Structural Failings on Site – Welch Elementary School

Working with USACE, I get the opportunity to visit different sites to broaden my experience and see various forms of engineering at work. I recently visited the Major George S. Welch Elementary School on Dover Air Force Base, Delaware and was surprised at how badly this construction project had gone.

Construction began in June 2019, with the aim of being open for the 2021 school year in Sept/Oct. With it now being close to 2024, it’s safe to say that the $48 million project has failed to deliver and current estimates put it at a finish date of late 2025/early 2026. The current situation is that no future construction is ongoing, and the principal contractor is going through a corrective process for all issues currently found on site, (estimated over 10,000 deficiencies so far). If they fail to correct these issues within a timeframe that USACE is determining, the contract will be terminated and a re-issuing process will have to be established, a costly and timely exercise that they want to avoid. There have been numerous failings throughout all levels for both USACE as a Govt body ensuring successful delivery on behalf of the client, and the principal contractor, Dobco, Inc. Whilst the project and programme management side have had plenty of issues, I was more interested in the ongoing structural failings of the current shell, as I’d heard that a Special Inspector deemed the site completely unsafe for any future work.

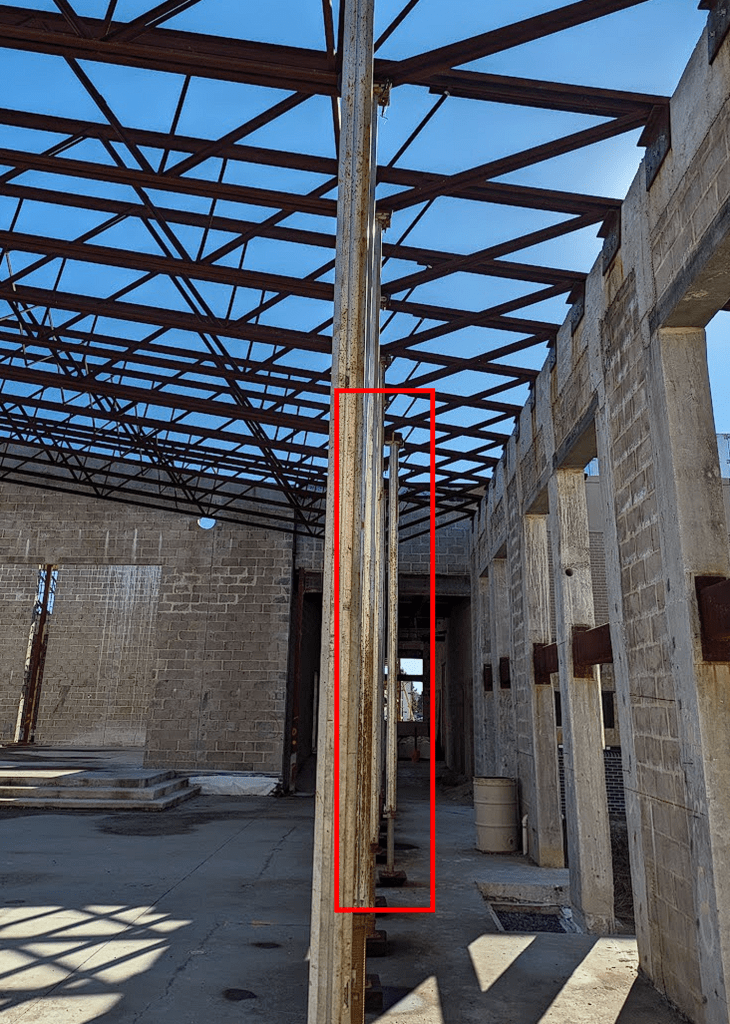

Some of the structural failings were alarming, and I was surprised that they had reached this level with no remediation at all. Unsupported structures, corroded trusses and failed loaded columns was what was immediately visible going into the site. A picture below shows some of the columns that seemed to just have forgotten to have concrete placed at the base? And then to top of it, the contractor failed to provide adequate drainage to the area, resulting in prolonged flooding around the exposed rebar and therefore significant corrosion. I don’t understand this was not spotted on site for such a long period, or if seen, didn’t have any concerns that a concrete column base didn’t have actual concrete in it.

Further up from that column was an unsupported horizontal steel element, what appears to be designed as a restraint for the column’s slenderness but isn’t actually attached. Speaking to the PE there, it seems that the contractor must have sent the fabrication details to the steel supplier, but upon receiving the reduced size element, they just then decided to install it rather than thinking this doesn’t appear to be right. Instead of removing it and fitting it a correctly sized element, their solution was to prop it with timber and concrete the end of the steel beam into the column, clearly without the reinforcement then fitting into the column as designed. A mind-blowing piece of engineering.

There were numerous other structural issues; mis-sized fabricated truss roof elements, meaning the column was out of alignment, changing the load paths and altering the rooms design from originally intended (picture below). Significant cracks on every concrete slab (below), of nearly 10mm wide in some areas, well beyond an allowable tolerance, filled with water, perfect for the upcoming freeze-thaw weather.

I’d often heard about some contractors winging it on site with little understanding of the engineering they are constructing, and a disregard for personal and structural safety, but I didn’t think I would witness such significant failures in person. A lot to gain experience wise, but I can imagine working or overseeing such a site must be an absolute nightmare. Has anyone else experienced such disregard for proper methodology? And if so, is there any likelihood of the contractor redeeming themselves, or is it better to pull the plug on them earlier rather than later?

If anyone is further interested in this site, I can provide more information about the project delivery failures, and I’m due to visit again in January so can see if the site has advanced any further, or most likely, completely collapsed.

Without being “that guy” the only place I’ve seen anything resembling this was overseas in developing, third world countrieI’s – and then there was the presence of mind to query what are some fairly obvious holes that shouldn’t be there (and then pack it out with copious amounts of concrete).

I’m curious to understand what was the ITP schedule or at least what the contractual obligations were for QA and inspections from the Client and PC? Does the US operate on a Quality Management system like the ISO9001? And if so, does the PC have it? Probably not for much longer though….

This does raise an alarming question of the quality of work installed – especially if its to be an elementary school, I would be in serious doubt of the quality of any of the concrete mixes for example. Have they actually achieved design strength? Is it mixed as per design spec or has it it been backfilled to make up volume with rocks/bricks/Makita batteries etc.

I’d be interested to know what the PC’s answer was to being shown some obvious and almost criminal negligence on their part!

There is a lengthy QA/QC process, the principal contractor is required to have a QC manager alongside a third party of Special Inspectors who perform the majority of the QA on behalf of the contractor. Then overseeing all of this is USACE with a QA team of Project Engineers. I have no idea how all of this slipped through the cracks, clearly the faults got so bad that the QA stopped doing their jobs on all parts.

The concrete was being tested as well with core samples, unsurprisingly the concrete used for some the columns and walls that was specified as 4000 or 5000 psi (27/35 MPa) turned out to be 3000 psi mix (20 MPa).

It’s a great case study for everything that went wrong, the rumour I overheard was that the project on the USACE side was managed by a Army Captain who had zero engineering experience or background. Guess it shows that the bluffing it in the Army can only take you so far in certain jobs.

I think the thing to remeber is that, even as a PQE, we all have zero experience of many aspects of our profession. What sets us apart is our ability to identify the gap, plan to close it through research and developmental activities, such as site visits and reading blogs in order to learn from others, and then approaching manageing the risks with our eyes and ears open and a readiness to confer openly.

These photos provided a throwback to my rural childhood – witnessing cash poor asset rich farmers stingily constructing agricultural buildings out of any old material they can round up, rusted or otherwise. That alone rings alarm bells about the fact this is destined to become an elementary school.

In answer to your question, I have seen a different aspect to methodology disregard. With every new ITP, there seems to come an increased quality expectation due to technology growth on site (GPS excavators, assisted steering on plant, intelligent compaction, 3D survey, laser cutting etc.). In some instances, the tolerances are now virtually impossible to achieve. In an attempt to avoid endless NCR’s, aided by a general acceptance that some of the requirements are overkill, on-site surveyors and quality testers are becoming very proficient at ‘cheating the system’ to facilitate ITP sign off for engineers; clearly dangerous territory to stray in to and unfortunately further solidifies false claims from quality managers and clients that ‘we achieved it on the previous job’ when challenged.

The stock PC response to over specification and the claim “we achieved it on the previous job” should be “we can do so on this one at a price, but you pay for quality and you don’t need this level of quality to deliver the product you want. We can save you a lot of time and money without any reduction to your quality standard.”

Following up to your original article (dated 10.30.23). What’s the status of the school at of today’s date 09.30.25?? Was the new construction completed or demolished?