Archive

More Trains More Services – Next Rail

For my Phase 2 placement, I am working as a Project Engineer for John Holland supporting the development of rail infrastructure in Sydney. This is as part of the More Trains More Services (MTMS) multi-billion-dollar programme and is focused on power upgrades, signalling, stabling facilities and station platform upgrades. This will deliver trains every two and a half minutes in peak hours on key corridors.

Key Project Stakeholders

John Holland Group (the Principal Contractor) is working in partnership with Transport for New South Wales (the Client) and Jacobs Engineering Group (the Principal Designer). The three groups have been combined as “Next Rail” and are described as an Incentivised Delivery Entity (IDE), with the intent of sharing any benefits/losses on completion of the programme. Additionally, Sydney Trains (a department of TfNSW) is the Operator/Maintainer and take a keen interest in works that are done. This partnership has created a complicated hierarchy and has already led to stakeholder engagement and expectation management being a key part of my role.

The Delivery Commissioning and Handover Team.

My initial work has largely consisted of closing snags and overseeing commissioning work. For example:

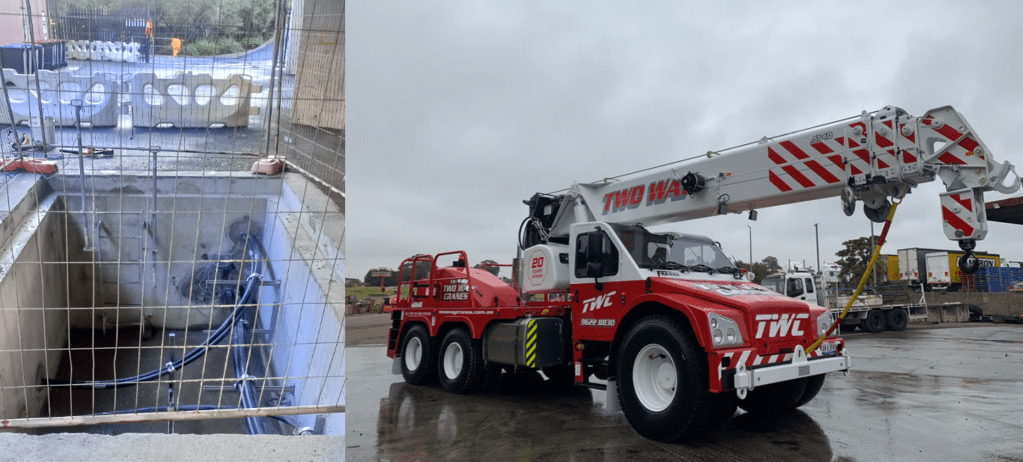

- Overseeing the commissioning of 11kV feeder cables from a new substation (to increase supply) and removing redundant ones. This was done during the early morning when electric trains were not running. It required use of a Franna crane to lift a cable pit cover (after the cables had been isolated) due to the overhead restrictions. This was a piece of equipment I had not seen before and was able to lift the 5.5ton lid with the boom in the lowered position (shown below).

- Replacement of sections of overhead wiring and strengthening overhead gantries to resist torsion. This was heavily delayed due to power leakage between lines – it is often difficult to isolate lines to below the 50V required for work to be allowed to take place. This causes significant delays and immense cost to Next Rail despite being out of their control. Other issues have been the need to vermin proof signalling boxes to prevent chewed cables!

Wolli Creek Demolition Task

The main task I am working towards is the demolition of some redundant assets and their replacement with an access road/long vehicle turning area. This will include importing fill from another site to raise the existing ground level and there is current discussion as to whether this can be ‘contaminated material’. The site is situated at a rail junction, between two rail corridors and an area of residential high-rise flats.

Key risks noted so far have been:

- Contaminated Ground. Rail corridors are often built on landfill and due to oil and waste leaks from locomotives, almost all the sites have been found to have contaminated ground during excavation (even asbestos panels encased in concrete). This has led to significant costs and delays that were not considered in the planning stages.

- Underground Services. As well as 1500V DC overhead cables, the site is surrounded by live underground services and a high-pressure gas main. In Australia, “positive identification” and “positive location” is required, meaning that any excavation is likely to require a suction excavator.