Archive

Think twice before paying for an ‘expert opinion’

This is just a short post but I thought it was interesting.

Whilst researching into UXOs and the effectiveness of qualitative vs quantitive risk assessments I came across an interesting study. In the study the researchers asked 25 experts in the UXO industry to make a series of risk assessments, typically based on the probability of a UXO detonating in certain scenarios (e.g. striking a UXO with the back hoe of an excavator or being played with by children).

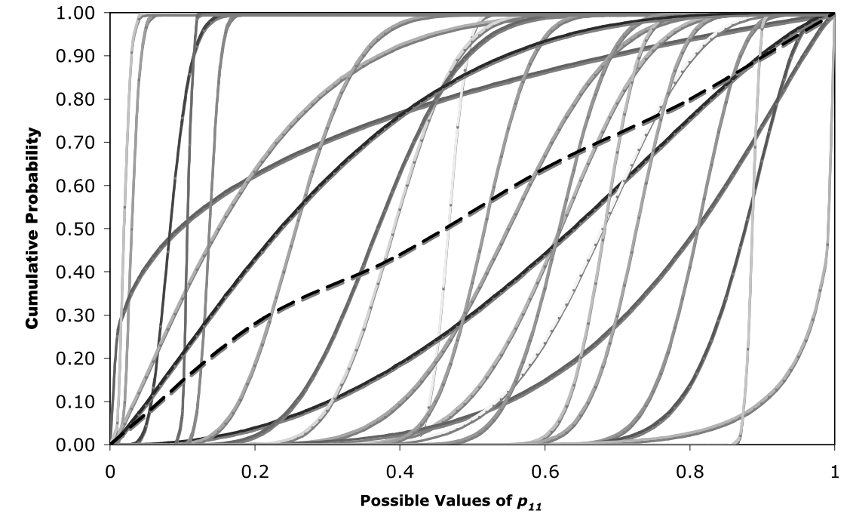

The study essentially concluded that when you pay an expert for their opinion, at least in this field, you might as well not bother. The figure below shows the results of part of the study where each fitted cumulative distribution function (CDF) represents the assessed probability of a UXO detonating by a different expert. The report summarises that “In three of the six scenarios, the divergence was so great that the average of all the expert probability distributions was statistically indistinguishable from a uniform (0, 1) distribution—suggesting that the sum of expert opinion provides no information at all about the explosion risk.”. This basically means that the average of their results said the probability of explosion was equally likely to be 0% as it was 100% (with a low confidence interval), not necessarily very useful information! My initial thoughts are that where data can be acquired, assessments should be made quantitively where possible.

The solid curves are the CDFs of the individual experts, and the dashed curve represents the CDF of the mean explosion probabilities estimated by the experts. The horizontal axis indicates the probability of explosion. The vertical axis represents the cumulative probability that the chance of explosion is less than or equal to the corresponding horizontal axis value.

The full report can be accessed here: https://onlinelibrary.wiley.com/doi/abs/10.1111/j.1539-6924.2008.01068.x

Piling in

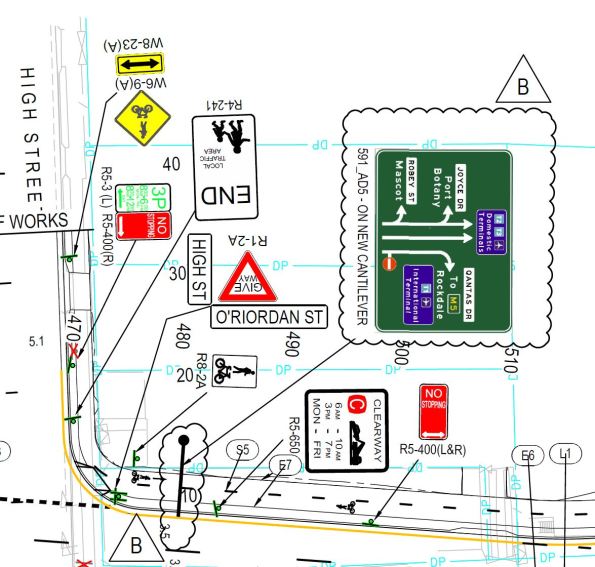

My project is a road widening in Sydney that requires a number of road signs. There are a significant number of small signs and three large ones which require piles. A number of sub-contractors tendered for elements of the work earlier this year but only one submitted a tender which included both the signs and piles. This was the deciding factor in the decision and the contract was awarded to them for approx. $500k.

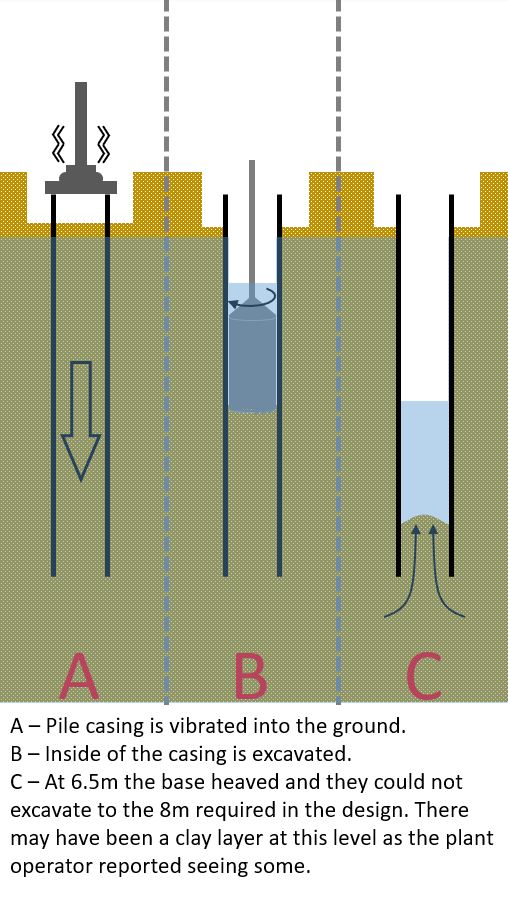

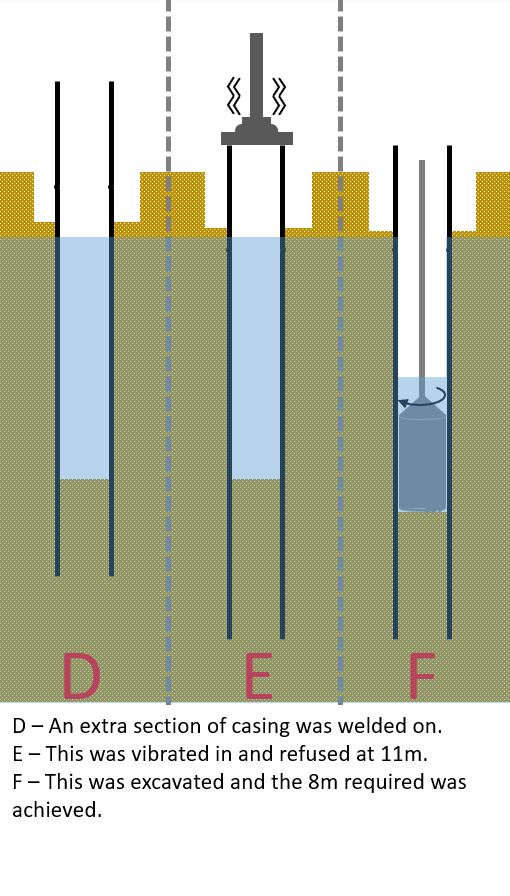

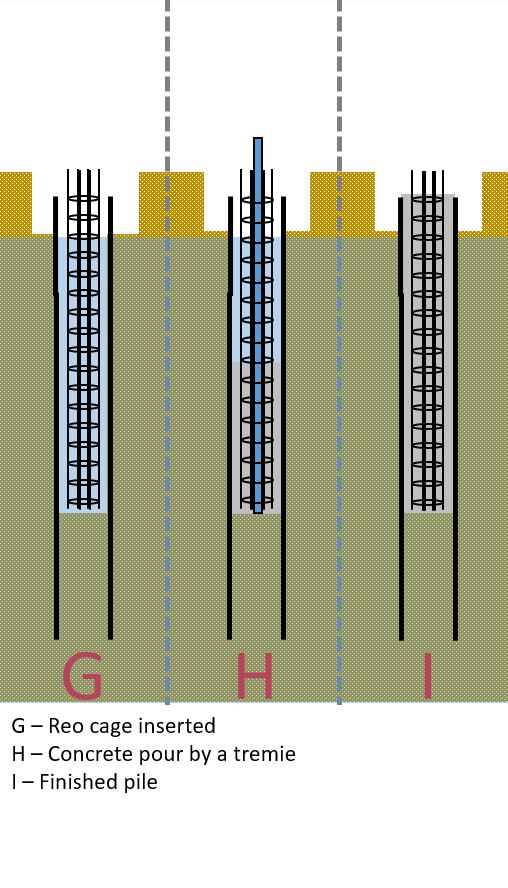

The sub-contractor selected is a sign structures specialist and they sub-contracted the piling work. As there are only a small number of piles they decided against CFA piles and instead opted to use a permanent casing, bore the piles and use a tremie to pour the concrete. The rational for this, I believe, was that the savings made in plant mobilisation outweighed the cost of the lost casing. The ground is medium to dense sand with a couple of clay layers with ground water a couple of meters below ground level.

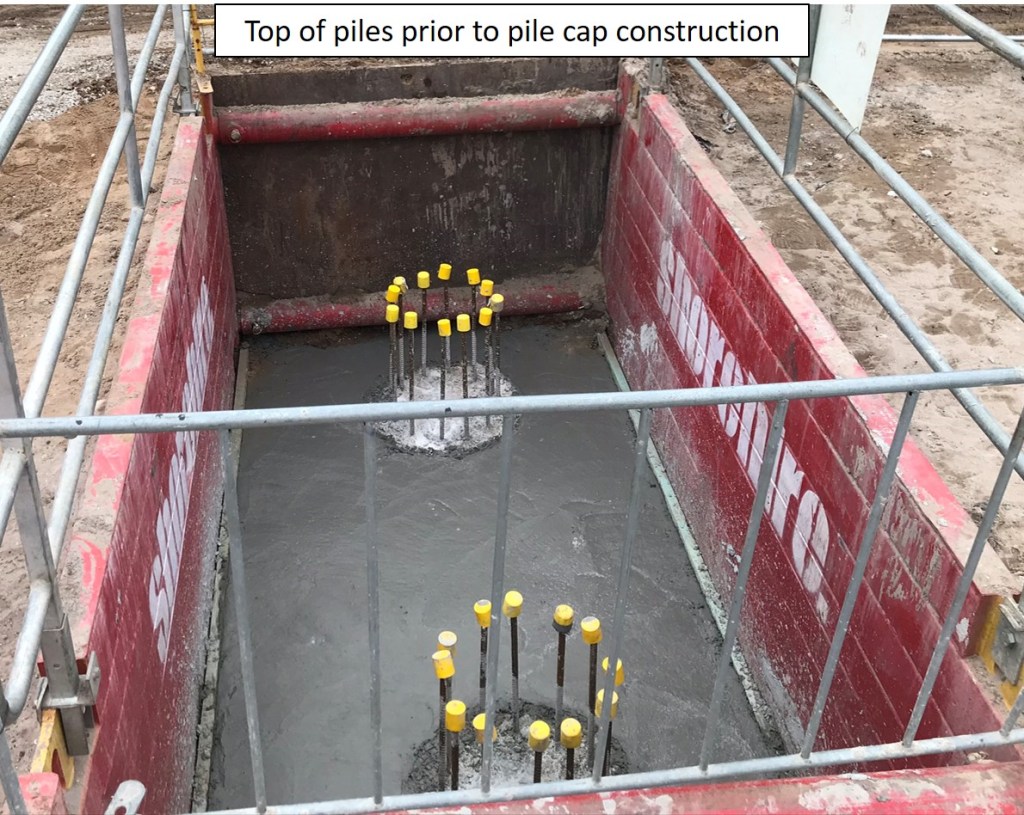

When piling for one of the signs (shown in the photo) the sub-contractor was unable to excavate to the design depth. What happened and photos are shown below:

When the first excavation could not reach the depth required the sub-contractor claimed it was unknown ground conditions and wanted to put in a claim. Looking at the contract they had taken on this risk. However, as these signs are on the critical path and John Holland wants to complete this job as quickly as possible the sub-contractor was instructed to proceed. Discussing this with the contracts manager his take is that John Holland will probably end up paying some of the extra costs as they are very small ($3-5k) in relation to delay costs to the project.

We (John Holland) ended up having to supervise all the piling works as the sub-contractor was unable to. Most of these costs were back charged to the sub-contractor. The general feeling in the project team is that if they were to do this again a specialist piling company would have been selected.

I estimate that the horizontal loads on these piles area around 4 times larger than the vertical loads. What has been built in my opinion is significantly over engineered as:

- The pile casings are now 35% deeper.

- The ground conditions are far more favourable than the medium dense sand allowed for in the design.

I feel that when the pile could not be excavated to the design depth there may have been an opportunity to get a revised design approved with a deeper pile casing and shallower concrete infill. However, the focus is on constructing as per the client’s design and getting this design approved would have taken far longer than just getting the sub-contractor to continue and project delays costs were far more significant.