Archive

Reinforced Timber in Construction

Having written a TMR on Low Carbon Concrete and the difficulties of specifying it on site, I was invited to attend a MECLA (Materials and Embodied Carbon Leaders’ Alliance) event at the University of New South Wales (UNSW). MECLA are an Australian Government think-tank, combining industry, academic and government professionals, and as part of the conference were reviewing the latest research at the University. Part of this, that I thought would be interesting to the wider course, was research into reinforced timber using prefabricated composite elements by Prof Hamid Valipour. The intent is that these can be used as structural members in mid-rise structures (4-5 storeys).

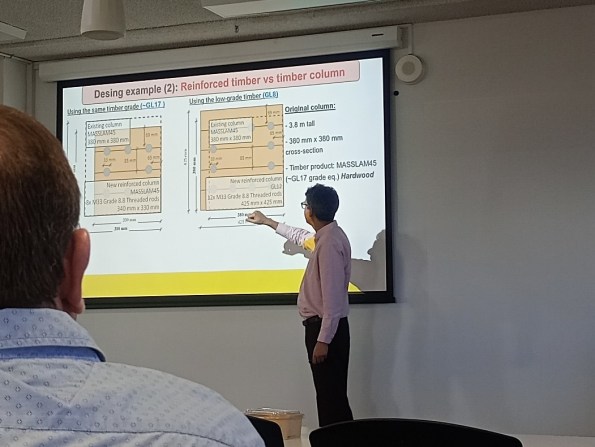

One benefit of the research was that a timber member could be replaced with the same quality timber containing steel reinforcing, leading to a significant reduction in required cross-section to resist load. However, the main sustainability benefit was that high quality timber could be replaced with low-grade timber, such as Douglas Fir. When reinforced with steel rebar, this low-grade timber would still have a smaller cross-section than significantly higher quality timber used on its own and allow lower quality, faster growing timber to be used for structural purposes.

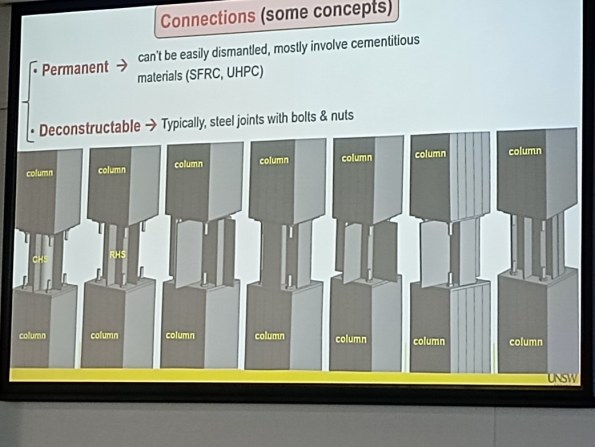

Connections could be de-constructable, created using steel plates (as shown above). These are bolted onto the end of the threaded rebar (the same bars as used in concrete) that protruded from the timber members, allowing the joints and structure to be dismantled at the end of its life. Alternatively, for more permanent structures ultra-high strength concrete, that cured within 48hrs to over 100MPa, was used to connect members, allowing the structure to be load bearing and built in a short period of time, as well as protecting joints from fire.

The members themselves are created form beams of glue-laminated timber with grooves cut into them using a router table. The steel reinforcement bar is then placed inside and a glue is poured into the joints to bond the bars and timbers together. These are then clamped and held in compression for 48hrs. Not only are the members very strong, but due to the steel being encased inside the timber, they also have a high resistance to fire.

The rebar can either be threaded to be a male or female end as required. They can then be rapidly assembled on site.

Using this method, beams and columns have been tested with some being left for up to two years to measure creep and verify the quality of the bonds. Beams were also tested for vibration and deflection. It was found that once beam spans were limited to 8.5-9m before vibration and deflection became the constraining factors.

The beams have also been tested as a composite in conjunction with concrete slabs to produce floors. One key consideration when used in this manner was that a membrane needed to be placed between the concrete and timber when the concrete was poured. This was because the concrete would chemically attack the timber, reducing strength by around 1/3.

So far, the project has been a resounding success and Prof Valipour is trying to ensure that all of these members meet existing timber codes to allow a rapid transition into use. However, he did state that it will come down to design consultants to hold the risk of utilising them in design and identifying whether they can meet required design lives (the irony was not lost on me). This further demonstrates the difficulty of utilising new research and techniques in industry but may be something we are able to work with in the near future.

Are your briefings understood?

We had an incident on site last week where a 9 tonne dumper rolled over. The driver was OK, he escaped with a broken wrist and collar bone. The initial, unofficial, assessment is that this was a simple case of driver error as it appears that he reversed off of the haul road. However, as often seems to be the case in situations like this, there is always more than meets the eye. It turns out that the supervisor has only just joined the job and was authorised as a ‘competent person’ by the project director just 6 days before the incident. The usual foreman was off on holiday and was not providing the same amount of supervision as is normally applied in the area. (I should stress that this is routine business; if a foreman or supervisor is away on holiday, their workload is often shared between others of the same grade.) Finally, had the dumper driver understood the daily briefing?

Our labour (ground workers, excavator operators, multi-skilled operators etc) tend not to have English as their first language. Of the 19 gangs we have on site, only 3 have a supervisor where English is their first language. Adding to this complexity is the fact that the gangs are not made up of people who speak a common language, the language used on site to communicate is English. But how much does the Romanian ground worker understand the brief given by his Indian supervisor? What about the Pakistani dumper driver receiving instructions over the radio from his Albanian supervisor? Not only are we communicating in a language foreign to everyone, the language that is being used to communicate between them is being delivered by someone else who does not always have a good grasp of English.

This begs 2 questions; firstly, where is the British workforce? A ground worker earns £22/hour and many of them work 11 hours a day for 6 days a week. You do the maths, but this is a lucrative job for an unskilled labourer. The foreman are mainly from a British background, but that won’t be true for much longer if there is no one coming through.

Secondly, and more importantly, should we be adjusting our method of communication to ensure that everyone understands daily briefings? Should we be asking our supervisors to use a translating software so that the brief is input accurately by whoever is giving it and clearly understood by the one receiving it? Surely our responsibility is to ensure that everyone works safely and if we have to make allowances by changing our communication style, then we should be doing it!

Does anyone else have similar challenges? Has anyone already overcome this problem and is already doing briefings using a translating software?