Archive

Design & Build – or Build, Design & Re-build?

The project I’m working on is using a ‘Mutual-Investment-Model’ (MIM) form of contract, which is a Welsh Government type of Private-Public-Partnership (PPP). As such a special purpose vehicle (SPV) (Known as Future Valleys Construction – FVC) has been formed with the main contractor (FCC) and designer (Atkins) both being part of Future Valleys Construction and operating a ‘design & build’ system to deliver the project. The Welsh Government has a minor equity stake in FVC and so any profits are in part shared between the Private and Public participants in the contract.

A key benefit of Design & Build contracts is that they allow for works to begin rapidly – in theory this should reduce the overall project duration, reducing cost, as design can keep pace with construction and issues be resolved as they materialise or are realised on site. In addition, from a client point of view the risk lies with the main contractor as a price is usually agreed up front for the delivery of the project – in the case of the A465 widening this is set at £590m.

Across the A465 widening scheme, and in particular on my site works are beginning before ‘for construction’ drawings have been issued and designs finalised. Work is being done using ‘for information drawings’. I have been told that this is to save time and allow the overall programme to be accelerated. However, I have come to question this logic.

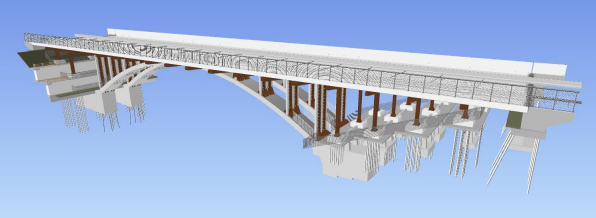

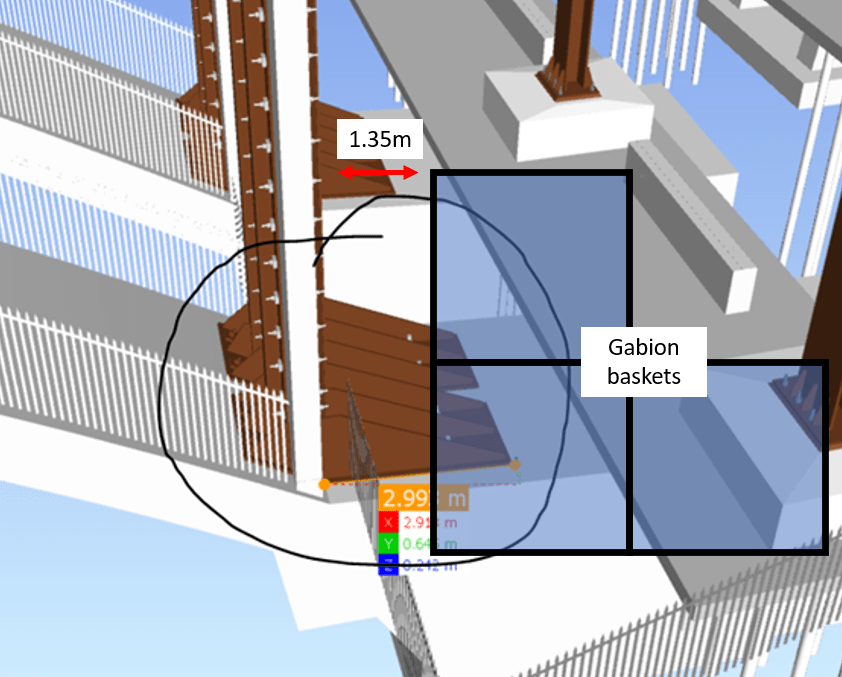

My project is a bridge strengthening and widening. In order to keep pace with the programme for the overall scheme, piling works must commence on my site on the 1 Jun 22. Pressure has been applied to start earlier. Currently on the East bank Gabion retaining walls for piling platforms (temp works) are being constructed and on the West Bank an access track cut so that retaining structures can be built there also. Both of these packages of work are forecast to be complete by late April (over a month in advance).

What has come to light since is several clashes with the permanent works which has forced a redesign of the temporary works. I have conducted my own initial review of the designers proposed solutions and believe that if they are accepted its likely that everything that has been built since my arrival on site may now be stripped out and rebuilt (which is equally soul destroying and comical). Not all of the materials used will be recoverable, meaning waste, environmental impact and cost. Plus the subcontractor executing the works has been charging day rates – further wasted cost. This is not only a significant financial expense, but also cuts into any profit share for both the public and private sector partners. In summary we have added significant cost and saved zero time – yet are still on track to be ready for piling on 1 June 22 so will not affect the overall programme.

To make matters worse, a 3D model exists of all the permanent structures on this scheme – by modelling the temporary works in the 3D models these clashes and issues would have been painfully obvious. Having asked why this isn’t happening I’ve been told ‘because the temp works change all the time its hard to model, we would have to keep re-modelling them’ – I was left pretty amazed by the reply, this is exactly why they need to be modelled! I am a complete convert to BIM for design and see just how beneficial it is to the industry. Having discussed this further with colleagues here I have realised just how unfamiliar any of the engineers are with REVIT or any other form of BIM.

I think for Design and Build to truly be beneficial and the benefits of BIM to be realised the process should be:

Partial Design (initial design) -> build virtually -> resolve issues -> build on site

What I am witnessing is this:

Partial design -> build on site -> identify issues -> re-design -> strip out and rebuild

Has anyone else had a similar experience? Has anyone actually saved time or cost in construction this way? What’s peoples experience on site been of BIM and modelling ahead of live construction?

What ARE we going to do with partial factors?

Firstly sorry about the Greek – difficult to do in this blog format

This si a live conservation regarding the current re-wrote of PAM 10 Structures for Operations.

The use of PAM 10 must be simple. It must be compliant with current structural design codes .

The current codes combine partial factor and limit state design.

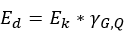

The fundamental equation for ultimate ( failure ) limits states requires that:

the design effect is less that the design resistance.

Crudely we can determine

to get to the design resistance we reduce the characteristic ( usually mean vale to resistance, say , material strength) to ensure that it is statistically unlikely to be lower than the value used in design.

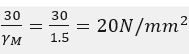

Although not straight-forward it could be envisaged that PAM 10 strength could be expressed as pre-factored so the resistance is determined directly using strength divided by a global gamma M ( for example C30 concrete has a strength of

The partial material factors used would be expressed in the refence documentation together with measures that PQE’s might take to vary risk.

The effects side of the equation is nominally

This implies we enhance actions to ensure that the design values are seldom less than actually applied . This is complicated by three issues:

| Issue | Description | Comment |

| Permanent .v. variable | Different actions are more variable than others. So permanent actions are increased by less than variable ones | Permanent actions are less variable than variable actions |

| Ultimate states .v. service states | Checks for failure Use the limit state in which the actions are factored up and resistance factored down Service checks do not factor actions( generally and use material properties that may or may not be factored | Generally stiffness is factored down for single elements but left at mean for systems ( like floor joists) |

| Multiple variable actions | When a design is checked with, say gravity and wind variable actions the dominant action is enhanced more than the secondary action | It is statistically unlikely that they are simultaneously at the extreme |

Since the narrative for PAM 10 is the management of risk – it seems sensible that some of the partial factor method is represented without having the full complication of full BS EN application.

We therefore would like the consideration of four possible options:

| Option | Resistance | Effect | Comment |

| 1 | Pre factored using recommended | Actions are pre-factored using appropriate gamma G and Q factors (ignoring further partial (psi) factoring of secondary variable actions ) | Resistance would be fairly faithful for design values Pre- factored actions would be difficult when either variable or permanent action dominated in a design . Would generally have to be taken on the high side |

| 2 | Pre factored using recommended | Actions are quoted as in various codes and are to be simply factored using fixed gamma G and Q partial factors ie ignoring further partial factoring ( psi for secondary variable actions ) | Resistance still recognizable Elements of the partial factor risk management seen in simplified action factoring |

| 3 | Resistance is to pre factored down using quoted gamma M and then further factored down using simplified gamma G,Q ( ie all the factoring on the material resistance side) | Actions are used, quoted as in various codes, without any factoring | Resistances would be about a third of the mean value Some conservatism would be embedded to allow for cases of high variable action component Actions used as is So ULS and SLS checks look similar in use |

| 4 | Resistance as quoted in BE EN with recommended partial factors quoted for use to be applied | Actions are quoted as in various codes and are to be simply factored using fixed gamma G and Q partial factors ie ignoring further partial factoring ( psi for secondary variable actions ) | Nearest to BS EN application |

DISCUSS