Piling in

My project is a road widening in Sydney that requires a number of road signs. There are a significant number of small signs and three large ones which require piles. A number of sub-contractors tendered for elements of the work earlier this year but only one submitted a tender which included both the signs and piles. This was the deciding factor in the decision and the contract was awarded to them for approx. $500k.

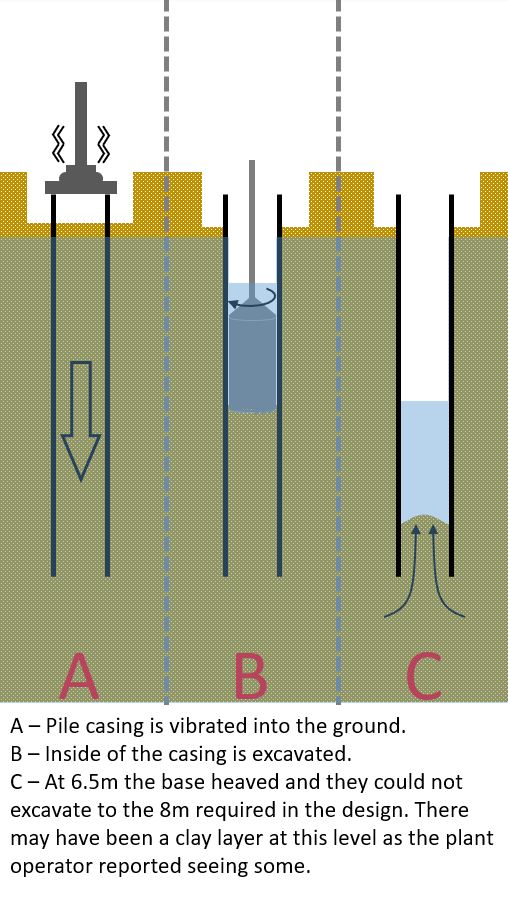

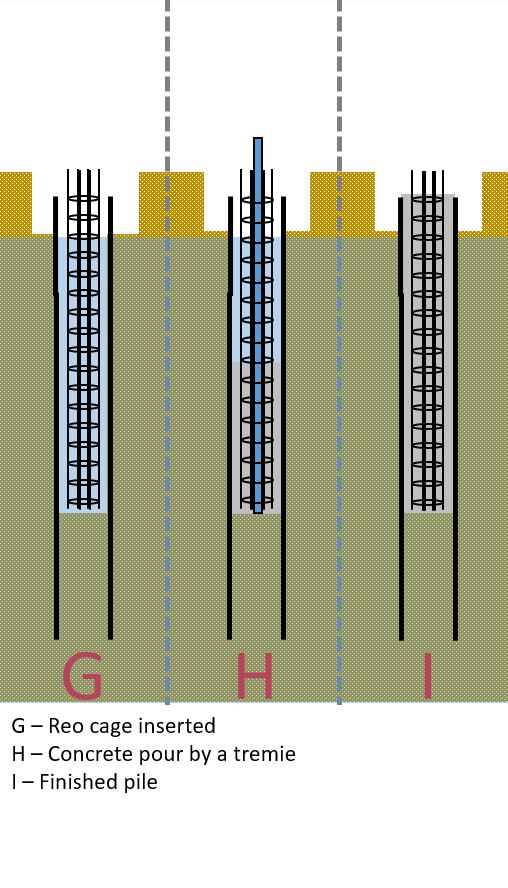

The sub-contractor selected is a sign structures specialist and they sub-contracted the piling work. As there are only a small number of piles they decided against CFA piles and instead opted to use a permanent casing, bore the piles and use a tremie to pour the concrete. The rational for this, I believe, was that the savings made in plant mobilisation outweighed the cost of the lost casing. The ground is medium to dense sand with a couple of clay layers with ground water a couple of meters below ground level.

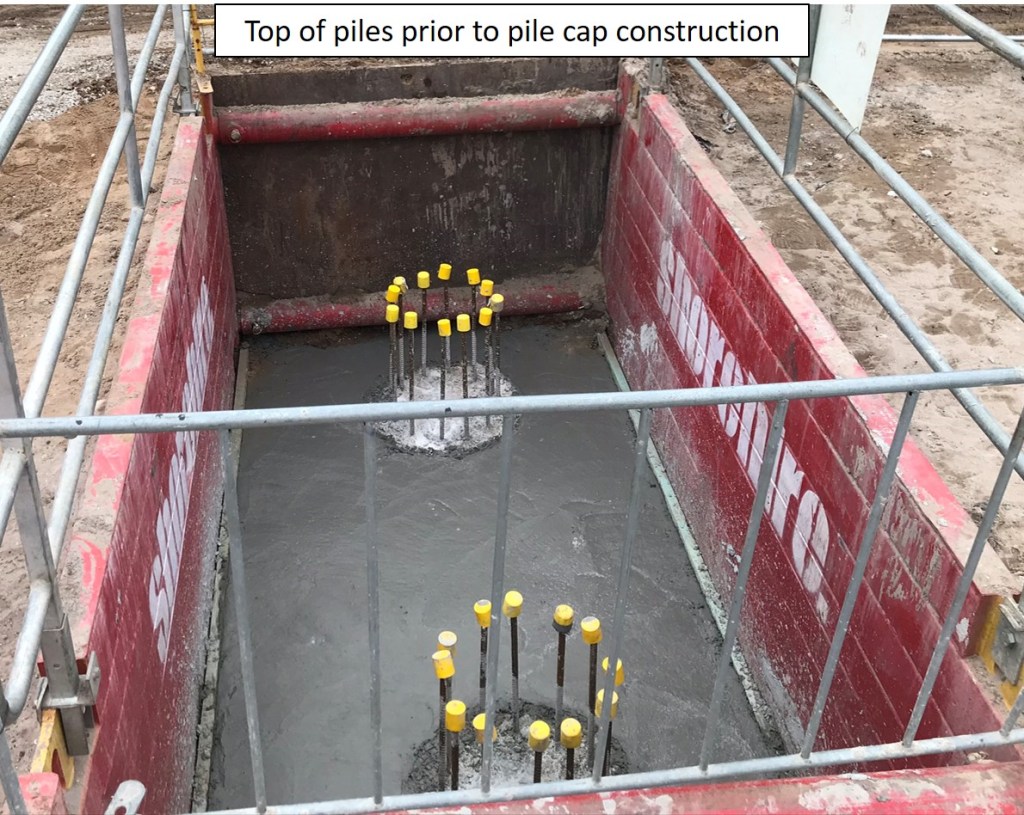

When piling for one of the signs (shown in the photo) the sub-contractor was unable to excavate to the design depth. What happened and photos are shown below:

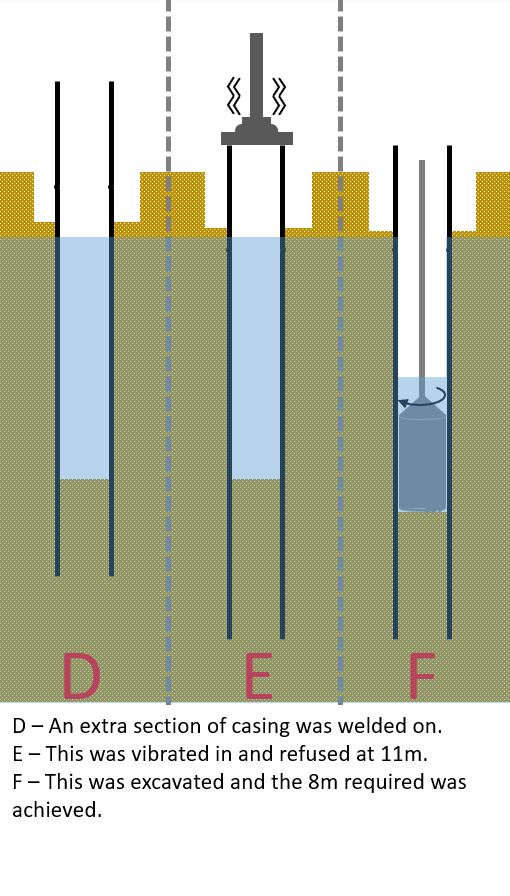

When the first excavation could not reach the depth required the sub-contractor claimed it was unknown ground conditions and wanted to put in a claim. Looking at the contract they had taken on this risk. However, as these signs are on the critical path and John Holland wants to complete this job as quickly as possible the sub-contractor was instructed to proceed. Discussing this with the contracts manager his take is that John Holland will probably end up paying some of the extra costs as they are very small ($3-5k) in relation to delay costs to the project.

We (John Holland) ended up having to supervise all the piling works as the sub-contractor was unable to. Most of these costs were back charged to the sub-contractor. The general feeling in the project team is that if they were to do this again a specialist piling company would have been selected.

I estimate that the horizontal loads on these piles area around 4 times larger than the vertical loads. What has been built in my opinion is significantly over engineered as:

- The pile casings are now 35% deeper.

- The ground conditions are far more favourable than the medium dense sand allowed for in the design.

I feel that when the pile could not be excavated to the design depth there may have been an opportunity to get a revised design approved with a deeper pile casing and shallower concrete infill. However, the focus is on constructing as per the client’s design and getting this design approved would have taken far longer than just getting the sub-contractor to continue and project delays costs were far more significant.

Hi Rupert, that’s interesting. Were there any other solutions considered? I suppose if you already had the plant on site perhaps this one does make the most sense but I wonder if there was any consideration into the use of de-watering to reduce the base heave or a check with the designers as to whether 6.5m would be permissible (perhaps with re-design or a third central pile?).

Dewatering has been used on site but it would have cost more and crucially taken longer. At this stage of our job hitting the target for project competition was key. Ordering an extra few meters of the casing was the cheapest and fastest option.

Not pushing the design review was down to time and knowing that the sub-contractor held the risk. I think it probably cost them around $20k extra. They put in a claim for some of this and John Holland could have argued it was all their cost but agreed to some of it. This was mainly to maintain the relationship as their works were the remaining critical path for the project.

The sub-contractors did not have any presence actually on site and had engaged a sub-contractor for the piling which was one guy who had sub-contracted plant operators and a welder working for him. This meant that in reality the work was supervised by the John Holland supervisor.

They did try filling the casing with water after the base heaved to try and reduce the pressure differential but this didn’t make any difference.