Mast Climbing Platforms – A safer, more efficient form of scaffolding?

I am currently working on an SOF Operations Centre on Fort Meade, Maryland for USACE, a new project compared to the usual NSA East Campus site that others may be familiar with. We are currently coming out of the foundation stage and moving into the erection of shear walls and beginning the steel structure placement.

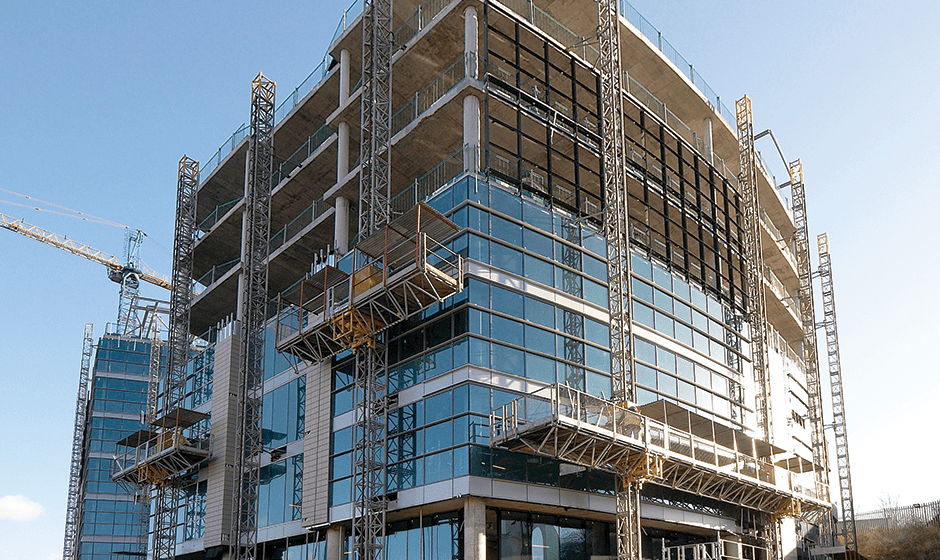

Currently on my site in the US, the masonry sub-contractor is erecting the reinforced three-storey shear walls. They have done this in an exceptional timeframe, currently two weeks ahead of their schedule and one of the primary factors they put this down to is the use of the mast climbers, compared to traditional scaffolding. I have attached several images to this post that show the various setups they can be used in, and examples on sites. For those who have never seen them or not noticed them, they are defined as “A powered device consisting of an elevating working platform mounted on a base or chassis and mast, that when erected is capable of supporting personnel, material, equipment and tools on a deck or platform that is capable of traveling vertically in adjustable increments to reach the desired work level (NYC Building Code 2008).“

I have never encountered this in the UK, so this was a new concept for myself and did some quick digging to see if any further advantages, or disadvantages, that come with using mast climbers over scaffolding:

Mast Climbers Benefits:

- Speedy and Efficient: Mast climbers offer a high level of speed and efficiency as they can be adjusted quickly and easily to the required height, and then quickly moved back down to collect materials, or change shift personnel.

- Increased Productivity: Workers can access a larger work area simultaneously, reducing the need for frequent repositioning, at one point I witnessed at least 15 workers simultaneously working on the masonry structure with little overlap. Combined with the space for worktables, productivity in my opinion seemed much greater compared to the B&Cs of the RE…

- Higher Load-bearing Capacity: Mast climbers can support substantial material, personnel, and other necessary loads, making it feasible to transport to the desired height when compared to scaffolding, which can be an arduous process for materials.

- Quick Setup. The masons had two trained personnel that knew how to construct the mast climbers, they then supervised the rest of the workers and checked all necessary connections and motorised components of the system. For a 20m x 30m tower, the setup of the system took only one day. On the BFT Mastclimbing guide, for a 30m façade, they estimate a setup and strip down of 2 days, compared a scaffolding setup of 16 days, and strip down of 14 days. In terms of project time, this is a significant time saver and easy win for any project manager.

- Footprint. On site, I was surprised to see how little space the mast climbers took up when compared to a traditional scaffold support. Additionally, the storage required was arguably less than a scaffold setup for the same façade, as the mast climbing platforms and extensions are stackable. The Superintendent was clearly a big fan of this and is reluctant to go back to traditional scaffolding after this.

- Safety and Workability. Arguably one of the biggest benefits, mast climbers provide fall protection through the barriers. On the interior side, only harnesses are needed when the interior working wall is less then 3 ft, and then the harnesses are simply clipped to the other guard rail. OSHA has published specific guidance on mast climbers, and incidents do occur, with the most common (dismantling collapse, structural overloading and improper fall protection) all associated with improper training and leadership.

Mast Climbers Drawbacks:

- Initial Capital Investment: This is the main drag of the mast climbers; they have a high initial purchase cost for purchase and installation compared to a traditional scaffold that is very cost effective. They can be rentable, but still at a significant cost. The most recent, unbiased article I could find but mast climbers at approximately three times the cost of scaffolding for the same job (https://www.masonrymagazine.com/blog/2018/03/01/mast-climbers-the-latest-and-greatest/). However, if the amount of vertical masonry is significant on the project, could those costs be saved purely through the time gains if in alignment with the clients aims? Or alternatively, when looking at procurement, could going with the more expensive mason that has one of these at their disposal be a more sensible choice compared to the typical lowest bidder (as occurred on my site)?

- Limited Versatility: When compared to scaffolding, they are more suited for projects with relatively flat facades, as they do not adapt particularly well to irregular surfaces like scaffolding does.

- Regular Maintenance Required: Mast climbers require frequent maintenance when compared to scaffolding, and this must be from a certified, trained individual due to the mechanical components. This is then another cost to consider for the project, and obviously work cannot be conducted whilst maintenance occurs.

I am sure there are many more benefits and disadvantages that I haven’t listed here and please feel free to add to it. Has anyone else on various sites past or present used mast climbers? And if so, were the advantages seen over the long term compared to the short-term positives I’m currently seeing? Are there any scaffolding ‘old-guard’ who are vehemently against the use of mast-climbers?

Never seen these before and can’t say many of the other engineers on my site

1. How does the system fare with regard to the temporary works side of things? Especially if it starts to face significantly unbalanced loading across the top.

2. As you mention these cost a few dollars to invest in – is there a pressure to make maximum use and could suffer from horrendous standing charges if predecessor works are delayed or sites have to shut for periods of time due to say, a worldwide pandemic?

3. Is the training burden fairly significant fore these? Scaffolding can be taught, stored and maintained fairly cheaply but if your one Mast Climber is off site does that shut down its use?

1. The loads are all transferred through the mast of the climbers, so no loads are actually applied to any other temporary works. The only time it’s linked to the permanent or a temporary structure is for ties when elevated to significant heights (every 6-9m). For the uneven loading, the mast climber we have on site is a twin mast that can lift a maximum of 6000lbs (~2700kg in normal units) at full height (22m). This reduces significantly using a single mast system, but this is the maximum load that can be applied anywhere on the platform at a given time, so I’m assuming is worked out from the maximum moment at the furthest point from the centre. However, if you google mast climber incidents, overloading is one of the most common causes of failure, so training is still essential.

2. The sub-contractor bought there’s from a supplier and said they have made the money back from the amount of time it saved on numerous sites. I can imagine renting is extremely costly due to any delays. I wouldn’t be surprised if predecessor works were delayed the sub-contractor would try to put these delay costs onto the principal contractor. For our site, the masons didn’t start work until they got the thumbs up that the foundations and utilities they were building on were finalised and inspected. Otherwise they might have ran into that severe delay cost you mentioned.

3. I thought the same, but the operator training is an one day long at most from what I was told. I was shown the controls and how it fit together, genuinely surprised how simple the controls were. Assembly was more akin to giant Lego with the assistance of a forklift, the only difficult part was the electronical components where the trained individuals were needed. The subbie keeps 3 trained personnel on their staff at all times so a competent individual is there to assemble and deal with any mechanical issues. I guess it’s similar to us with vehicle drivers in Sqns, we have to balance and manage competent personnel to ensure we can get vehicles out the door, if the subbie doesn’t have trained personnel there, that’s their money loss and they’ll avoid that at all costs.

Looks pretty interesting but very limiting with current tech, particularly when the imaginative Architects get involved; something I am sure Jamie Sloan would attest to.

It is a very similar concept to the jump form I have seen in wide use around the Brisbane and will be used on my site once the groundworks and basement are complete. Basically allows the core of the structure to be erected, reach sufficient strength and so the slabs can quickly follow. Improves the efficiency of the build and reduces crane requirements.

Seems like these are proprietary systems that also allow us to reduce the risk of temporary works and the associated time/Cost/Quality of design, design checks and high frequency of H&S inspections associated, particularly with scaffold. In the time I have been in Australia, the vast majority of industry safety notices I have read have been to do with scaffold being incorrectly erected or used. in most cases, these are both attributed to human error that would be reduced or eliminated through the proprietary system. If this becomes more architecturally friendly, it will definitely reduce the incidents seen across the industry.

Interested to lok down and see the foundation set up for this.