Archive

My piles

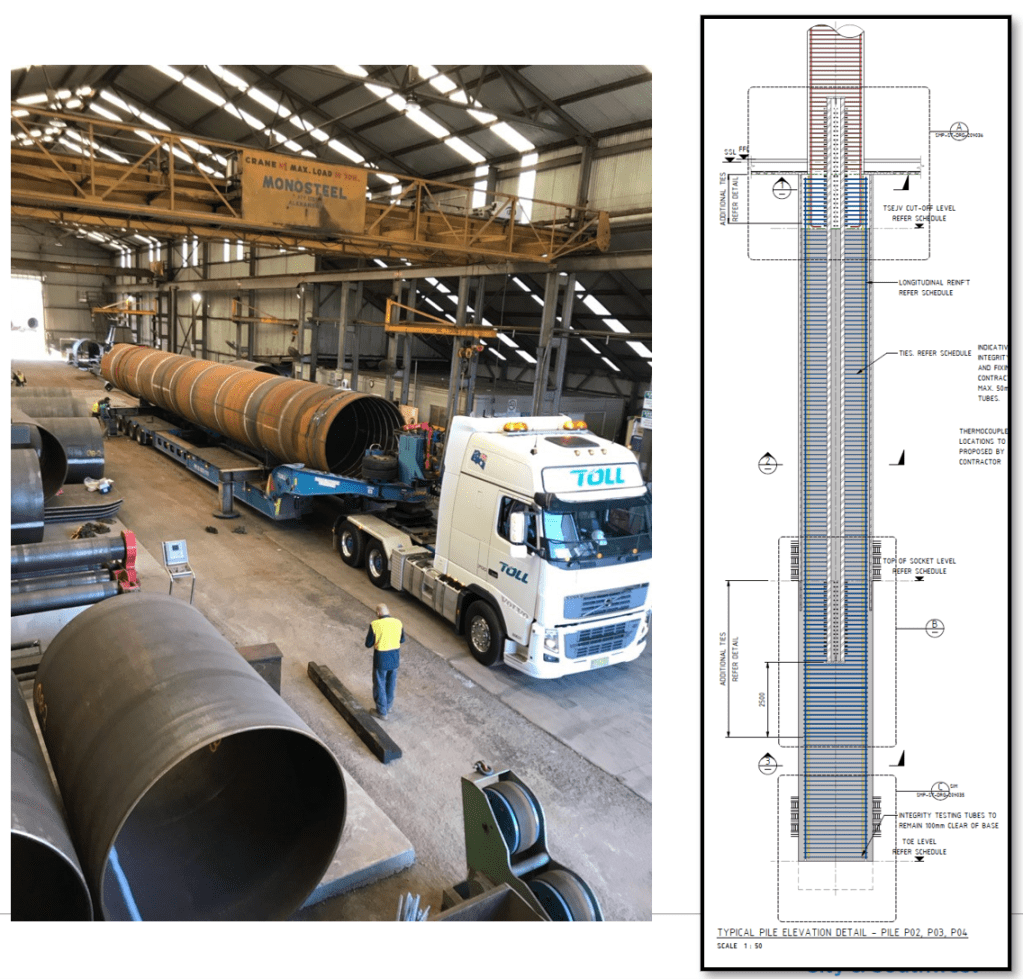

The Tunneling and Station Excavation contract at Martin Place includes the construction of 14 steel reinforced concrete piles. Each pile has a steel sleeve (max 24.1m – approx. 56t) and then a 50mm wide void to the surrounding rock for seismic loading. Three of the piles have a steel plunge column (max 29.6m long – approx. 40t) and the rest have a steel reinforcement cage installed in 3-4 spliced sections. 60MPa concrete was poured in each column using a tremie pipe.

The piles were cored using a BG40 Piling Rig and installed in 2019 prior to my arrival in Sydney however I have been in charge of trimming and ‘finishing’ the piles ready for handover to the follow on contractor this month. My scope of works and assessment of the drawings raised two terms I was unfamiliar with: CSL and TIP. 5 piles were tested for CSL and TIP and I now need to grout the CSL tubes…what are they?

Thermal Integrity Profiling (TIP)

What. A non-destructive testing method to evaluate the integrity of concrete foundations.

How.

- Place sacrificial thermal monitors along the full length of the pile, attached to the longitudinal steel reinforcement.

- Connect wire to data loggers at the top of the pile.

- Start logging prior to the concrete pour and measure the heat generated either throughout the cement hydration process or at a set time prior to the expected peak curing temperature.

- Compare the predicted and observed thermal profile.

Why. Quality assurance to prove the quality of both a piles cross-section and entire length. Deviations from the expected thermal profile indicate defects. Cool areas, shortage of concrete, i.e. necking or inclusions. Warmer areas, excess concrete, i.e. bulging and over pour. Analysis of the thermal profile can also assess if the reinforcing cage is properly aligned and centered. TIP testing is usually complete with 72 hours of a pile being cast and is the first test that can indicate in issue with a pile.

*Note, do not google TIP for piles, you end up on an NHS self-help page.

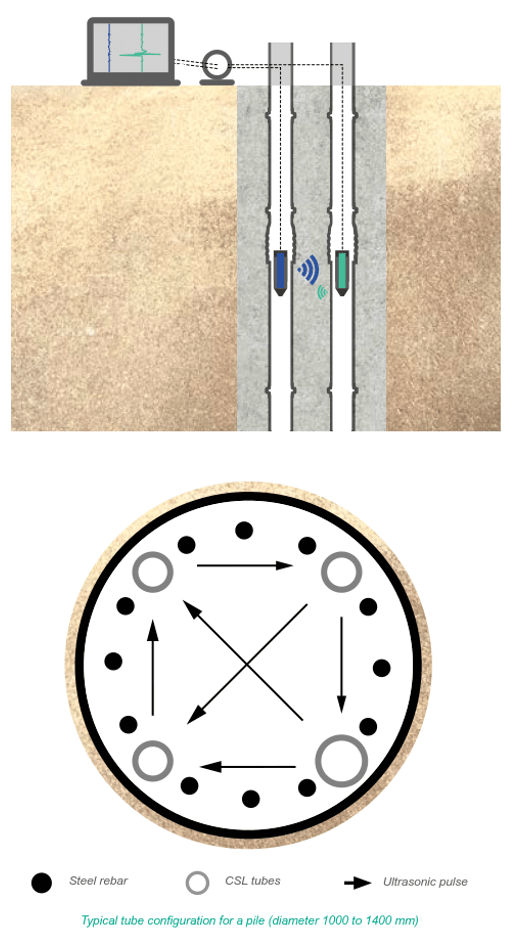

Cross Hole Sonic Logging (CSL)

What. A non destructive test method to test for the structural integrity of a pile. Sound concrete is only checked inside of the steel reinforcement cage and not the concrete cover. Also known as cross hole acoustic testing.

How.

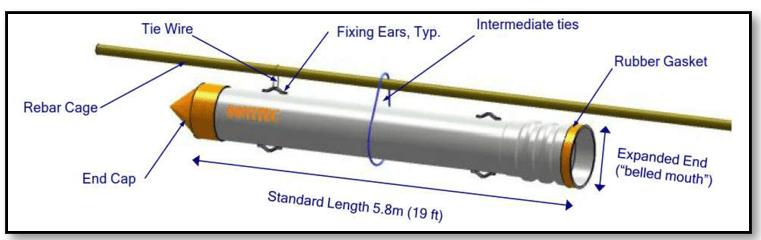

- Steel access tubes are installed inside the fabricated steel reo cage. In this instance every 300mm around the diameter. Check straightness, end caps installed, intermediate sections secured, bottom and top caps fitted. (Often CSL tubes are prefabricated by the cage supplier).

- Post installation, tubes will be filled with water.

- Post concreting, tubes will be checked for any blockage and this will be carried out by lowering weighted tape.

- Piles will be tested after 3 or 7 days post concreting and before 28days.

-Sound source lowered into a tube.

-Sensor lowered into the opposite tube to the same depth.

-Sonic pulse emitted. Relative energy, waveform and differential time are recorded, and logged.

-Procedure is repeated at regular intervals throughout the pile and then mapped. - Combination of graphs compared to identify flaws in the concrete.

- Once testing is complete and piles accepted by designers, the tubes will be grouted with 65MPa grout.

So there we go. Now I knew the purpose of the wires and tubes sticking out of the top of the pile I was looking at!

Due to access and programme a number of the piles had not been finished at the time of installation. Half had been covered up under steel plates across site for over 6 months and now needed to be dug out, 2m of sacrificial poor concrete hammered out and then have the remaining reo tied prior to inspection and sign off from the designer and IC. A few photos below of the fun that entailed and some points for discussion.

- Who conducts the TIP and CSL testing? Ours was done by the piling subcontractor, Bauer.

- Has anyone used the proper brush gaskets to maintain a clear void? For some reason despite being part of the initial planning we ended up using pool noodles!

- H&S for the subcontractor hammering inside the pile. We had to use a tripod and harness for emergency evacuation. Monitoring of live edges and enforced pairs working with a spotter at the top of the pile.

- The pile shall be trimmed to a specified cut off level leaving only sound, well compacted concrete on the surface of the pile head (as per the ITP). ‘Sound concrete’ at the pile trim level was determined by visual inspection of adequate aggregate and a few hits with a hammer to check none cracked away. This appears to me rather informal as opposed to a qualitative physical approach such as Schmidt Hammer?

CDM – Who is responsible? Rebar Stability

We recently had a temporary works problem on site involving rebar stability for the columns (picture 2) below. The sub-contractor has argued that the principal designer (PD) has given no considerations to buildability of the structure and has negated its responsibility under the CDM regulations. The principal designer argues that the temporary works are not their responsibility. The question arises: where the line is drawn for responsibilities in considering the buildability and structures in the temporary state?

Picture 1 – Example of reinforcement failure (not my site thankfully!)

Picture 2 – Abutment columns with deflection (my site)

Picture 3 – Abutment Columns with temporary propping and kickers cast to support main bars

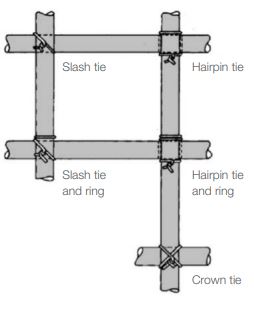

Picture 4 – different tying wire arrangements

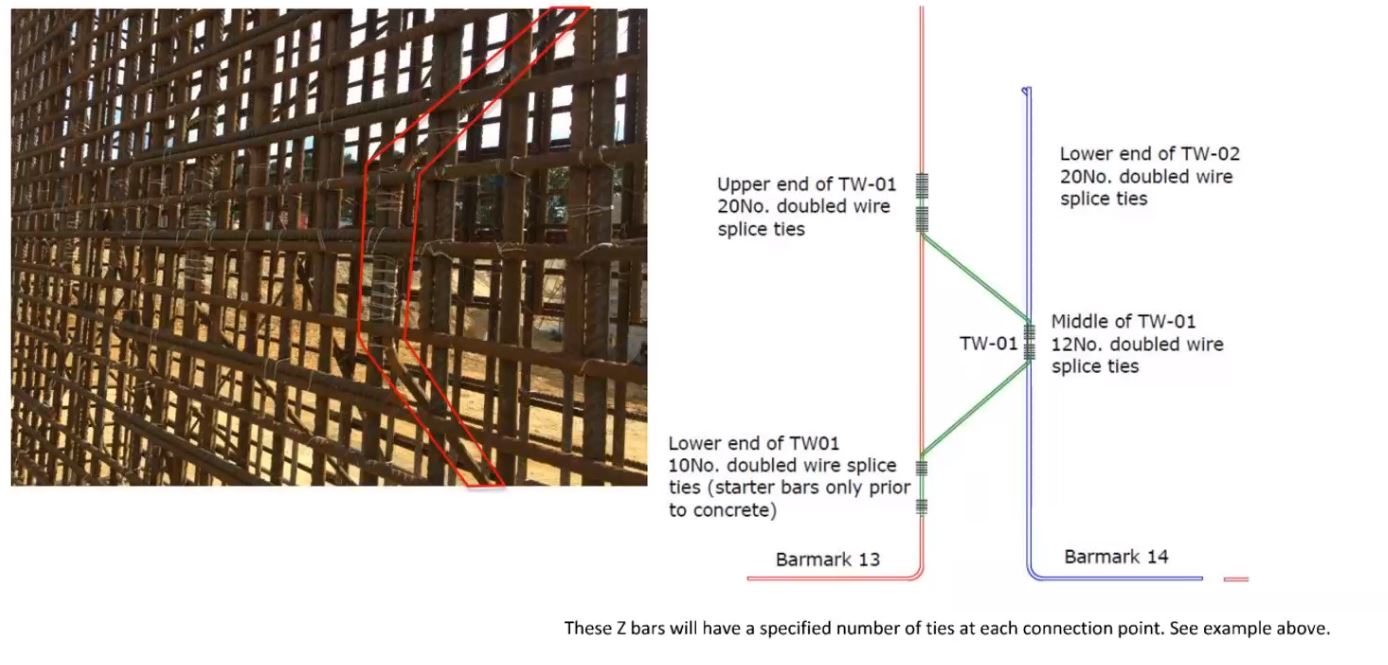

Picture 5 – Z bars and additional ties prescribed

Picture 6 – Racking failure with welded reinforcement

Picture 7 – Set up bars to aid fixing but can also be specified to support slabs

Personally, I think that any permanent works designer worth his salt should at least identify the specific risks in the temporary state. Merely, stating “temporary stability of the structure to be designed by others” is not acceptable in my opinion. As always time/money in the design office is always an issue as designers juggle several projects at any one time. Furthermore, I have experienced that some permanent works designers imply aren’t aware of the risks. How can the risks be eliminated if the risk is not known. Nevertheless, permanent works designers should always be receptive to design amendments proposed by sub-contractors an other designers to ensure schemes remain buildable.

The following website/blog produced by an independent consultant offers some interesting thoughts on the PD role.

The Temporary Works Forum (TWf) is an excellent starting place for any engineer. https://www.twforum.org.uk/home

For rebar stability, some (not all) of the failure modes and potential solutions are:

- Racking/Sway – diagonal z bars (square columns), propping the cage.

- Bending – erecting a one/two faces of a shutter before fixing steel or an access scaffold designed to support forces imparted by the reinforcement.

- Discontinuity Failure (ties fail/sliding of bars) – additional tying wire*, different tie patterns, welding of cages, casting a column kicker to allow main bars to rest on when connected to starter bars.

*1.6mm black – 280-320N/mm2 , 1.2mm stainless 600-800N/mm2 (TWf, 2020)

We’re all advocates for positive mental health, but are we REALLY doing enough?

(10 min read)

Please forgive me for straying momentarily from the core engineering discussions on this forum. I recently had a very positive experience at BP which gave me cause for introspection about my own and indeed the army’s approach to promoting positive mental health in the workplace.

Every Thursday afternoon, my department (Projects and Modifications) has an informal, no agenda “virtual coffee” meeting. The conversation usually meanders from COVID, to the dreadful Scottish weather, to Netflix, to weekend plans etc. Perhaps mindful of the fact that some personalities are naturally more dominant in driving the conversation, the P&M manager took the time to ask every single person on the call – “how are you doing XXX? How are things at work? How are things at home? etc”

The frankness of the responses were very surprising to me. Rather than just giving stock “yes all good here boss” responses, people were very open, with some sharing that they were feeling anxious and stressed right now, and explaining the contributing factors to their feelings. These statements were met with warmth and heartfelt support from the rest of the team, with several people going out of their way to offer help in any way that they could.

It’s immediately apparent to me that BP has developed a very inclusive, supportive culture, to the extent that staff feel empowered to be fully open and honest, displaying vulnerability without fear of judgment. Mental health struggles are wholly destigmatised, with an acceptance that periodic struggles are a natural part of modern living, and are no less common than physical ailments. Great emphasis is placed on personal well-being as a significant contributing factor to business success.

After this experience, I took some time to reflect on where we are in the army, and whether we could learn anything culturally from our civilian counterparts. In the broadest sense- I feel that the following comparison sums up the difference between BP and the Army.

At BP, your personal struggles, once shared, become the team’s struggle. The success of the team depends on the collective finding a solution. In the Army, it is generally expected that you deal with your own problems, in order to be able to contribute to the success of the team.

This comparison is, of course, tinged with personal experience and as such is likely to be subject to all associated biases. I’ve expanded on some of my reflections below; I’m very keen to generate some discussion about this and by all means feel free to flat-out disagree with me if you think I’m way off the mark.

- The army, culturally, has arguably not yet made the leap of de-coupling an individual’s periodic/episodic mental struggles from their general strength of character. This is a contentious point, but I would argue that there exists a heightened reluctance to speak up if you’re struggling, for fear of being adjudged to be a weak person/leader compared to your peers, in the eyes of the chain of command. I think this is also exacerbated by the disproportionate emphasis (particularly in the officer corps) placed on promotion, meaning individuals may sacrifice their own mental health for fear of losing a competitive edge.

- The army can sometimes overstate the “warfighting organisation” mentality, to the detriment of team cohesion. What I mean by this is that we ought not to list mental fortitude as an expectation of a soldier on operations, without first creating a culture in barracks that promotes and develops it as a key soldiering skill. I’m not for a second suggesting that we shy away from the harsh realities of what the army exists for, and what it can ultimately be expected to do on operations, but creating circumstances whereby a soldier’s mental health is nutured and developed to the same extent that physical health currently is would arguably contribute to greater operational effectiveness. That starts with enabling an environment where everybody feels empowered to be their raw, honest selves. The hierarchical system that we adhere to doesn’t necessarily marry neatly with this, but it shouldn’t be an insurmountable obstacle.

This blog wasn’t intended to be a slanderous indictment of the army as an employer that doesn’t care about the mental well-being of its people. Of course we all care. Indeed, mental health awareness (most notably with PTSD diagnosis and treatment) has made great strides forwards even in my short time in service. But we can do more. Having seen at BP how effective teams can be in such an inclusive, accepting environment, I feel obligated to personally improve my approach once I get back in my green pyjamas. As shown in the example of our virtual coffee meeting, the culture starts with strong leadership to set the tone. I would urge every one of us, as officers, to do more, listen more and help more, for the good of our people and the army.