Archive

Structural Failings on Site – Welch Elementary School

Working with USACE, I get the opportunity to visit different sites to broaden my experience and see various forms of engineering at work. I recently visited the Major George S. Welch Elementary School on Dover Air Force Base, Delaware and was surprised at how badly this construction project had gone.

Construction began in June 2019, with the aim of being open for the 2021 school year in Sept/Oct. With it now being close to 2024, it’s safe to say that the $48 million project has failed to deliver and current estimates put it at a finish date of late 2025/early 2026. The current situation is that no future construction is ongoing, and the principal contractor is going through a corrective process for all issues currently found on site, (estimated over 10,000 deficiencies so far). If they fail to correct these issues within a timeframe that USACE is determining, the contract will be terminated and a re-issuing process will have to be established, a costly and timely exercise that they want to avoid. There have been numerous failings throughout all levels for both USACE as a Govt body ensuring successful delivery on behalf of the client, and the principal contractor, Dobco, Inc. Whilst the project and programme management side have had plenty of issues, I was more interested in the ongoing structural failings of the current shell, as I’d heard that a Special Inspector deemed the site completely unsafe for any future work.

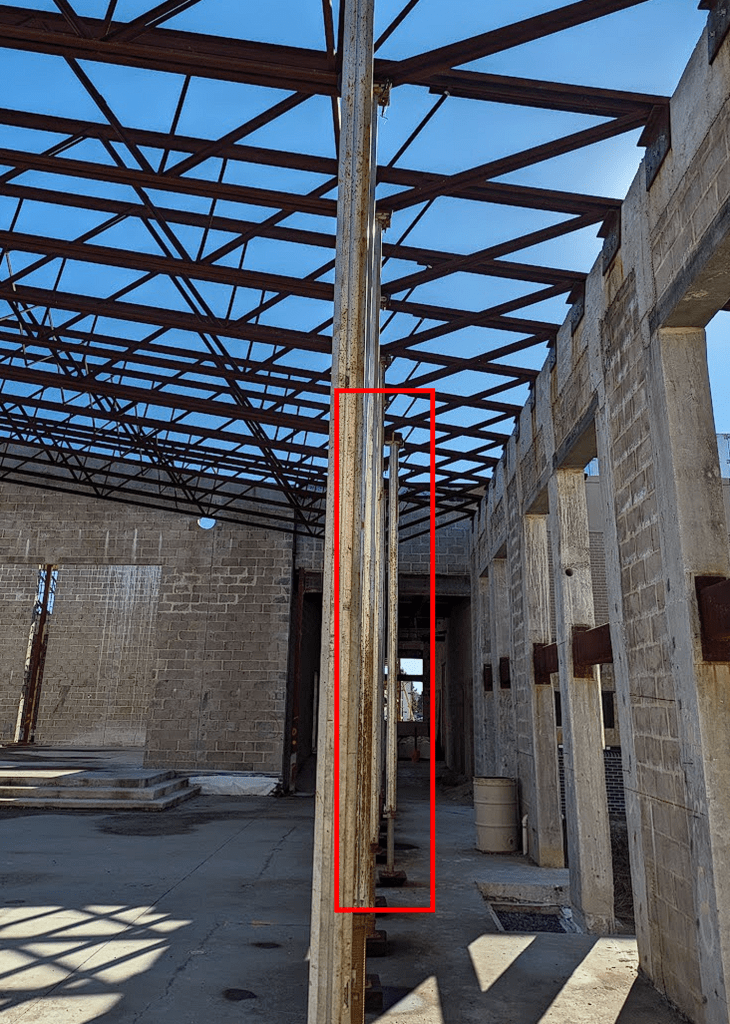

Some of the structural failings were alarming, and I was surprised that they had reached this level with no remediation at all. Unsupported structures, corroded trusses and failed loaded columns was what was immediately visible going into the site. A picture below shows some of the columns that seemed to just have forgotten to have concrete placed at the base? And then to top of it, the contractor failed to provide adequate drainage to the area, resulting in prolonged flooding around the exposed rebar and therefore significant corrosion. I don’t understand this was not spotted on site for such a long period, or if seen, didn’t have any concerns that a concrete column base didn’t have actual concrete in it.

Further up from that column was an unsupported horizontal steel element, what appears to be designed as a restraint for the column’s slenderness but isn’t actually attached. Speaking to the PE there, it seems that the contractor must have sent the fabrication details to the steel supplier, but upon receiving the reduced size element, they just then decided to install it rather than thinking this doesn’t appear to be right. Instead of removing it and fitting it a correctly sized element, their solution was to prop it with timber and concrete the end of the steel beam into the column, clearly without the reinforcement then fitting into the column as designed. A mind-blowing piece of engineering.

There were numerous other structural issues; mis-sized fabricated truss roof elements, meaning the column was out of alignment, changing the load paths and altering the rooms design from originally intended (picture below). Significant cracks on every concrete slab (below), of nearly 10mm wide in some areas, well beyond an allowable tolerance, filled with water, perfect for the upcoming freeze-thaw weather.

I’d often heard about some contractors winging it on site with little understanding of the engineering they are constructing, and a disregard for personal and structural safety, but I didn’t think I would witness such significant failures in person. A lot to gain experience wise, but I can imagine working or overseeing such a site must be an absolute nightmare. Has anyone else experienced such disregard for proper methodology? And if so, is there any likelihood of the contractor redeeming themselves, or is it better to pull the plug on them earlier rather than later?

If anyone is further interested in this site, I can provide more information about the project delivery failures, and I’m due to visit again in January so can see if the site has advanced any further, or most likely, completely collapsed.

Noise, Dust and Vibration Monitoring.

I am intending for this post to be both informative and potentially open the floor to discussion on the subject. It was something we learned about briefly on Phase 1 but it was not something I expected to see on site in the way I have so keen to know others experiences.

I am currently working on a John Holland site in the Brisbane city centre, called Waterfront Brisbane. The project involves demolition of what used to be called Eagle Street Pier and the construction of a retail precinct alongside commercial-residential towers. By the nature of the site location, it is in close proximity to both the workforce and the public, so there has been significant emphasis on Noise, Dust and Vibration (NDV) management, for which I have had responsibility. I have been doing so in accordance with the NDV management Plan for the project. This has highlighted the importance of stakeholder engagement and NDV management to me in such a congested environment or where there are risks to workforce. Below is a link to the overview of the project:

Twitter/X Report on The Project – Photo from a neighbouring property.

Footage of a report from YouTube

The main concern thus far has been on silica dust management for the workforce and dust management and the respective stakeholder engagement around this. Silica is often referred to as the “new asbestos”, and it’s important to take steps to protect workers and the public from exposure. On this site, we’re using a combination of NDV monitors that key into a live online interface that allows live and historical reporting. This has also been a significant point of concern due to the close proximity of restaurants and cafes on the Brisbane river.

One of the things I’ve been looking into is the impact of moisture on dust monitors that don’t control moisture. This arose from the fact that our dust monitors, and the live reporting interface, were sending alerts for significant dust level exceedances which meant that on the face of things, we were exceeding the Workplace Health and Safety thresholds for dust. In researching the technology used for the monitors, I worked out that they use a laser that registers particles and their size based on scattering of the sample air. This meant that the use of dust suppression on the demolition site, predominantly through water misting cannons, was leading to false readings. This can also be an issue in very high humidity conditions that can occur naturally. If moisture gets into the dust monitor, it can cause false readings or damage the equipment.

I’m interested to hear from other experiences in the UK and Australia about their exposure to this:

Is this something other placements have had to deal with?

Has anyone had any Australian or UK based NDV management experience?

Do any past PET students see any of this NDV management being implemented on RE construction projects (Dust must be an issue on some of the projects/past projects)?

Has anyone else had to manage stakeholder concerns about NDV?

I suspect there is less of an issue with this in the UK during most of the year due to frequent rainfall acting to supress the dust but I imagine noise and vibration would still be a big concern. It seems like the standards set here in Australia are very similar to those in the UK and Europe e.g. daily dust limits, noise exposure limits, vibration exposure for buildings, the tolerances for heritage buildings etc

Another thing I’ve learned on this project is the importance of having the live data available. This allows us to quickly identify any areas where levels are too high, or are approaching an exceedance, and take steps to address the problem.

I also believe that it’s important to use a heated inlet for a laser-based dust monitor. This helps to prevent condensation from forming on the lens, which can interfere with the readings. I have included some links to images of monitors with and without heated inlets to give some context of the equipment I am referring to.

Airmet Heated Inlet

SiteHive Combined Noise and Dust

As the project progresses from the demolition of the superstructure onto the piling stage (commenced last week), vibration and noise will become serious stakeholder concerns for us to manage. Managing an exceedance in the vibration would look like works stopping and a structural assessment being conducted, something that is undesirable for several reasons.

I will attempt to get some photos uploaded to give more context on the project interface with stakeholders but I think this is a start in getting the conversation rolling.

Working in the Trenches – OSHA vs HSE

I have had a few difficulties on site when it comes to workers operating in excavations and trenches whilst on attachment in the US. The areas the workers have been in often have slopes that appear near vertical in their cut and what I could class as significant in height. When I have questioned this to the H&S Manager on site, they have stated that support is only required when the excavation or trench is 5 foot (1.5 metres) or more. Access and egress points only need to be placed for 4 foot or more, but still no support is required at this depth. Alternatively, they can be cut back with a step, or at a 45 degree angle dependant on the ground, but this is just as difficult to enforce on site as well. The problem is exacerbated by the following:

- The areas they are often working in is a mixture of a very loose sandy material above a consolidated clay layer; walking near the excavation can often result in slips of the material then falling into the trench.

- Spoil heaps are placed nearby to any excavation, OSHA does not specify a minimum distance, just a ‘safe distance’ judged by a competent person. I’ve often seen this for a spoil heap up to 3m high, less than 2 metres away from a trench. When the competent person is the H&S Manager who classifies 5 foot of unsupported excavation as safe, you can imagine their idea of a ‘safe distance’ when it comes to spoil heaps.

The problem I seem to be having is that if I comment or ask for a trench to be supported, or spoil moved back, I’m simply met with a response that this is per the OSHA requirements. When compared to HSE, they removed the previous 1.2 metre (4 foot) rules as excavation and trench support depends on the ground conditions and other risks. I wish this was the case for OSHA but I’m at a bit of a brick wall when it comes to the H&S Manager. I’ve passed up my concerns to the principal contractor and to my CoC at USACE, but met with the same thing; as long as they are within OSHA guidance the H&S Manager is technically correct. I don’t know about you, but I certainly don’t get the warm fuzzy feeling going into a 5-foot unsupported trench with loose material surrounding me, especially if I’m on my hands and knees working on utilities.

To put it into a statistical perspective, OSHA reported in 2022 that 39 workers were killed in the construction due to trench and excavation collapse (OSHA, 2023). In the UK for the same year, across all worker industries, 12 people were killed by collapses or being trapped (HSE, 2023). This may not even be related to excavations, but no deeper data can be found, but I think it’s easy to conclude that excavation related fatalities are rampant across the US compared to the UK.

Has anyone else encountered something like this before or could offer any professional advice on how to move forward?

Sources: OSHA Excavation Deaths Statistics 2022, more information can be found at https://www.safetyandhealthmagazine.com/articles/23703-trenching-and-excavation?page=1.

HSE Work-related fatal injuries in Great Britain 2022/23, available at https://www.hse.gov.uk/statistics/fatals.htm.

Smiling Assassin or Shrewd Business Practice?

After several months and now experience of several sub-contractors (and then sub-sub, sub-sub-sub ad infinitum…) I thought to reflect on a few observations I’ve found from the world of civilian business practice. As graduates of the esteemed RMA Sandhurst , we live by the Values and Standards, drilled into us from day one to the point that personality is surgically removed and replaced with a code of conduct – I find it strange that it seems such a code of honour can be more negotiable in industry.

Now to be clear, I have not witnessed anything outright illegal or amoral but perhaps a few instances of “collaboration” which appears in conflict of the NEC approach where one party may mislead another through varying versions of the same truths, revealed at carefully stage managed points in time. This has come at increased surprise to me as any contractor on site must be, as a minimum BPSS vetted if not SC, and so come withs a modicum of implied trustworthiness.

An example –

During Client inspection of concreting works where tolerances were tight (-0/+5mm on plan). It was known by a subbie (and sub-subbie) that they were just over, by 1mm. The decision was made, through some implied comms and impressive framing of the problem that we were all better off if the client was led to believe that the slab was on tolerance and the offending non-conformity was shaved off by the night shift to achieve tolerance – as if it had never happened. My question was this;

“Why not declare the non-conformity in good faith but also how you plan to remediate and keep the client happy that we’re a diligent contractor?” (Or words to that effect…)

The answer, whilst simple, seemed almost a lie of omission;

“Paperwork”

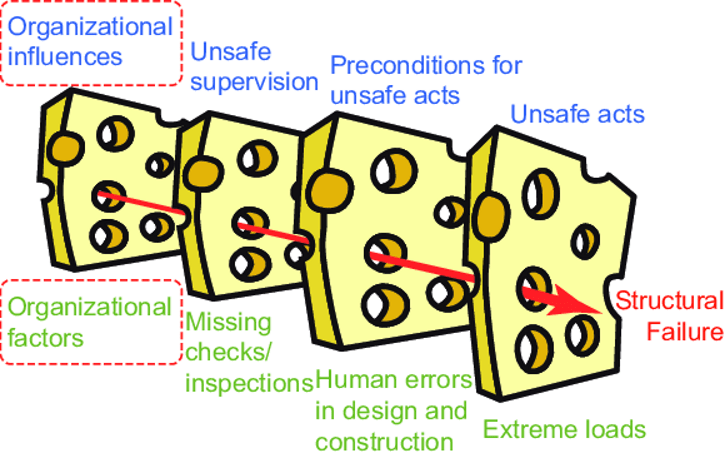

I can see the pragmatism of such an approach where hours have been saved by removing the need to submit TQs or NCRs and the bureaucratic process therein. Does integrity have a price? My gut tells me no – one must always do right by the plan and contract, less you end up tangled in a web of lies. Apart from patting myself on the back for the DS answer, it did raise another thought – at the root of this, is it not a slippery slope where there may be other dangers lying beneath? Errors compounding errors (think of the Swiss cheese risk model). Thoughts that were shrugged off by the majority of project staff.

Perhaps I have been lost in the woods too long and suffer from institutionalised naivety but I wonder if others have experienced similar?

(Image From: Ren, Xin & Terwel, Karel & Nikolic, Igor & Gelder, P.H.A.J.M.. (2019). An Agent-based Model to Evaluate Influences on Structural Reliability by Human and Organizational Factors.

Conference: Proceedings of the 29th European Safety and Reliability Conference