What ARE we going to do with partial factors?

Firstly sorry about the Greek – difficult to do in this blog format

This si a live conservation regarding the current re-wrote of PAM 10 Structures for Operations.

The use of PAM 10 must be simple. It must be compliant with current structural design codes .

The current codes combine partial factor and limit state design.

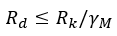

The fundamental equation for ultimate ( failure ) limits states requires that:

the design effect is less that the design resistance.

Crudely we can determine

to get to the design resistance we reduce the characteristic ( usually mean vale to resistance, say , material strength) to ensure that it is statistically unlikely to be lower than the value used in design.

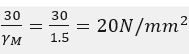

Although not straight-forward it could be envisaged that PAM 10 strength could be expressed as pre-factored so the resistance is determined directly using strength divided by a global gamma M ( for example C30 concrete has a strength of

The partial material factors used would be expressed in the refence documentation together with measures that PQE’s might take to vary risk.

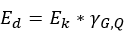

The effects side of the equation is nominally

This implies we enhance actions to ensure that the design values are seldom less than actually applied . This is complicated by three issues:

| Issue | Description | Comment |

| Permanent .v. variable | Different actions are more variable than others. So permanent actions are increased by less than variable ones | Permanent actions are less variable than variable actions |

| Ultimate states .v. service states | Checks for failure Use the limit state in which the actions are factored up and resistance factored down Service checks do not factor actions( generally and use material properties that may or may not be factored | Generally stiffness is factored down for single elements but left at mean for systems ( like floor joists) |

| Multiple variable actions | When a design is checked with, say gravity and wind variable actions the dominant action is enhanced more than the secondary action | It is statistically unlikely that they are simultaneously at the extreme |

Since the narrative for PAM 10 is the management of risk – it seems sensible that some of the partial factor method is represented without having the full complication of full BS EN application.

We therefore would like the consideration of four possible options:

| Option | Resistance | Effect | Comment |

| 1 | Pre factored using recommended | Actions are pre-factored using appropriate gamma G and Q factors (ignoring further partial (psi) factoring of secondary variable actions ) | Resistance would be fairly faithful for design values Pre- factored actions would be difficult when either variable or permanent action dominated in a design . Would generally have to be taken on the high side |

| 2 | Pre factored using recommended | Actions are quoted as in various codes and are to be simply factored using fixed gamma G and Q partial factors ie ignoring further partial factoring ( psi for secondary variable actions ) | Resistance still recognizable Elements of the partial factor risk management seen in simplified action factoring |

| 3 | Resistance is to pre factored down using quoted gamma M and then further factored down using simplified gamma G,Q ( ie all the factoring on the material resistance side) | Actions are used, quoted as in various codes, without any factoring | Resistances would be about a third of the mean value Some conservatism would be embedded to allow for cases of high variable action component Actions used as is So ULS and SLS checks look similar in use |

| 4 | Resistance as quoted in BE EN with recommended partial factors quoted for use to be applied | Actions are quoted as in various codes and are to be simply factored using fixed gamma G and Q partial factors ie ignoring further partial factoring ( psi for secondary variable actions ) | Nearest to BS EN application |

DISCUSS

Hi John I hope you’re keeping well. I thought I’d share my thoughts following your post to open the discussion.

In order to answer the question of what to do with partial factors and PAM 10 we first need to define the purpose of PAM 10 – who is the intended user? Is it (A) Tp Comds / Generalist SNCOs, (B) Clk Wks(C) / MPFs / PQE(E&M), (C) PQE(C) or (D) combinations of A-C.

If (A) then it needs to be as simple as possible and have significant safety factors baked in. If (B) a simplified Eurocode approach would be ideal noting this would leave room for a PQE(C) to design more efficiently to BS EN if required. If (C) what is the point of the rewrite unless it provides an expedient design code for operationally urgent work when there isn’t time for full design to BS EN or PAM 10 provides additional material and loading values not covered in the BS EN (eg wind loading in Afghanistan). If (D) then we probably need to pitch at the lowest level.

I didn’t fully understand the four options presented in the last table because the embedded images don’t work on my phone. What I understood was Option 1 and 2 proposed factoring the actions by different factors, Option 3 applied factors to both the actions and material resistance and Option 4 essentially applies BS EN factors to the actions and material resistance but ignotes the psi factors. I repeat the above because if I’m slightly off I may need to adjust the following comments.

Ultimately I don’t think it matters too much how we apply the partial factors provided PAM 10 makes it clear how they are derived. This is enables PQE(C)s to understand where additional safety had been included in the design and where to focus detailed design work to achieve design efficiency and reduce logistic demand. It also helps with future PAM re-writes and if the BS EN partial factors change.

As for which partial factors are applied I think applying them to both the actions and materials is a wise approach. Tp Comds and Generalist SNCOs will follow the process and not worry too much about why there are factors on both sides of the equation. Clk Wks(C), MPFs and PQE(E&M)s will understand why both sides are factored and wont be put off by it. The advantage of this approach would be twofold: (1) Closer correlation to BS EN so if the design is reworked to BS EN to increase design efficiency it can be done more quickly and results can be compared directly. (2) If locally sourced materials are not meeting the BS EN specifications the partial factors can be adjusted to suit however this can’t be done as easily (or without additional confusion) if PAM 10 lumps both the the action and material partial factors together into a single value. (3) Would there be additional challenges if multiple materials were used eg timber beams and columns onto concrete footings?

So if we were to retain both action and material partial factors how could we simplify the BS EN process? I would suggest we could reduce the load combinations as follows:

STR Checks:

Unfavourable*: 1.35Gk +1.5Qk.1 + 0.75Qk.2

Favourable: 1.0Gk + 0.0Qk

EQU

Unfavourable*: 1.10Gk + 1.5Qk.1 + 0.75Qk.2

Favourable: 0.9Gk + 1.5Qk.1 + 0.75Qk.2

Geo (Unfavourable and Favourable): 1.0Gk +1.3Qk.1 + 0.65Qk.2

SLS: 1.0Gk + 1.0Qk.1 + 0.5Qk.2

*Note STR and EQU unfavourable are very similar. Could take STR as worst case to remove an equation.

For PAM 10, I suggest we round up the partial factors to one decimal place to make it simpler for those who don’t use it very often.

For the material factors I would provide a simple table. The first column would adopt the worst case factor from BS EN for each material type and would be applicable when the supply chain can provide materials that are assured to BS EN requirements. The second column would be for use when materials are not assured ie uncontrolled this would ensure an increased safety factor. The values provided in the column below are illustrative.

Material. Assured. Uncontrolled

RC 1.50 2.00

Rebar 1.15 1.50

Steel 1.25^ 1.50

Timber 1.30 2.00

Masonry 3.00 4.00

^ Note partial factor for connection design.

Again I would propose the factors are simplified further by rounding to one decimal place.

Sorry for the long comment. Hopefully there are some useful thoughts included above. Happy to discuss further.

Brilliant Mark really thoughtful

A few points

You use different values for the secondary variable actions depending on check

I was thinking 0.60Qk.2 because psi 2 is generally around that figure – what doe you think of that as a uniform approach?

You propose1.0Gk as part of the SLS check (and same comment above on psi.2) ; there is an argument that service deflection checks for much of what an RE might actually do might be barely necessary BUT that we might simply take the variable bit as the check with a lower L/Number limit than normal – say L/250 on just the variable?

On material factors I was think that embedding them in pre ordained strengths might save some complexity. ( different factors for steel when reinforcing steel and steel when structural steel, is and example

On reflection, I really like the idea of RE’s own assured v unassured

I’ve stolen it and said that it was all my idea in the first place……!

The one d.p. is very sound we’ll go to 1.2 for assured steel