET ether.

Bit of background:

For the overwhelming majority of projects, repairs and construction activities, BP does not have a competitive tendering process. Instead, all work is given to the chosen Engineering, Procurement and Construction (EPC) contractor, Wood Group. Wood have a 5 year contract to be the EPC contractor of choice, an agreement which is due to expire in 2021.

The contract runs on a cost reimbursement basis. This is common practice throughout the oil and gas industry.

The issue:

My question is this:

If a contractor comes up with a project execution plan (PEP) that is not fit for purpose due to their misinterpretation of an SoR, should BP be liable to pay for the costs incurred when reworking the plan?

One of the projects I’m working on at the moment is a modification to the cooling medium system on board Glen Lyon FPSO. To alleviate cavitation in a bypass valve caused by excessive pressure in the system, it is proposed that the system operation be modified so that one out of three (1oo3) pumps is operational at any one time, rather than 2.

This proposal was successfully modelled by Genesis, the BP front end engineering and design (FEED) contractor. Within the SoR, there was a requirement for Wood Group to validate this modelling by way of a live off-shore trial. The main requirements for the trial broadly consisted of:

- Ensuring there was enough cooling duty to meet system requirements, when running 1oo3 pumps.

2. Ensuring flow induced vibration (FIV) was at tolerable levels within the suction and discharge pipework of the operational pump.

3. Adjusting the temperature set-points for the system working fluid.

When I say “misinterpretation” above I was being generous. In Wood Group’s PEP, they had not made provision for adjusting the temperature set points within their trial procedure. This was stated clearly within the SoR and, if that in itself wasn’t exacerbating enough, Wood Group representatives were also present (and paid handsomely for the privilege) throughout the FEED stages of the project and were fully aware of the option generation and selection!

Upon reading their PEP, I immediately flagged this omission and asked them to come back to me with an amendment to their trial procedure, to include the set point adjustment.

Their cost estimate was adjusted accordingly. Whilst the inclusion of the set point adjustment within the trial procedure is an acceptable reason for an up-arrow in costs, I was surprised to find that they had also charged “management fees” for the reworking of the PEP and the accompanying estimate.

To my mind, it feels wrong that they are seeking reimbursement for rectifying what was unquestionably a mistake of their own making.

In lieu of having access to the full terms and conditions of the contract, I sought counsel from my line manager who advised that whilst their charges are not in the spirit of good partnership, I should authorise the “management fees” in the interests of not causing unnecessary delays to the project. BP’s design philosophy, generally speaking, is almost always driven by time constraints and schedule deconfliction, my cynical view is that Wood Group are very wise to this fact and will look for opportunities to exploit it to benefit their bottom line. With no competition when it comes to the awarding of work for BP, it could be argued that Wood Group fully has BP over a barrel.

It seems to me that BP is stuck between a rock and a hard place. It would be wholly impractical to tender for all projects and modifications in the North Sea (my asset alone has over 30 ongoing projects) but by signing up to a fixed term EPC contract with a single supplier, they are opening themselves up to exploitation, especially when operating under cost reimbursement terms. Whilst in this instance the “management fees” amounted to a little over £1000, these incidents are not one offs; extrapolated across the entire North Sea portfolio, the overall cost to the business is likely to be significant.

Interested to hear your thoughts, and whether you’ve had any similar experience.

Super Tunnel

Al, I will raise your UK’s busiest airport series with Australia’s biggest infrastructure project. No starring role for me but tonight (Wednesday) my site at Martin Place gets some good coverage. I have recently been cross bracing and propping the temporary pedestrian bridge they install as we are now excavating underneath it.

https://www.sbs.com.au/ondemand/program/sydneys-super-tunnel

Might need a VPN to get it to work in the UK but there are a few clips on YouTube as well.

D’ya like dags?

Before all the E&Ms get carried away blogging lets talk about concrete.

Well, the answer if you are an Irish concrete pump operator is no. Despite the Archimedes screw inside a mixer truck a small amount of concrete always remains inside, especially in drum mixers. You can wash the truck out, run water through the drum while it rotates and even pressure-wash the inside. But some concrete residue is always left. And it dries. The next trip a little more is left. And it dries. Over time, this becomes a problem, reducing the volume of the mixer and its capacity.

The process is expedited when a concrete mixer truck driver does not wash out the machine properly between loads and aggregate and chunks of concrete are left to cure in the drum. Once hardened, and a new batch is being spun in the machine at full tilt, the old lumps of concrete can work loose and get fed into your 47m concrete boom pump at 1am. A dag as it turns out is a lump of old, hardened concrete. Pondering this new technical term and having had a quick google, turns out it is defined as ‘a lock of wool matted with dung hanging from the hindquarters of a sheep’.

The pump struggled as it passed through the hopper – we dropped the hopper but the problem persisted. Not knowing how large the ‘dag’ was and hoping it would break up in the line the operator continued pumping concrete only for it to block the 5” to 4” reducer pipe at the bottom of the boom. We retracted the boom, removed the reducer and found the dag! Weighing about 3kg and full of 30mm aggregate – we were pouring a 10mm mix.

The ‘dag’ delayed the pour by an hour. As a site engineer you control the batching times of concrete from the plant and arrival to site. I had to return a near full load (7m3) truck to the batching plant as it got too old for us to use (over two hours). Hot, dry, stiff concrete won’t pump either. Touch the side of the mixer truck and you can feel how old the concrete is. The pump operator will always try and add water, even to a fresh batch, but as a quick rule of thumb – for every 2cm of slump you gain it will reduce the 28 day strength by 3-4 MPa. Mercifully the next load came swiftly and with a lot of needle and form vibrating we avoided forming a cold joint in the pour.

Our concrete supplier have a really handy guide for ordering pre mixed concrete which I would recommend a quick read. Doesn’t mention dags though…