Archive

Novel vehicle protection against IEDs

Well over half of the deaths of British troops in Iraq and Afghanistan over the past twenty years were due to improvised explosive devices (IEDs). As these operations progressed, military vehicle designs were adjusted to mitigate this threat, namely in the form of V-shaped hulls and extra armour to re-direct the blast wave and protect the occupants from shrapnel.

Advanced Blast And Ballistic Systems LTD has developed a new approach to IED defence which uses the same principle as that seen in the Explosive Reactive Armour (ERA) used by modern day main battle tanks; namely the use of an equal and opposite reaction (Newton, 1687). This novel system employs rockets to provide a counteractive force during an IED blast, keeping the vehicle stable and thereby reducing injury to those inside. A more thorough explanation can be found in the video below:

RMD Megashors: Failing by over 30%

Project: Fulham Riverside.

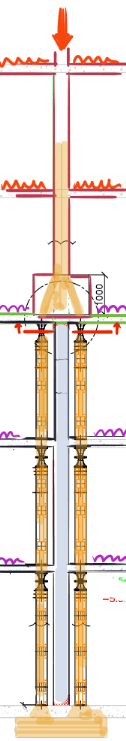

Context: RC framed multi storey building. Constructed. Columns needed to be replaced. This required temporary propping. Propping designed by external company consisting of RMD Megashors. The consultancy I’m working for were asked to check the scheme.

Event: We identified that the Megashors were inadequate for the loads. Failing by over 30%. The external temporary works designers had calculated the prop loading correctly, however they used an incorrect prop capacity. The capacities used were taken from an out of date datasheet.

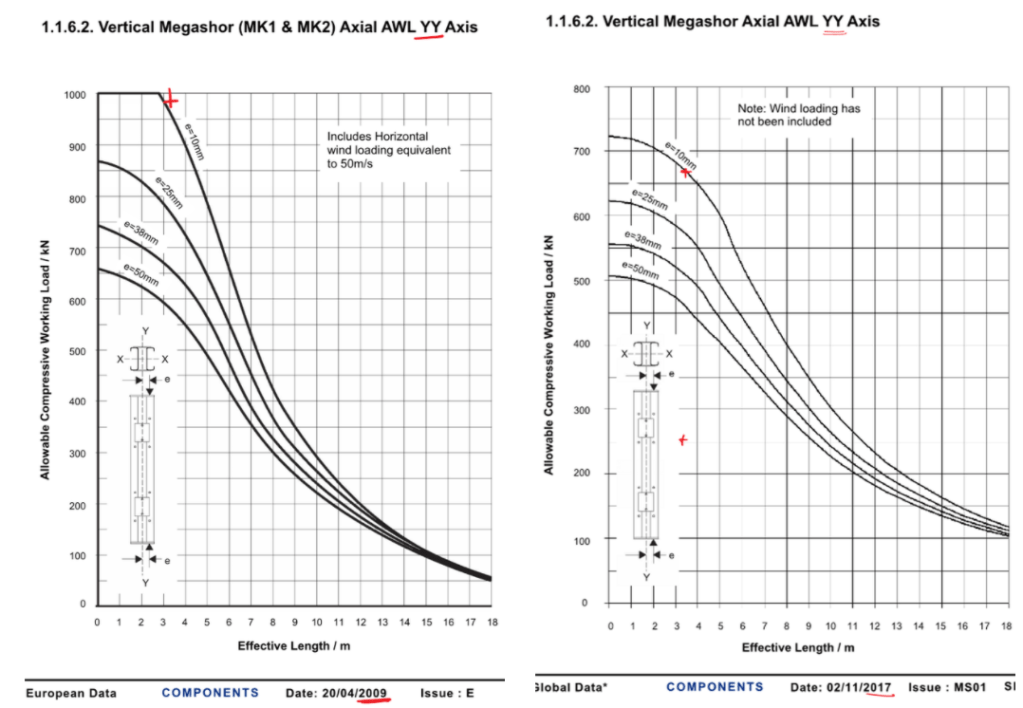

A few years ago, the published capacities of RMD Megashors were significantly reduced. This occurred because one of the manufacturers had used an inferior grade of steel for a period of time. You can see from the diagrams below, taken from the technical literature from 2009 and 2017, that for a 3.5m effective length, the capacity has been downgraded by nearly 250kN!

Interestingly, the external temporary works designer knew about this however he was led to believe by his supplier that the RMD props that were being provided to him were of the higher grade. However, when asked, the supplier was not able to confirm this with documentation.

To compound the issue, when RMD originally published this, they announced that they had no method of identification (e.g. batch number or serial number) on the props, so determining the age of a prop and therefore which grade of steel is near impossible. This is why they took the huge commercial decision to downrate all of their Megashors. I guess it could be easier for a supplier as they would know when they bought their props, rather than RMD who I’d assume have a floating stock that is regularly replenished.

It is also interesting to note that the old spec allows for 50m/s wind as a horizontal load, but the new one doesn’t allow for any.

Lessons Learnt: When using RMD megashors, ensure that you are using the latest technical datasheet. If a supplier says that their grade is of superior grade, then the onus is on them to prove this.

The 2017 Megashore datasheet can be found here so you don’t get caught out although this demonstrates that it’s always worth checking to see if there’s a newer version!