Archive

Mast Climbing Platforms – A safer, more efficient form of scaffolding?

I am currently working on an SOF Operations Centre on Fort Meade, Maryland for USACE, a new project compared to the usual NSA East Campus site that others may be familiar with. We are currently coming out of the foundation stage and moving into the erection of shear walls and beginning the steel structure placement.

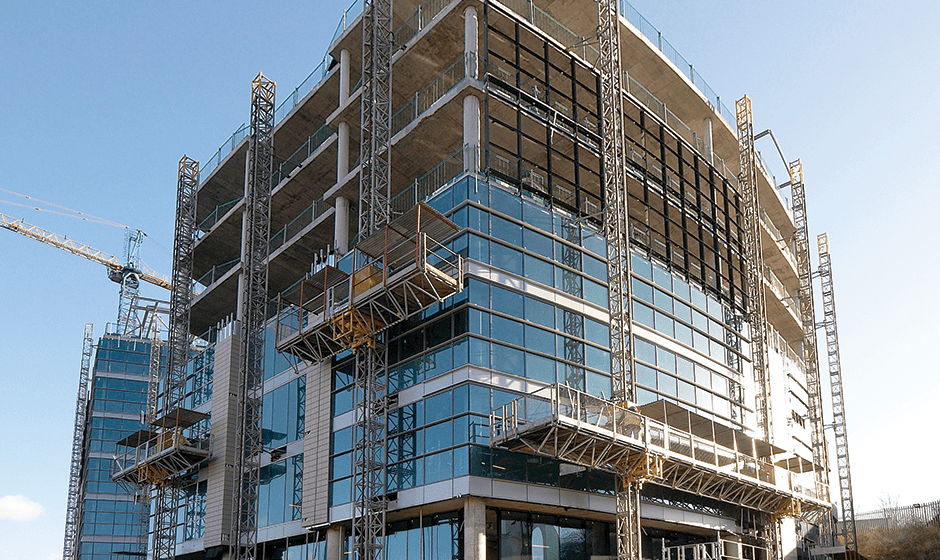

Currently on my site in the US, the masonry sub-contractor is erecting the reinforced three-storey shear walls. They have done this in an exceptional timeframe, currently two weeks ahead of their schedule and one of the primary factors they put this down to is the use of the mast climbers, compared to traditional scaffolding. I have attached several images to this post that show the various setups they can be used in, and examples on sites. For those who have never seen them or not noticed them, they are defined as “A powered device consisting of an elevating working platform mounted on a base or chassis and mast, that when erected is capable of supporting personnel, material, equipment and tools on a deck or platform that is capable of traveling vertically in adjustable increments to reach the desired work level (NYC Building Code 2008).“

I have never encountered this in the UK, so this was a new concept for myself and did some quick digging to see if any further advantages, or disadvantages, that come with using mast climbers over scaffolding:

Mast Climbers Benefits:

- Speedy and Efficient: Mast climbers offer a high level of speed and efficiency as they can be adjusted quickly and easily to the required height, and then quickly moved back down to collect materials, or change shift personnel.

- Increased Productivity: Workers can access a larger work area simultaneously, reducing the need for frequent repositioning, at one point I witnessed at least 15 workers simultaneously working on the masonry structure with little overlap. Combined with the space for worktables, productivity in my opinion seemed much greater compared to the B&Cs of the RE…

- Higher Load-bearing Capacity: Mast climbers can support substantial material, personnel, and other necessary loads, making it feasible to transport to the desired height when compared to scaffolding, which can be an arduous process for materials.

- Quick Setup. The masons had two trained personnel that knew how to construct the mast climbers, they then supervised the rest of the workers and checked all necessary connections and motorised components of the system. For a 20m x 30m tower, the setup of the system took only one day. On the BFT Mastclimbing guide, for a 30m façade, they estimate a setup and strip down of 2 days, compared a scaffolding setup of 16 days, and strip down of 14 days. In terms of project time, this is a significant time saver and easy win for any project manager.

- Footprint. On site, I was surprised to see how little space the mast climbers took up when compared to a traditional scaffold support. Additionally, the storage required was arguably less than a scaffold setup for the same façade, as the mast climbing platforms and extensions are stackable. The Superintendent was clearly a big fan of this and is reluctant to go back to traditional scaffolding after this.

- Safety and Workability. Arguably one of the biggest benefits, mast climbers provide fall protection through the barriers. On the interior side, only harnesses are needed when the interior working wall is less then 3 ft, and then the harnesses are simply clipped to the other guard rail. OSHA has published specific guidance on mast climbers, and incidents do occur, with the most common (dismantling collapse, structural overloading and improper fall protection) all associated with improper training and leadership.

Mast Climbers Drawbacks:

- Initial Capital Investment: This is the main drag of the mast climbers; they have a high initial purchase cost for purchase and installation compared to a traditional scaffold that is very cost effective. They can be rentable, but still at a significant cost. The most recent, unbiased article I could find but mast climbers at approximately three times the cost of scaffolding for the same job (https://www.masonrymagazine.com/blog/2018/03/01/mast-climbers-the-latest-and-greatest/). However, if the amount of vertical masonry is significant on the project, could those costs be saved purely through the time gains if in alignment with the clients aims? Or alternatively, when looking at procurement, could going with the more expensive mason that has one of these at their disposal be a more sensible choice compared to the typical lowest bidder (as occurred on my site)?

- Limited Versatility: When compared to scaffolding, they are more suited for projects with relatively flat facades, as they do not adapt particularly well to irregular surfaces like scaffolding does.

- Regular Maintenance Required: Mast climbers require frequent maintenance when compared to scaffolding, and this must be from a certified, trained individual due to the mechanical components. This is then another cost to consider for the project, and obviously work cannot be conducted whilst maintenance occurs.

I am sure there are many more benefits and disadvantages that I haven’t listed here and please feel free to add to it. Has anyone else on various sites past or present used mast climbers? And if so, were the advantages seen over the long term compared to the short-term positives I’m currently seeing? Are there any scaffolding ‘old-guard’ who are vehemently against the use of mast-climbers?

Quantity Surveying Using Drones

I’m currently in my fourth month of a site attachment with Seymour Whyte Construction (Melbourne, Australia) and involved in the upgrade of a 5km road. Undoubtedly, one of the most utilised (and cost-effective) tools we have at our disposal is the drone. No one reading this will be unfamiliar with the use of drones for aerial imagery capture. However, I wanted to share my experiences of how we have been using this data for engineering specific purposes.

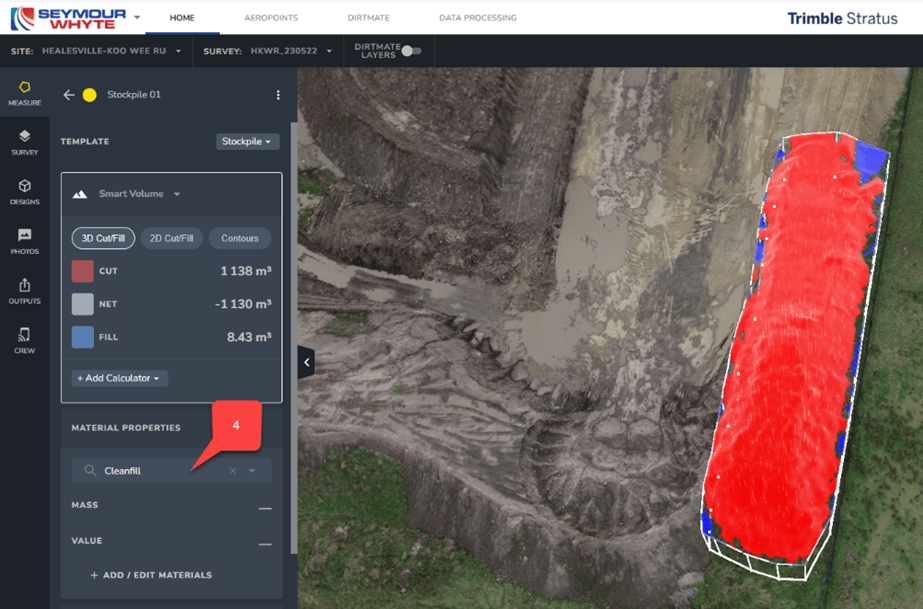

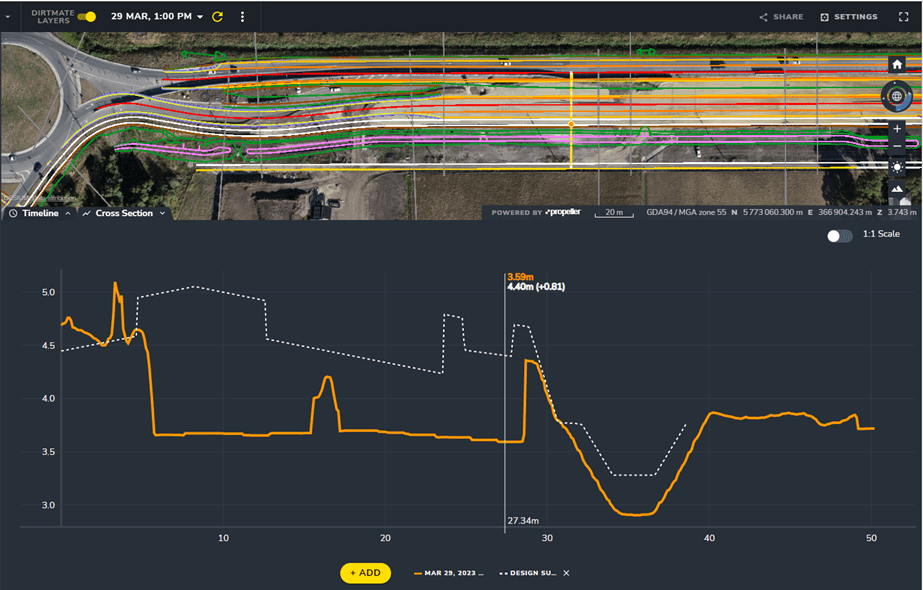

Our software of choice is Propellor (propelleraero.com), used for drone-based data collection, processing, and analysis of earthworks. As frequently as required (usually once a month), our survey manager sends his drone fleet on a pre-determined flight path, covering the entire 5km site within an hour. The data is then uploaded to a cloud service and processed using photogrammetry to create a realistic, fully interactive 3D site model.

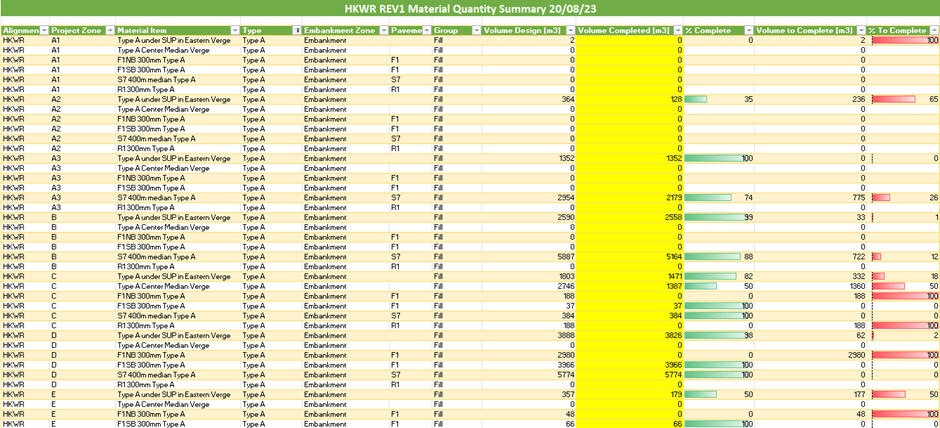

We then use this model for a variety of measurement and management purposes. One of the most useful (and time efficient) processes is the production of quantity take off spreadsheets for end of month financial reviews. The software is able to identify total quantities placed (broken down into specific material types) during the given financial month. We then subtract these quantities from final design quantities to determine what is remaining. Each material type and corresponding construction methodology has a cost rate associated with it (per m3). Once the quantity remaining value is updated, our financial forecast to complete automatically updates.

Coupled with machine tracking systems (Spotlight on DirtMate: How Does it Work? – Propeller (propelleraero.com) we can also use this data for daily progress tracking, cost tracking and material stockpile measurements. With the ability to cut 3D cross sections across the live site model, Propeller can also be used to overlay design drawings on the section, allowing for quick visualisation of material level against FSL.

I wonder if anyone has had other experiences of quantity take off for the purposes of EOM financial reviews? Should our surveyors, and by extension PET students, be learning about some of this technology during Phase 1?

Given that drones are now commonplace in the military context, should we be investigating the potential uses of ME specific drone data processing software? An immediate thought is the benefit of 3-dimensional drone measuring for the purpose of crossing point reconnaissance or for the automation of cut/fill quantities as a planning tool for military earthworks.