CDM – Who is responsible? Rebar Stability

We recently had a temporary works problem on site involving rebar stability for the columns (picture 2) below. The sub-contractor has argued that the principal designer (PD) has given no considerations to buildability of the structure and has negated its responsibility under the CDM regulations. The principal designer argues that the temporary works are not their responsibility. The question arises: where the line is drawn for responsibilities in considering the buildability and structures in the temporary state?

Picture 1 – Example of reinforcement failure (not my site thankfully!)

Picture 2 – Abutment columns with deflection (my site)

Picture 3 – Abutment Columns with temporary propping and kickers cast to support main bars

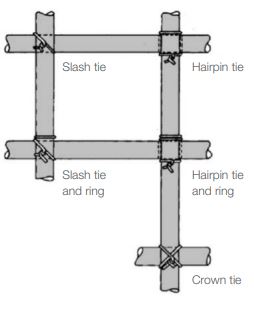

Picture 4 – different tying wire arrangements

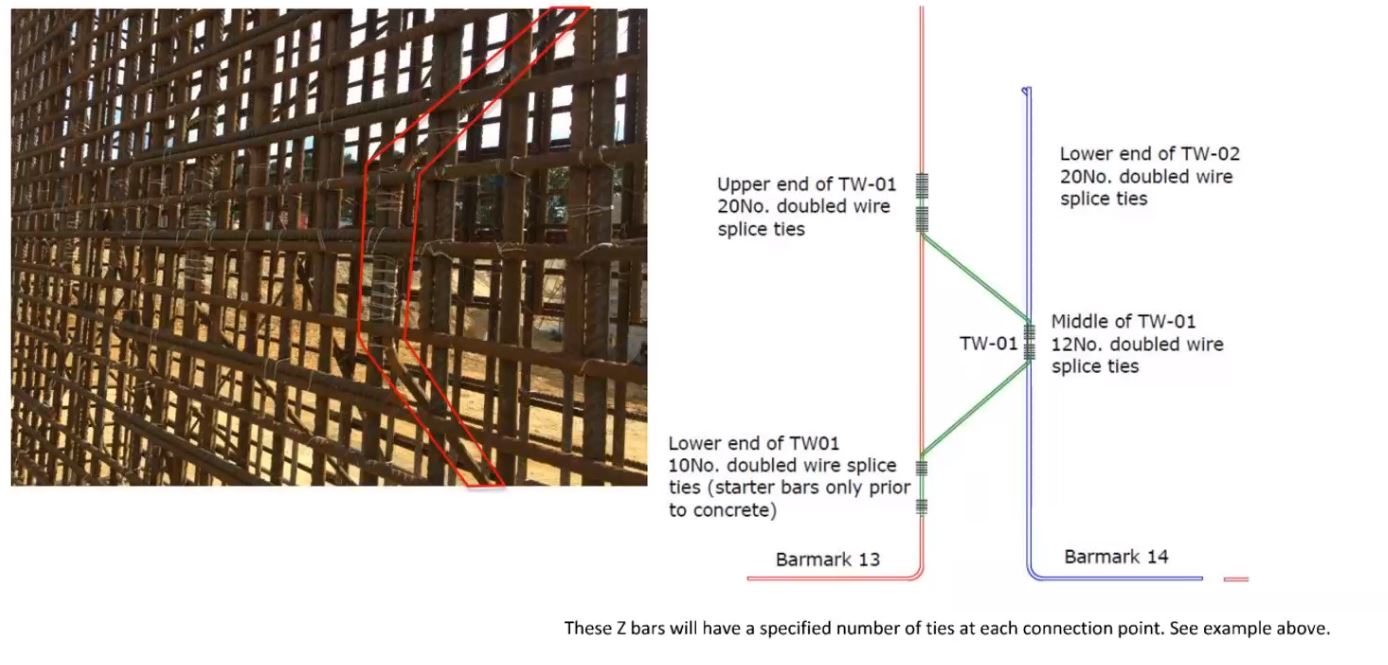

Picture 5 – Z bars and additional ties prescribed

Picture 6 – Racking failure with welded reinforcement

Picture 7 – Set up bars to aid fixing but can also be specified to support slabs

Personally, I think that any permanent works designer worth his salt should at least identify the specific risks in the temporary state. Merely, stating “temporary stability of the structure to be designed by others” is not acceptable in my opinion. As always time/money in the design office is always an issue as designers juggle several projects at any one time. Furthermore, I have experienced that some permanent works designers imply aren’t aware of the risks. How can the risks be eliminated if the risk is not known. Nevertheless, permanent works designers should always be receptive to design amendments proposed by sub-contractors an other designers to ensure schemes remain buildable.

The following website/blog produced by an independent consultant offers some interesting thoughts on the PD role.

The Temporary Works Forum (TWf) is an excellent starting place for any engineer. https://www.twforum.org.uk/home

For rebar stability, some (not all) of the failure modes and potential solutions are:

- Racking/Sway – diagonal z bars (square columns), propping the cage.

- Bending – erecting a one/two faces of a shutter before fixing steel or an access scaffold designed to support forces imparted by the reinforcement.

- Discontinuity Failure (ties fail/sliding of bars) – additional tying wire*, different tie patterns, welding of cages, casting a column kicker to allow main bars to rest on when connected to starter bars.

*1.6mm black – 280-320N/mm2 , 1.2mm stainless 600-800N/mm2 (TWf, 2020)

This is interesting and will no doubt continue to be a bone of contention between the PC and the SC. Notwithstanding it would have been helpful if the PD had considered the temporary state in design, I would have thought that it would have been more helpful to everyone if the buildability of the structure had been considered by the SC during the tender process and priced into their quote? This would be my expectation if I was a PC hiring a ‘competent SC’.

What was the solution after all? Who took responsibility for the delay/cost of temporary works solution? On my site we had a similar issue where our PD had designed a steel cage for the reinforcement of a concrete jacking collar. Once the SC had fixed the cage on site they tried to lift it (with a mobile crane) to find that the lifting method they had submitted and had approved (by us) led to too great a deflection in the cage and the lift being deemed unsafe (essentially the cage couldn’t support its own weight being lifted from each corner). In this instance the SC beared the cost of re-submission of the lift plan and standing time for the mobile crane and workforce at about £10k a day.

Good question

I think that underlying all of this is that:

a) Consultants spent so many years avoiding TW design- or not really considering it- that it is now the preserve of the strange TW designers

b) Only in fairly extreme cases will a cage lift be designed. The last similar issue I saw was at Hinkley point. Here the cage positioning had to be really precise ( in a nuclear encasement dome) yet the lift design had been left to the last minute and the issue was deformation of the cage in lift.

c) PC’s just farm out everything to ‘specialists’ The larger TW outfits ( Keltbray and Carey’s for example) have their own design teams and are capable and probably deal with this sort of thing.

I think the sad fact is that , what the PMs see is engineering that no one takes responsibility for because no one is clearly paid for the task and , in the end , it is dealt with through engineering BUT that that becomes to be seen as an ‘on cost’.

So consider:

The engineer considers and solves before execution – but no one will pay

The engineer solves at the last minute , when the thing has become critical and engineers are blames for the oversight and for costing more