Archive

My piles

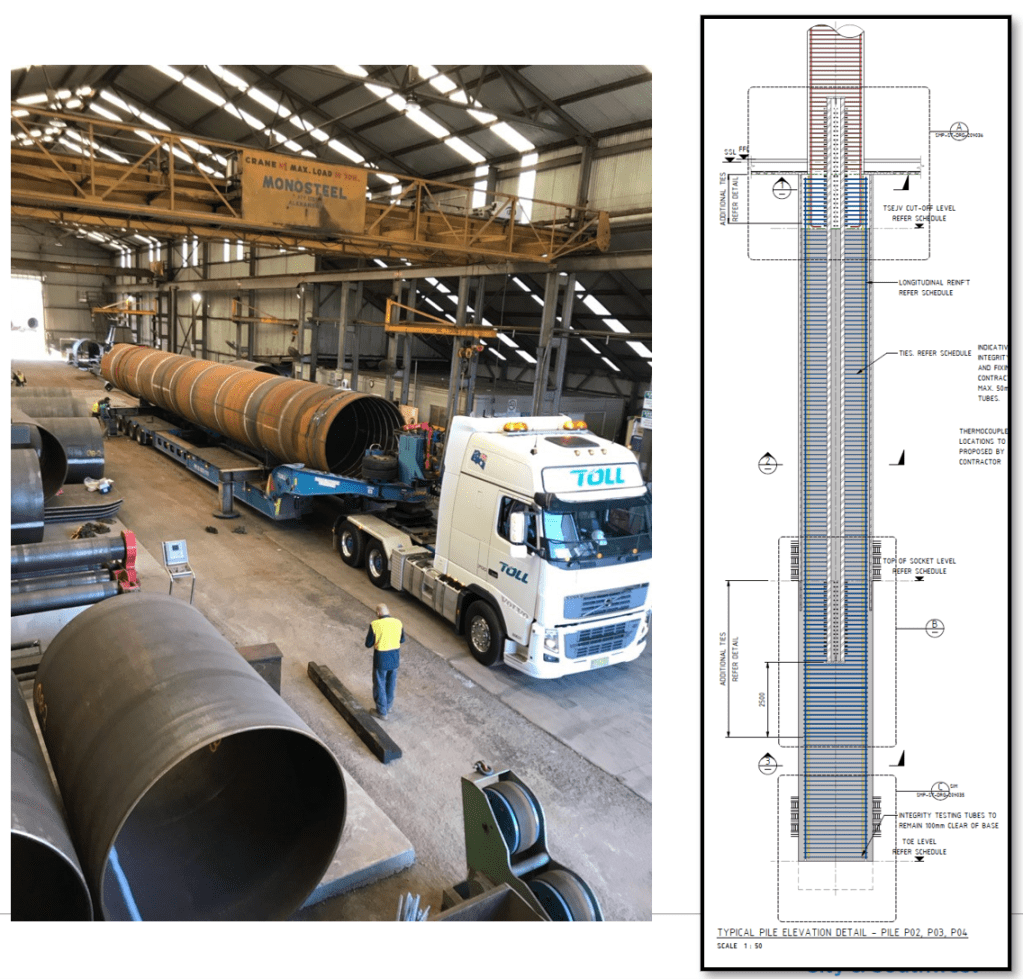

The Tunneling and Station Excavation contract at Martin Place includes the construction of 14 steel reinforced concrete piles. Each pile has a steel sleeve (max 24.1m – approx. 56t) and then a 50mm wide void to the surrounding rock for seismic loading. Three of the piles have a steel plunge column (max 29.6m long – approx. 40t) and the rest have a steel reinforcement cage installed in 3-4 spliced sections. 60MPa concrete was poured in each column using a tremie pipe.

The piles were cored using a BG40 Piling Rig and installed in 2019 prior to my arrival in Sydney however I have been in charge of trimming and ‘finishing’ the piles ready for handover to the follow on contractor this month. My scope of works and assessment of the drawings raised two terms I was unfamiliar with: CSL and TIP. 5 piles were tested for CSL and TIP and I now need to grout the CSL tubes…what are they?

Thermal Integrity Profiling (TIP)

What. A non-destructive testing method to evaluate the integrity of concrete foundations.

How.

- Place sacrificial thermal monitors along the full length of the pile, attached to the longitudinal steel reinforcement.

- Connect wire to data loggers at the top of the pile.

- Start logging prior to the concrete pour and measure the heat generated either throughout the cement hydration process or at a set time prior to the expected peak curing temperature.

- Compare the predicted and observed thermal profile.

Why. Quality assurance to prove the quality of both a piles cross-section and entire length. Deviations from the expected thermal profile indicate defects. Cool areas, shortage of concrete, i.e. necking or inclusions. Warmer areas, excess concrete, i.e. bulging and over pour. Analysis of the thermal profile can also assess if the reinforcing cage is properly aligned and centered. TIP testing is usually complete with 72 hours of a pile being cast and is the first test that can indicate in issue with a pile.

*Note, do not google TIP for piles, you end up on an NHS self-help page.

Cross Hole Sonic Logging (CSL)

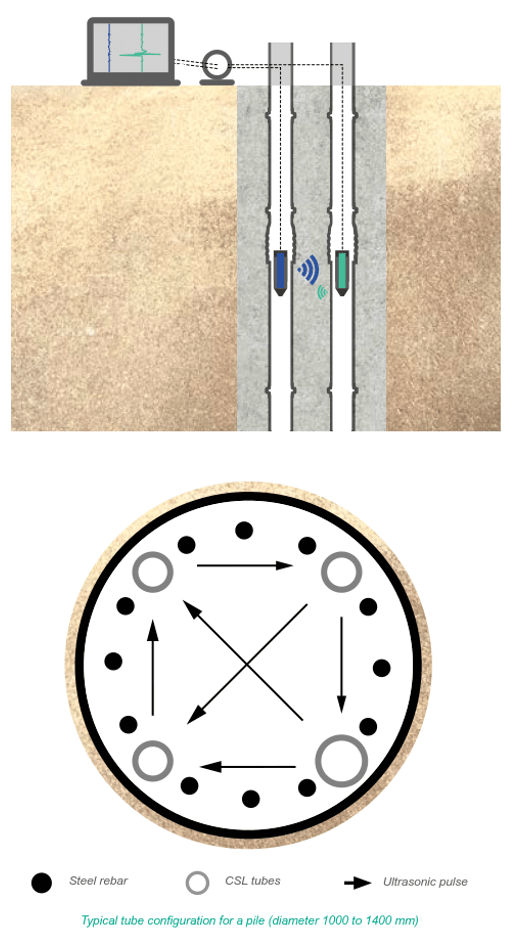

What. A non destructive test method to test for the structural integrity of a pile. Sound concrete is only checked inside of the steel reinforcement cage and not the concrete cover. Also known as cross hole acoustic testing.

How.

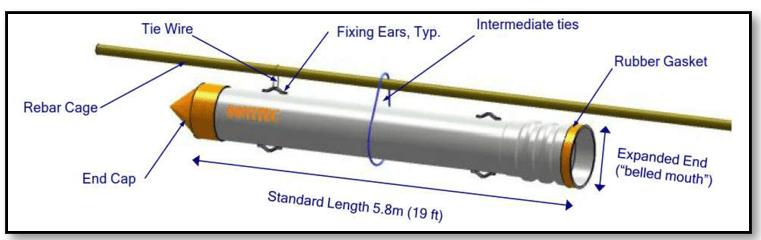

- Steel access tubes are installed inside the fabricated steel reo cage. In this instance every 300mm around the diameter. Check straightness, end caps installed, intermediate sections secured, bottom and top caps fitted. (Often CSL tubes are prefabricated by the cage supplier).

- Post installation, tubes will be filled with water.

- Post concreting, tubes will be checked for any blockage and this will be carried out by lowering weighted tape.

- Piles will be tested after 3 or 7 days post concreting and before 28days.

-Sound source lowered into a tube.

-Sensor lowered into the opposite tube to the same depth.

-Sonic pulse emitted. Relative energy, waveform and differential time are recorded, and logged.

-Procedure is repeated at regular intervals throughout the pile and then mapped. - Combination of graphs compared to identify flaws in the concrete.

- Once testing is complete and piles accepted by designers, the tubes will be grouted with 65MPa grout.

So there we go. Now I knew the purpose of the wires and tubes sticking out of the top of the pile I was looking at!

Due to access and programme a number of the piles had not been finished at the time of installation. Half had been covered up under steel plates across site for over 6 months and now needed to be dug out, 2m of sacrificial poor concrete hammered out and then have the remaining reo tied prior to inspection and sign off from the designer and IC. A few photos below of the fun that entailed and some points for discussion.

- Who conducts the TIP and CSL testing? Ours was done by the piling subcontractor, Bauer.

- Has anyone used the proper brush gaskets to maintain a clear void? For some reason despite being part of the initial planning we ended up using pool noodles!

- H&S for the subcontractor hammering inside the pile. We had to use a tripod and harness for emergency evacuation. Monitoring of live edges and enforced pairs working with a spotter at the top of the pile.

- The pile shall be trimmed to a specified cut off level leaving only sound, well compacted concrete on the surface of the pile head (as per the ITP). ‘Sound concrete’ at the pile trim level was determined by visual inspection of adequate aggregate and a few hits with a hammer to check none cracked away. This appears to me rather informal as opposed to a qualitative physical approach such as Schmidt Hammer?