Design & Build – or Build, Design & Re-build?

The project I’m working on is using a ‘Mutual-Investment-Model’ (MIM) form of contract, which is a Welsh Government type of Private-Public-Partnership (PPP). As such a special purpose vehicle (SPV) (Known as Future Valleys Construction – FVC) has been formed with the main contractor (FCC) and designer (Atkins) both being part of Future Valleys Construction and operating a ‘design & build’ system to deliver the project. The Welsh Government has a minor equity stake in FVC and so any profits are in part shared between the Private and Public participants in the contract.

A key benefit of Design & Build contracts is that they allow for works to begin rapidly – in theory this should reduce the overall project duration, reducing cost, as design can keep pace with construction and issues be resolved as they materialise or are realised on site. In addition, from a client point of view the risk lies with the main contractor as a price is usually agreed up front for the delivery of the project – in the case of the A465 widening this is set at £590m.

Across the A465 widening scheme, and in particular on my site works are beginning before ‘for construction’ drawings have been issued and designs finalised. Work is being done using ‘for information drawings’. I have been told that this is to save time and allow the overall programme to be accelerated. However, I have come to question this logic.

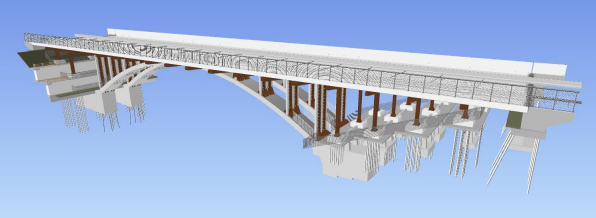

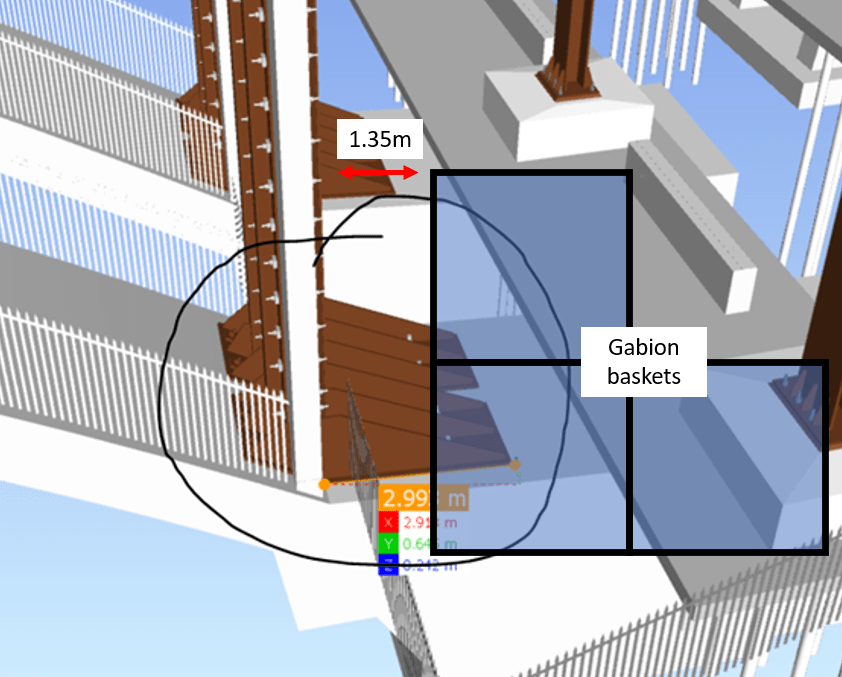

My project is a bridge strengthening and widening. In order to keep pace with the programme for the overall scheme, piling works must commence on my site on the 1 Jun 22. Pressure has been applied to start earlier. Currently on the East bank Gabion retaining walls for piling platforms (temp works) are being constructed and on the West Bank an access track cut so that retaining structures can be built there also. Both of these packages of work are forecast to be complete by late April (over a month in advance).

What has come to light since is several clashes with the permanent works which has forced a redesign of the temporary works. I have conducted my own initial review of the designers proposed solutions and believe that if they are accepted its likely that everything that has been built since my arrival on site may now be stripped out and rebuilt (which is equally soul destroying and comical). Not all of the materials used will be recoverable, meaning waste, environmental impact and cost. Plus the subcontractor executing the works has been charging day rates – further wasted cost. This is not only a significant financial expense, but also cuts into any profit share for both the public and private sector partners. In summary we have added significant cost and saved zero time – yet are still on track to be ready for piling on 1 June 22 so will not affect the overall programme.

To make matters worse, a 3D model exists of all the permanent structures on this scheme – by modelling the temporary works in the 3D models these clashes and issues would have been painfully obvious. Having asked why this isn’t happening I’ve been told ‘because the temp works change all the time its hard to model, we would have to keep re-modelling them’ – I was left pretty amazed by the reply, this is exactly why they need to be modelled! I am a complete convert to BIM for design and see just how beneficial it is to the industry. Having discussed this further with colleagues here I have realised just how unfamiliar any of the engineers are with REVIT or any other form of BIM.

I think for Design and Build to truly be beneficial and the benefits of BIM to be realised the process should be:

Partial Design (initial design) -> build virtually -> resolve issues -> build on site

What I am witnessing is this:

Partial design -> build on site -> identify issues -> re-design -> strip out and rebuild

Has anyone else had a similar experience? Has anyone actually saved time or cost in construction this way? What’s peoples experience on site been of BIM and modelling ahead of live construction?

Old as I am I stopped using anything other than 3D modelling in my practice some years ago

Superficially it looks like a serious cost…and then all the changes start happening….I’ve no idea why engineers haven’t gone ‘all in ‘ on this

I believe it is because ……err…. all the senior ones are nearly as old as I am and haven’t the faintest idea as to how these technologies completely change things

Or maybe they do , but cling to what they know because it gives eternal excuses as to why things went wrong

We have a similar BIM issue on my project. Also a Design & Build contract, the 3D model exists exclusively to identify conflicts between the permanent works, as structures, civils and utilities are being designed by multiple design consultancies under the overarching D&B contract. This model does not take into account any of the temporary works, and is still waiting on some elements of the permanent works as they are packages yet to be designed.

To make matters worse, survey is operating of the separate models submitted from the different design teams in order to have the most up to date information ready to go on-site, rather than the holistic single 3D model, which means conflicts that could be identified in the virtual space, are only identified in the physical space due to the programme overlap with design and construction occurring simultaneously.

While I completely agree with your BIM model:

Partial Design -> build virtually -> resolve issues -> build on site

Maybe we could refine it to include a feedback loop for updated information from site as the project progresses.

My project had the commercial and programme necessity to start the propriety works without a complete design. When works have started on site with incomplete information, the standard is set and processes evolve for identifying conflicts in the physical space and RFI-ing to get the design changed. Maybe we can refine the model to have a better feedback loop so the virtual build has information from the design and the current situation on-site. For instance, all our earthworks plant have GPS models of the design. If this was upgraded from a one-way to two-way feed where the progress of the earthworks and any utilities were fed directly back into the virtual model to identify any further conflicts. This may have prevented the situation I find myself in, about to remove 20,000tn of material and demolish 4.5m of a 12-month-old retaining wall, built in a separate phase of the same project, because the as-build interface was not updated in the central model.

Interesting… the implementation levels for BIM start at the requirement for the model to be federated.

I think that there are so few engineers , with some over arching understanding of processes , that projects are implementing half-baked BiM solutions that may not even cover first base; let alone even attempting to lever some of the real benefits.

The other peculiarity is that it is the grand designs that attract the budgets to have ‘BiM’. These are complex and not the pace to start to see what can be practically achieved.

I’ve no solution other than to say if you know what advantages can be wrought; and you know what can be done ( rather than be at the dubious mercies of specialist technicians) ; then you are in a position to manage implementation

As a point of interest I am joining a meeting with 170 on Tuesday to discuss how to move virtual engineering on with the REs

Great post. Great responses. Very bored with the obvious ignorance in idustry and worse yet within defence engineering. This could have been written ten years ago there has been so little progress. Our profession and industry deserve all of the disrupting that it will get when others decide to move in on the pitch.