Archive

My biggest fan – 15min read

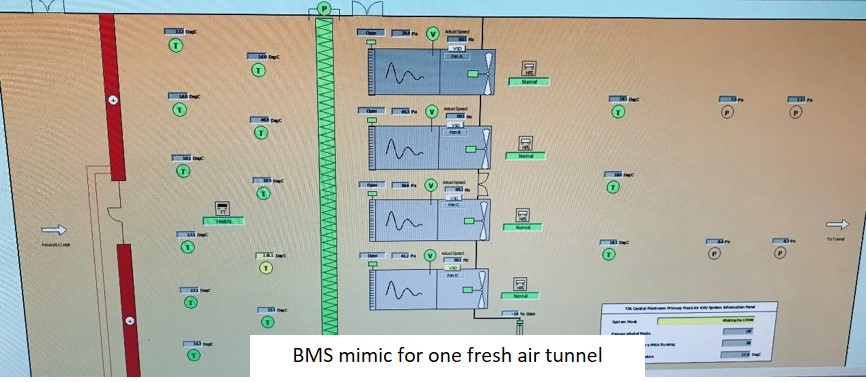

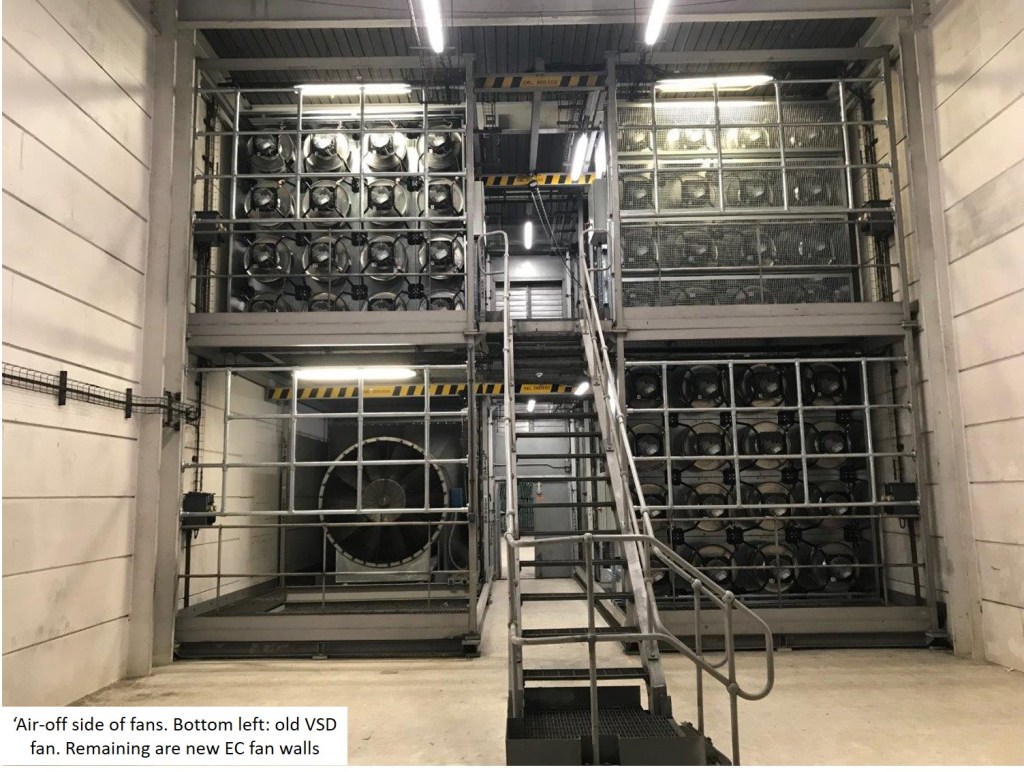

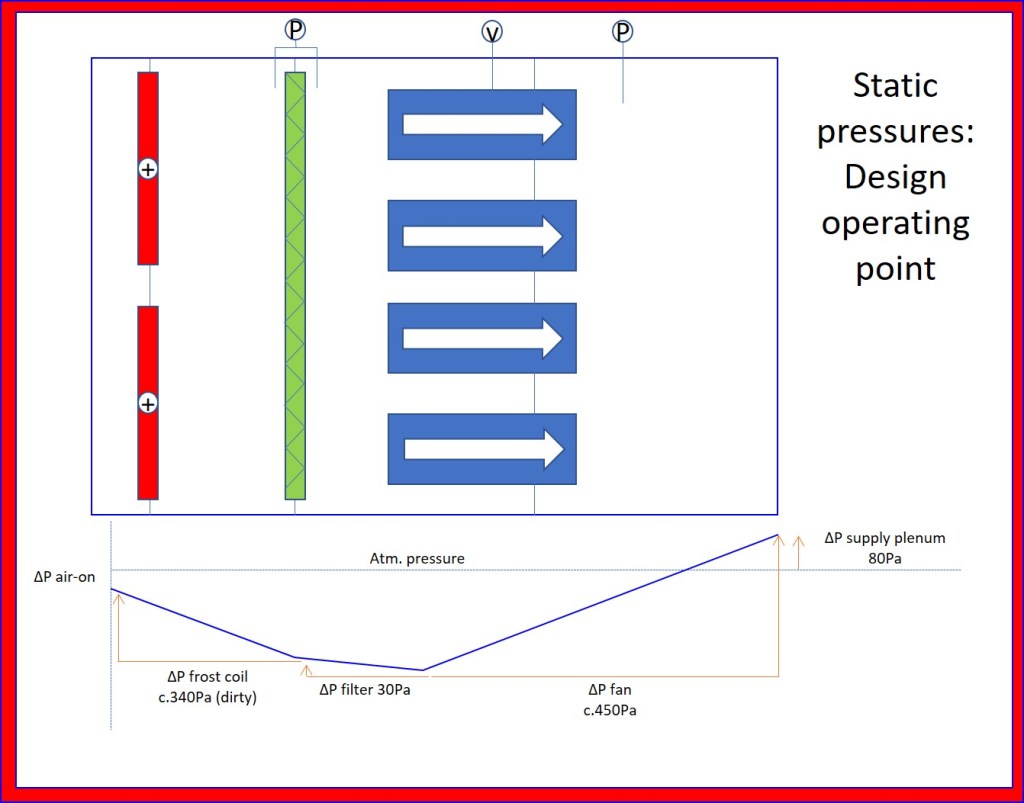

Part of the portfolio I have responsibility over as PM is the replacement of variable speed drive (VSD) motors with the retrofitting of electronically commutated (EC) fan-motor units (energy efficient motors, DC brushless motors by another name, sorry for the simplification John Marsh!). One of the sub projects is the removal of the original VSD fans from the three primary fresh air tunnels which provide fresh air to Terminal 5A. Essentially, there are three tunnels each with design flow rates of between 180 and 240 m3/s and a downstream plenum pressure set point of 80 Pa. These design conditions allow the AHUs within the terminal building to be able to ‘suck’ (I know pumps only ever push, Mark Hill!) fresh air into occupied spaces within the building. Each of the old VSD fans was replaced with a fan-wall composed of multiple EC fans.

The project was completed in late 2019 and the static pressure in the plenum has never consistently reached the 80 Pa set point. There has been multiple inspections and heated conversations over who is to blame.

On the client side, Heathrow are clearly disgruntled at the increased energy demand of the fans, currently running at 100% (with no redundancy) and not meeting operating conditions. The operational engineering team within the terminal believe it to be a lack of capacity from the newly installed EC fans.

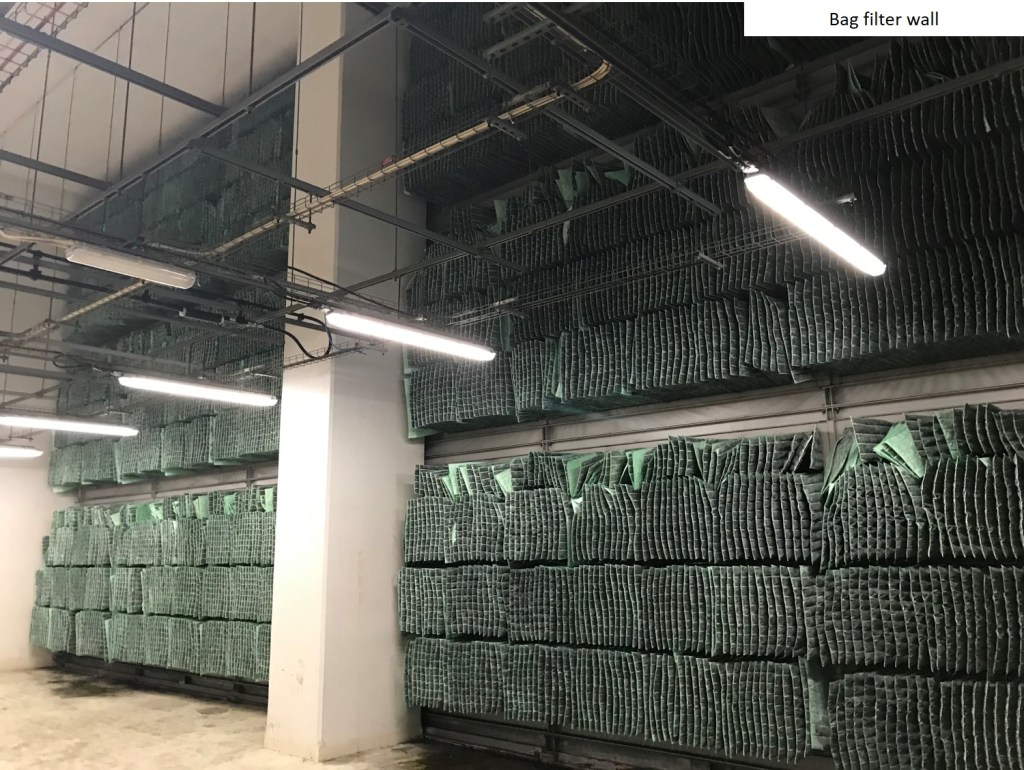

On the contractor side, they believe the fans are being ‘choked’ through poor cleaning and maintenance of the frost coil and bag filters that are the in the system and that the design is as specified by the original project scope.

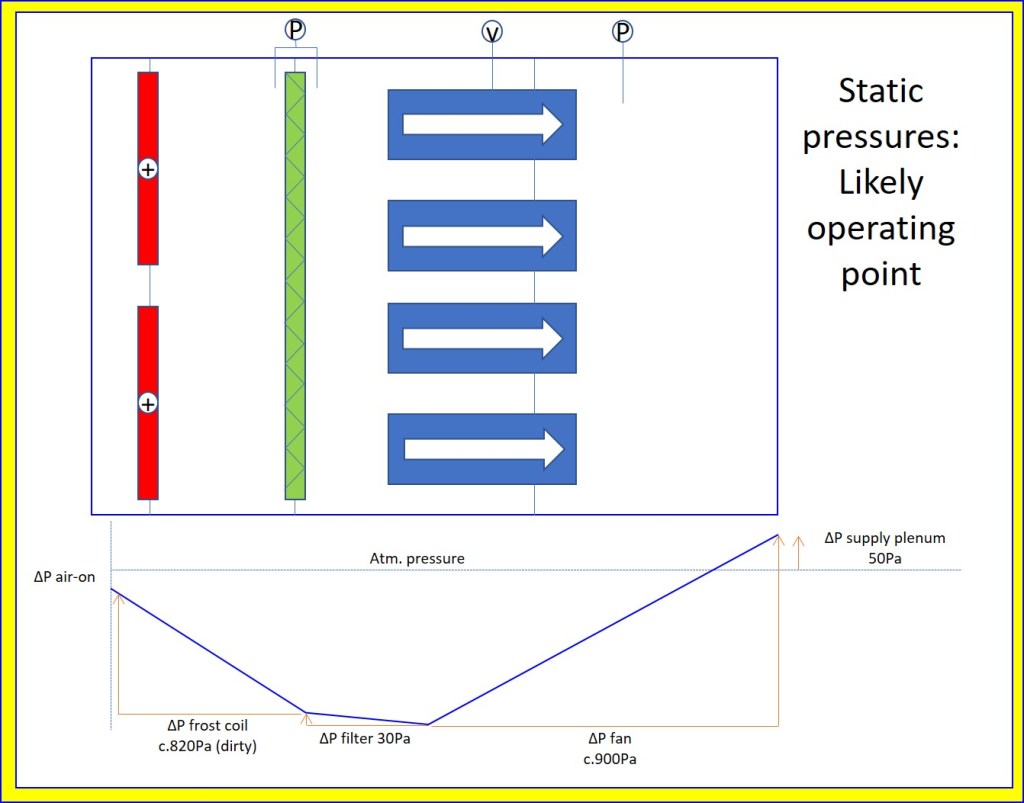

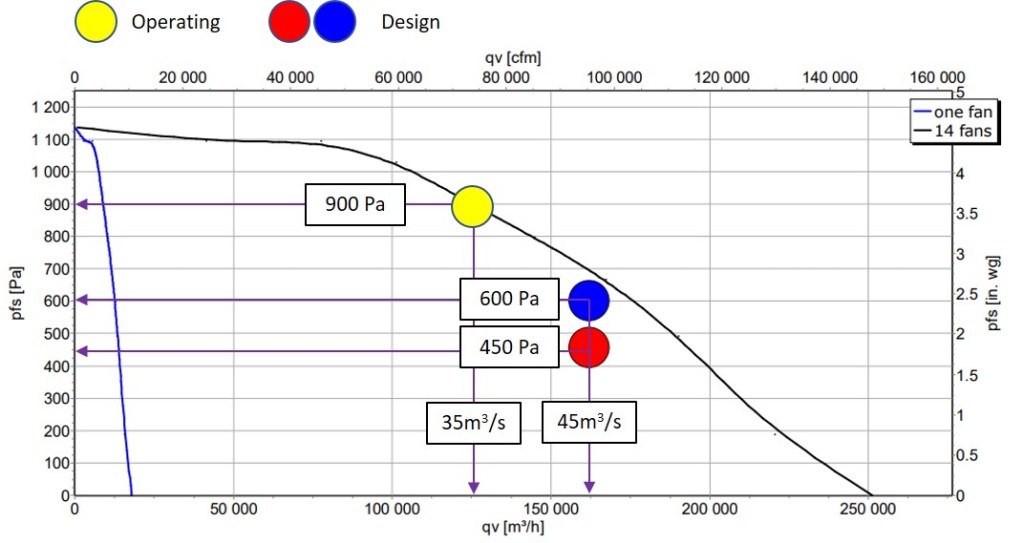

There had been a plan to install more pressure and temperature sensors within the tunnel but at this time there is no way to measure differential pressure across the frost coil or fans. The manufacturer of the EC fans published the fan-curve data as in the figure with the two operating points based on the original project scope that was handed to them in early 2019. Original commissioning information puts the maximum allowable differential pressure across the frost coil as 50 Pa and the bag filters at 225Pa. The frost coils are currently extremely dirty and gummed with incoming material entrained in fresh air. Although DP across the frost coils cannot be directly determined the bag filters are not running at anywhere near this upper limit.

The figures below show the likely operating conditions as is, along with the two cases published by the manufacturer, IF the EC fans are performing as per the published fan-curve.

Research into original commissioning information has revealed that there is a large difference between the maximum available duty of the VSD fans removed and the smaller EC fans retrofitted. Although this extra duty is not required in ‘normal’ operating conditions (ie. if the filters and coils remain clean and with low enough DP) in the past it could have easily allowed to overcome poor cleaning and maintenance of components by simply ‘turning it up to 11’.

Following some investigation I think there to be are a number of possible outcomes, in order of likelihood, following the correct cleaning of the frost coils an replacement of bag filters:

- The system will operate correctly and pressure set point is reached. Everybody goes home happy and electricity bills reduce.

- There still lacks the sufficient pressure in the fresh air plenum. This will then cast doubt upon the EC fan capacity and likely reveal that the original scope handed to the manufacturer did not allow for the total air flow capacity of the original VSD fans; no fault of the designer. Due to the size of the project this will likely be tolerated and downstream operation strategy of AHUs will have to change from working on pressure set points to perhaps CO2 levels.

- The EC fans are found to be lacking still and only through extra monitoring of running conditions of the fans (differential pressures and air volumes) the manufacturer is held to account.