Archive

Flexible Working

Just wanted to start a discussion on how the construction industry will change as a result of Covid-19. Arup have just made a big announcement about global flexible working, 3 days in the office a week and flexible hours. Allowing employees to work their 7.5 hours a day when it suits them but facilitating crucial collaborative work with teams coming into the office. There are many pros and cons to flexi working but I quite like the idea of this mix and it will be interesting to see how it plays out. Some other thoughts on flexi working:

- Time in the office is really important for developing junior engineers.

- Companies that do not offer flexi working may loose out as people seek roles in companies with a flexi policy.

- Line management of individuals is key to ensure that work patterns meet team and project outcomes.

Another area of interest is how construction firms can adapt to offer roles to people with disabilities. I have conducted a site visit from the design office with a person who uses a walking cane. He drove to the visit and the whole site was accessible due to AliMak lifts between levels (it was a tunnel site) and a few stairs he could manage here and there, see image below. This is particularly pertinent for design offices where people are employed for their brains! He is an Associate Principal with 20 years experience and a technical leader in retaining structures. Arup have been named in the Valuable 500 a global movement putting disability on the business leadership agenda. A campaign to get 500 national and multinational, private sector corporations to be the tipping-point for change and help unlock the social and economic value of people living with disabilities across the world. Because the potential of 1.3 billion should not be ignored.

Arup makes flexible working permanent for UK staff | Construction Enquirer News

Drafting complex 3D structures – 2 min read

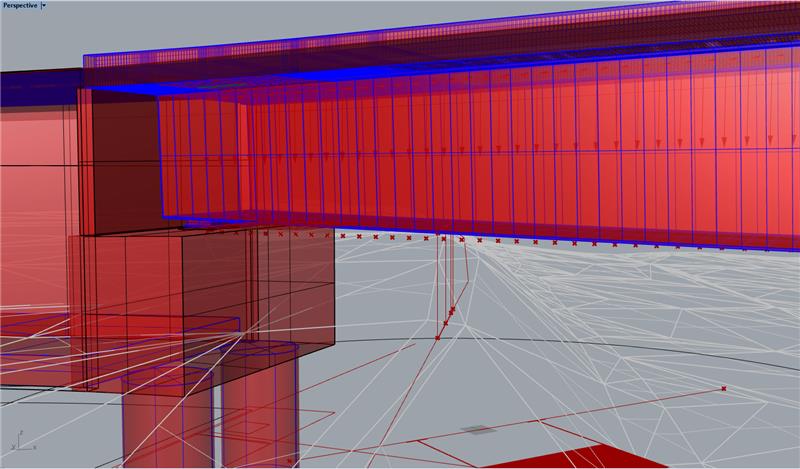

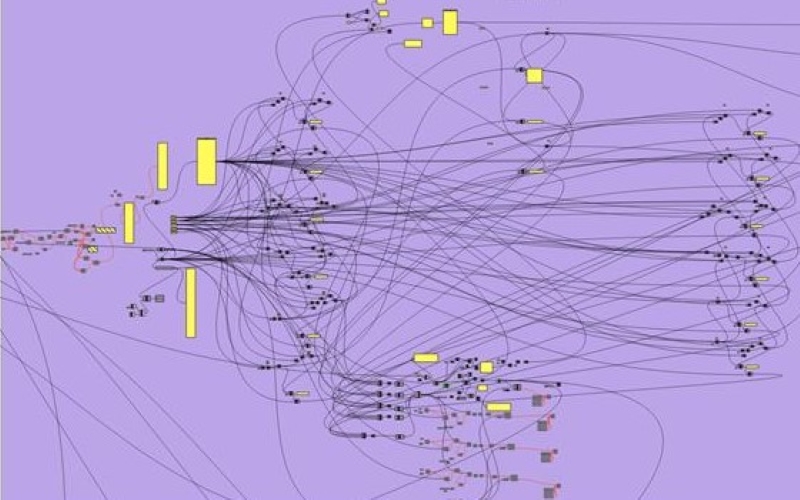

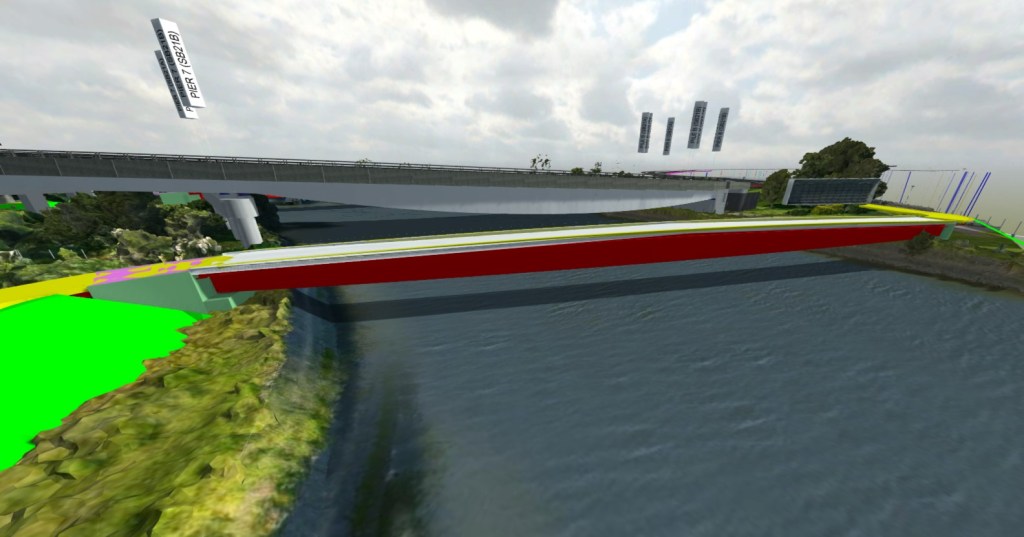

Building 3D models of bridges with complex geometries is beyond anything I can do in Revit. With varying curvatures in up to three dimensions it can take the bridge drafters a while to build the 3D models.

To do this the drafting team use a visual programming language which plugs in to 3D modelling software. To me the programming looks extremely complex but on a basic level appears pretty intuitive. Using this they are able to model the bridges. Importantly it allows different drafters (in separate countries) to quickly understand and update the models.

The design consultant I have been attached to now exclusively use Revit on all building projects. However, the bridge team only use it on about half of the bridges with the other half being drafted in AutoCAD. Fundamentally though there isn’t much of a difference between the two. The Revit drafters use a DYNAMO visual programming language plugin while the AutoCAD drafters use Grasshopper 3D (visual programming language) and Rhino 3D (3D modelling software). With a lot of bridge drafting still done in 2D (cross bracing would take a long time to model in 3D) I can see why Revit has not been fully adopted. However, the bridge drafters believe that in 5-10 years they will be exclusively using Revit.

Train Spotting

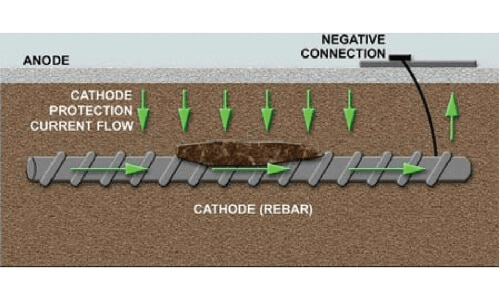

Now that I am officially into trains, or at least have been involved in metro, heavy rail and light rail projects, I wanted to write a quick blog about stray currents. Any current that leaks from the rails and conducts through any path, other than the dedicated return path, is known as stray traction current. As can be seen below stray current moves through the ground, ground water and potentially through surrounding structures.

Why this is important for civils, mech and elec? Corrosion. Whether you are designing and constructing the tunnels for the track to run through, station services and signalling, substations which power the rail and surrounding utilities protection against stray current will need to be factored into your design. Remember the school science experiment with a battery and beaker of electrolyte? Build a rail system and you have one big experiment, only now the corrosion will disintegrate your utilities pipe or the steel reinforcement in your concrete rather than the little piece of metal in the lab.

An electrolysis desktop study is used to identify the measures that should be taken to ensure stray traction current does not present a corrosion hazard to a proposed development. There are 4 key protection measures;

- The installation of heavy plastic membrane under (or behind) all reinforced concrete slabs, metallic platforms/gratings, piers/piles and metallic posts/bollards to electrically isolate from soil and the stray currents.

- Any steel reinforced piers/piles and metallic posts/bollards to be concrete grout encased.

- The use of plastic, rather than metallic, in-ground pipework where possible. In the event buried metallic pipework and/or cables are installed within the site, installation within sealed non-metallic conduit is recommended.

- The use of minimum 32MPa, high cover (min 50mm) concrete to limit moisture penetration to the embedded steel.

Infrastructure has a 100 year design life, beyond that of the measures listed above therefore cathodic protection is installed. Reinforcement bars are welded together to generate a loop through the structure. Generally two loops are created (redundancy) and tested for continuity prior to concrete being poured (site engineers ITP quality checks). An electrolysis point is installed at the surface of the concrete and a sacrificial anode can be attached.

Anyhow a little insight into stray currents and corrosion protection. I had never heard of this prior to arriving on site. Has anyone else had any experience?

Living a double life: Lessons from parallel careers in civil and military engineering

Upcoming ICE Webinar: Wed 19 May 2021 (1730-1900BST)

Link to book: Living a double life

If available please support a friend of mine, Captain James Glass, in his upcoming ICE Webinar where he will be discussing his experiences working as a Civil Engineer in the Oil & Gas industry and as a reserve in the Royal Engineers. Amongst other things, James was deployed on TRENTON 7 (South Sudan) as the Garrison Engineer and will be discussing the Bentiu quarry which he recommended the UN close due to significant risk to life. This segment of the webinar will include an overview of his quarry assessment and the remedial works completed to date.

ICE Event Summary:

Join ICE East Midlands Nottingham, Leicester, and Derby (NLD) Branch for a presentation from Captain James Glass of the Corps of Royal Engineers as he identifies from his own experience how the disciplines in civilian and military engineering differ in the 21st Century.

From a Civil Engineer in the Oil & Gas industry to an Army Reserve Officer within the 65 Works Group Royal Engineers, Captain James Glass has led engineering design and delivery teams on operations in Afghanistan, Iraq and South Sudan providing critical engineering support to Defence in the UK and overseas operations.

Captain Glass will draw on case studies from these projects, the challenges faced and the lessons that can be shared between engineering fields as he reflects on six years of his civilian and military engineering career and experience.

The Construction Playbook

Further to Jordan’s post. Another piece of signposting for essential industry reading. In December the UK Govt launched the Construction Playbook in order to help make sure Govt civil engineering projects, particularly infrastructure, are delivered in a more sustainable way and on time.

Government Guidance on sourcing and contracting public works projects and programmes.

Ten min intro video here: The Plan To Change Construction – YouTube