Train Spotting

Now that I am officially into trains, or at least have been involved in metro, heavy rail and light rail projects, I wanted to write a quick blog about stray currents. Any current that leaks from the rails and conducts through any path, other than the dedicated return path, is known as stray traction current. As can be seen below stray current moves through the ground, ground water and potentially through surrounding structures.

Why this is important for civils, mech and elec? Corrosion. Whether you are designing and constructing the tunnels for the track to run through, station services and signalling, substations which power the rail and surrounding utilities protection against stray current will need to be factored into your design. Remember the school science experiment with a battery and beaker of electrolyte? Build a rail system and you have one big experiment, only now the corrosion will disintegrate your utilities pipe or the steel reinforcement in your concrete rather than the little piece of metal in the lab.

An electrolysis desktop study is used to identify the measures that should be taken to ensure stray traction current does not present a corrosion hazard to a proposed development. There are 4 key protection measures;

- The installation of heavy plastic membrane under (or behind) all reinforced concrete slabs, metallic platforms/gratings, piers/piles and metallic posts/bollards to electrically isolate from soil and the stray currents.

- Any steel reinforced piers/piles and metallic posts/bollards to be concrete grout encased.

- The use of plastic, rather than metallic, in-ground pipework where possible. In the event buried metallic pipework and/or cables are installed within the site, installation within sealed non-metallic conduit is recommended.

- The use of minimum 32MPa, high cover (min 50mm) concrete to limit moisture penetration to the embedded steel.

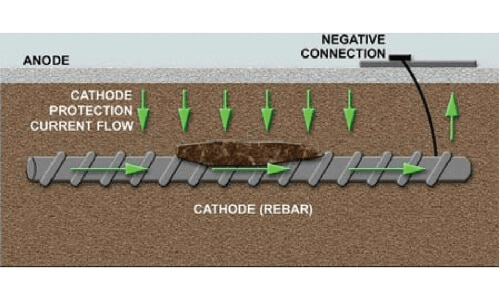

Infrastructure has a 100 year design life, beyond that of the measures listed above therefore cathodic protection is installed. Reinforcement bars are welded together to generate a loop through the structure. Generally two loops are created (redundancy) and tested for continuity prior to concrete being poured (site engineers ITP quality checks). An electrolysis point is installed at the surface of the concrete and a sacrificial anode can be attached.

Anyhow a little insight into stray currents and corrosion protection. I had never heard of this prior to arriving on site. Has anyone else had any experience?

Hi Claire, the thing that interests me is the idea of liability.

You’ve explained some of the measures one can take to protect their own new infrastructure from stray currents but how does the rail industry take precautions to protect insitu/third-party infrastructure. It’s too late to increase rebar cover or install plastic beneath concrete foundations so surely it’s the contractor’s responsibility to ensure third party assets aren’t affected, or else there may be a liability issue?