Archive

Diffuser Selection

Initial task

As mentioned last week I’m currently being asked to look at two projects, a Biopharm for GlaxoSmith Kline (GSK) and the re-fit of some steam plant at the London School of Hygiene and Tropical Medicine. I get the impression that Bryden Wood were hoping to initially fill my time with the steam plant project, however, I won’t be able to get involved with this until Wed at the earliest. Therefore I’m having a bit of a slow start, which is no bad thing after the last few months on site. My task to date has been to look at possible diffuser solutions (air supply) in a number of rooms in the Biopharm facility, which will ultimately feed into the specification for the main contractor. I’ll start with a few paragraphs stolen from the GSK website:

Firstly what are Biopharmaceuticals?

Biopharmaceutical products are medicines engineered by scientists and manufactured by living organisms to treat specific ailments. Biopharmaceuticals often target specific cellular functions and tend to be more potent than chemically synthesised pharmaceuticals. Today, 16% of all pharmaceuticals are biologic in nature – treating a wide range of disease areas.

What does Biopharmaceutical Manufacturing involve?

All biopharmaceuticals are manufactured in the same way. Closed, controlled reactors cultivate cells or organisms to produce large quantities of the medicinal product. During cultivation, the reactors are fed with nutrients and its temperature, pH, and aeration are controlled.

Once enough of the product has been produced, the reactor contents are harvested.

Further processing isolates, purifies, and stabilizes the bulk product. It is frozen and stored until formulation and dispensing into its final dosage form used by our patients.

To keep production free from unintended contamination by naturally occurring microbes, manufacture is mostly executed in closed, clean, and sterile equipment. Cleanroom facilities and personnel gowning (similar to hospital operating theatres) provide additional assurance of product quality.

GMP classifications in terms of allowable particle numbers and size per metre cubed. See paragraph below.

What impact does this have on MEP?

It is this final paragraph leads to a requirement for varying levels of cleanliness in rooms depending on their use. The specification for cleanliness is via a standard called Good Manufacturing Practice (GMP).

The rooms I am looking at require a GMP classification of either C or D. This is achieved by increasing the number of air changes per hour (ACH) to a minimum of 10 for class D rooms and 20 for class C rooms. Additionally specific bag filters are use in the Air Handling Units (AHUs) and HEPA filters inserted into the system (see Fran’s blog on ductwork testing).

What’s the problem / why have I got involved?

The strategy for meeting the ventilation requirements in the class D rooms is for high level supply and extract. Unfortunately there doesn’t appear to be enough ceiling space to achieve this; the reactors that cultivate cells are fed by pipework from above, in addition the ceiling is up to 5m high in places and the lighting is being supplied with LEDs, which leads to large emitter arrays being required. The knock on of this is that there is little space for both supply diffusers and extract grilles in the ceiling. We are therefore looking to provide high level supply and low level extract.

My task has been firstly to look at what diffuser options meet our requirement. I approached this in the following manner:

- Identify what the air velocity requirements are for the clean rooms – .15 m/s to .45 m/s for class D rooms. (CIBSE guide B)

- Use the ACH values and room volumes to work out what the required room air flow rates were. The assumption was made that the GMP requirement would be in excess of the heating / cooling requirement.

- Use manufacturer’s data sheets to narrow down the number of products that meet our requirement (figure 1 and 2). The main driver for this was the “throw”. Where throw is the distance from a diffuser to where the velocity of the air jet drops to 0.5 m/s. The throw that is achievable for a given diffuser will predominantly depend on its design, its use (heating, cooling or ventilation) and the flow rate of air through it. Most manufacturer’s don’t give a distance for “throw” in their data sheets, but do give a distance to the 0.2 m/s isovel (line of constant velocity), which is actually more use in my circumstance.

- A secondary consideration was ensuring that the noise rating of the diffuser was acceptable along with the pressure drop across the diffuser.

This has allowed me to scope a couple of potential solutions. I am now in the process of approaching suppliers to confirm the type of diffuser and suggested layouts. We’ll then be able to put this back into our model to see how it impacts other services and eventually write it into the specification.

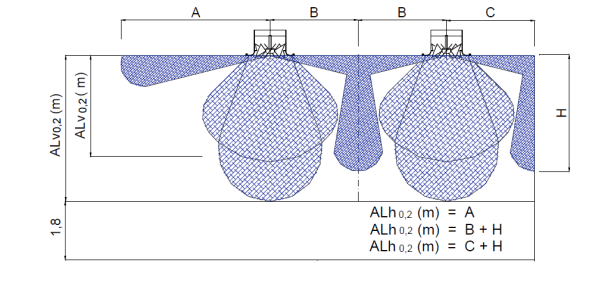

Figure 1. This figure is taken from a manufacturer’s guide and shows both the vertical and horizontal at a distance where the jet velocity has dropped to .2 m/s. The darker blue cloud indicates how the air jet would move when the diffuser is set up for isothermal or cooling conditions and the coanda effect is being utilised. The lighter colour bubbles indicate the blades in the diffuser being at a steeper angle to force warm air down into the occupied space. My room is 5m high and has 3m between diffusers, therefore ALv is 5m and ALh is 6.5m (the occupied zone is to the floor as the requirement is for cleanliness as opposed to the 1.8m indicated above for someone standing).

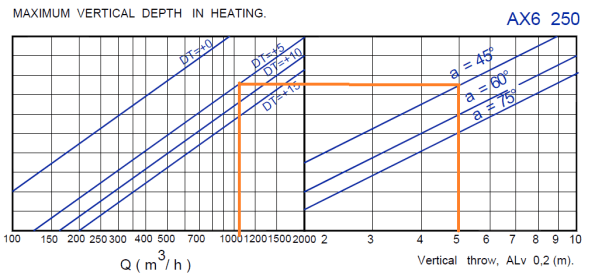

Figure 2. From figure 1 it is possible to calculate ALv and ALh. In my case ALv is 5m. I’ve used this with a blade angle of 45 degrees and a heating delta t of 5 degrees to calculate that one AX6 250 diffuser would need to be pushing through just over 1000 m cubed per hour to meet these conditions. This is then checked against the capability of the diffuser to see if it works, if it doesn’t either the blade angle can be changed or another diffuser has to be selected.

The next stage is to try and work out the low level return will work; part of the design brief is that GSK want the facility to conjure images of “ the Google of Pharmaceuticals” and for the process to be transparent. This is resulting in most of the internal walls being glass – not entirely sure how we’re going to turn glass walls into return plenum’s.

Departure from Battersea Power Station Phase One

On Friday I handed in my PPE, laptop and called time on my secondment with Carillion at Battersea Power Station Phase One. If I’m honest this brought about mixed emotions. If you’d asked me two months ago how I thought I’d feel, I’m confident the answer would have been, “elated.” At the time I was at a bit of a low point on the project and constantly frustrated with not being able to progress works in the manner I’d like. However, over the last couple of months things have improved and there’s been visible progress in the basement, which now means that I’m almost a bit sad to be leaving.

During my time at Battersea the building has moved from a structure that was only a few levels tall in most places, to one that is topped out bar two cores. In my opinion it now looks pretty dominating if you travel into Victoria on the train or walk west along the river from Waterloo. The structure moving up has allowed the basement to open up – back propping has been removed and water ingress issues have been mitigated (to an extent) which have removed many of the frictions of trying to work in the basement.

When I arrived on site MEP activity in the basement was revolved around the installation of pipework and containment. I thought I’d be involved in the installation of an energy centre and variations to external works; however, neither of these activities has started yet. As I left site I was working in 6 of 9 thermal plant rooms, 62 of 89 modules containing 300mm dia pipework had been installed, and 4 of 12 TX rooms were in progress. I’d hoped to see the filling and flushing of core A (programme date Aug, revised date Oct), but this was still someway off when I left.

I believe my attachment has been as success, having gathered experience in competencies A1, C1, C2, D1, D2, D3 and E2, E3. Awaiting confirmation from AER3 my focus for phase 3 will now be on A2, B1,B2,B3, and E4.

Is there anything I wish I’d done differently? Not hugely. I believe I’ve got the best out of what was available at Battersea. In an ideal world my attachment would have started and ended 3 months later which would have opened up more interesting MEP work. In addition I would have benefited from there being more Carillion mangers working in the basement area – part of the reason that things picked up in the last few months was that the structures team put an additional project manager in the basement to progress their works. Perhaps I should have seen this as an opportunity earlier on, but I didn’t see it within my remit and would have probably been getting out of my lane trying to manage the detail of ground workers, sheet pile and concrete subcontractors. I’ve also not touched on the tender process whilst at Battersea as the MEP side of the job has been beyond this. On reflection this could have been overcome by working on another Carillion job for a day week or a short period (something my boss suggested during my wash up interview). Although I’m not sure this would have worked in reality due to the pace of life at Battersea – probably why it was suggested during my final interview if I’m being cynical. Something for phase 1’s to bear in mind though as they head out on phase 2.

Would I do this job outside the Army? Probably not, although, I will bear in mind the fact that everyone has re-iterated to me, “Battersea is not like any job they’ve worked on before”. That being said the people have been great to work with, the atmosphere is similar to that in a Troop / Squadron and at the moment the money is good; I am not being replaced at Battersea, which is due to the fact Carillion’s prelims are tight and the people who’ve recently been interviewed to join the MEP team are asking for circa £85k plus package. Carillion will try and bridge the gap until someone else from the RSME arrives, however, I imagine at some point something will give and Carillion will decide to pay something close to the market rate to get someone else on board the team.

I’m now working at Bryden Wood Group for phase 3 within the Mechanical team. There are currently two projects I will be involved in. The first is a Biopharm in Ulverston (making Pharmaceuticals that are biological in nature), which will be the first of its kind for GlaxoSmithKline in the UK . This project is in the concept stage and valued somewhere between £100 to £150M. The second is steam plant at a London University which is only valued at £50K from a MEP design perspective, so hopefully lots of scope for me to get a lot of autonomy.

Installation of Raceway modules progressing well. The four pipes on the left hand side at high level are CHW and LTHW F&R. These came to site on modules like the one that can be seen on the ground. Then there is more LTHW & CHW pipework which was installed loose, gas and public health.

The view £15M will buy you. Looking out over London from the penthouse in core A. To the left of the picture is the main railway line into Victoria so a double bonus if the owner happens to be a train enthusiast.

Programme vs Quality

This blog follows on from my previous blog about getting ready for pre-commissioning flushing. This time I will be focusing on point 4 of the check list – having a complete system.

As previously mentioned the original construction programme date for starting commissioning was 17 Aug 15. I had managed to get my elements of the pre-requisites in place and it was now down to SRW to provide a complete system. SRW did not achieve this date therefore for once CCL were in the position to be able to write a notice of delay; something SRW have been all too keen to do up until know. However it is only really worth writing a delay letter if there is actually going to be an impact on the programme (something SRW seem to have missed the point on), otherwise you are writing a letter which has little impact contractually, wastes time and erodes good will.

By sitting down with my SRW counterpart it became apparent that the date of 17 Aug in the programme was plucked out of thin air / had a huge amount of float associated with it. The completion of flushing (six week process – 1 week fill, 3 week flush, 2 weeks for results to be processed) was linked to the start of commissioning which wasn’t required until 16 Nov according to the programme, however, the fit out matrix is at least 2 weeks behind in core A and therefore this date could be slipped to 30 Nov which gave us a requirement to start filling the system by no later than 19 Oct, which is the date we agreed on to start. Buying SRW 2 months more time, which seemed more than enough time to complete the works that were left to do.

Unfortunately this time has been squandered by SRW. 19 Oct came and went and although the system was complete in that it had been installed the requisite checks that I eluded to in my previous blog hadn’t been completed: visual inspections were not completed to identify and rectify snags. As of 20 Nov the system still has not been filled. It is now looking like this won’t happen prior to Christmas – if the system is filled now we’d potentially still be flushing during Christmas stand down. What is frustrating is that this is all down to an issues of balancing time vs quality. SRW simply aren’t on the same page as Carillion with respect to the quality we will demand. They have been pushing on trying to hit programme targets and in doing so are slipping on quality. Carillion will not allow SRW to proceed with filling and flushing until we are happy with the quality of the system and therefore SRW’s approach is inefficient in that they are going to have to pay to go back and conduct reworks.

Nobody from SRW appears to be managing the quality of the installation; they are letting their trade contractors call the shots and are taking their word at face value. This became very apparent in the lead up to 19 Oct. I had been monitoring progress on site and knew SRW were going to be nowhere near ready. My counterpart in SRW said this wasn’t the case. It was only when I sat him down, explained the issues and walked him out on site that the penny dropped with him as to what was happening. Everything I have picked up is blindingly obvious to see, but the SRW manager had been trying to manage from behind a desk. Unfortunately this doesn’t seem to have changed much and some of the key issues I have highlighted are still present. Although this is frustrating it is great for me in that I believe it presents some good C2 and C3 competencies to discuss at CPR.

The issues I have picked up include:

1.Union joints on pipework only being done up hand tight. What is particularly concerning about this incident is that SRW had recorded this section of pipework as being complete and having been air tested. Which then brings into question their whole process of checking the system.

2.Pipework not being installed as per the drawings. SRW’s response to this was that the drawings are only indicative! This would be fine if we had loads of space but the ceiling voids are tight and a small fortune has been spent on BIM for them. CCL sought assurances that this wouldn’t cause clashes with other services (it was obvious it would), SRW have not provided it and it is now becoming apparent that issues are developing, which will result in pipework having to be removed. An example of this can be seen below:

LTHW and CHW flow and return pipework above the ceiling grid of an apartment. The pipework had not been installed as per the drawings which means the lagging is now clashing with the flat duct work.

SRW’s solution to get around the clash between CHW pipework and the flat duct work is to use armaflex (black lagging above) instead of the normal Kingspan (silver), which isn’t acceptable. Why not? The employer’s requirements detail a specification for lagging on pipework which details the thermal conductivity of the material and thickness of insulation dependant on size of pipework. In this case the armaflex fails on both thermal conductivity and thickness. Although a 1 m length of sub standard lagging is unlikely to impact on the performance of the heat interface unit the main concern is that we are dealing with CHW pipework. Sub-standard insulation may lead to condensation forming on the lagging which will drip onto the ceiling and eventually result in a stain.

3. Clashes which prevent valves from operating which would prevent filling and flushing from taking place as per the RAMS.

My involvement in this element of the project has reinforced conclusions that I have previously drawn: the importance of getting out on site and looking at the progress of an installation on a regular basis, not just when it is offered up at an ITP hold point can not be under estimated. In addition far more information can be gleaned by talking to the bloke doing the installation than the manager of a main sub-contractor.

Pre-Commissioning Flushing

This blog will focus on preparing for pre-commissioning flushing of one of the LTHW and CHW systems at Battersea. As a means of introduction and for those that aren’t sure, flushing is the cleaning of pipework to ensure that it is free from debris, settled solids, suspended solids and certain bacteria. This is to ensure that sensitive equipment isn’t damaged (plate heat exchangers and terminal units) when incorporated into the system, that commissioning valves can operate correctly and that microbiologically induced corrosion doesn’t occur.

The contractors involved are:

Skanska Rasleigh Weatherfoil (SRW)- Main MEP contractor

Price Building Services (PBS) – Pipework trade contractor

PH Water & Air Technologies (PH) – Flushing trade contractor

Wyse Power (WP) – Temporary services

When looking at flushing a system there are four basic elements that need to be in place (I’ve annotated who is responsible for each element):

1. A water supply – Down to Carillion to supply

2. Electrical supply (for pumps to get up to required flushing velocities) – Carillion to supply

3. Drainage – Carillion and SRW to supply

4. A complete system – SRW to supply via PBS

I have been managing the preparation for flushing from Carillion’s point of view. This has meant ensuring that points 1 to 3 are in place to meet SRW’s requirements and also ensuring that the approach SRW will take complies with the employer’s requirements which essentially means complying with BSRIA’s BG 29/2012. In reality my main focus hasn’t been on the technical detail and has been on the simple task of trying to prevent SRW from flooding 6 floors of semi-fitted out apartments. The following is worth noting:

Water supply – The permanent Boosted Cold Water Supply (BCWS) on site was not yet installed, therefore a temporary supply was required. This was fairly simple to sort out. I gained confirmation from PH on what their requirements were (a 50mm supply) and then arranged for WP to install a spur from our site temporary supply (50mm) into the plant room where flushing would be taking place with a double check valve fitted to the end for PH to connect onto. If I’ m honest this was a bit of a gamble on my part. As I’ve come to learn this is just a game. Points 1 to 3 above were down to me to sort out. The target start date for flushing the system was 17 Aug 15 therefore in order to avoid a relevant event occurring (JCT term for something which causes delay) and delay notice being issued by SRW I has to ensure we had a water supply. The reason why this was a gamble is that although I was tapping into a 50mm site supply, this supply comes from 2no 5000l break tanks which back in Aug were supplied by a 25mm pipe. PH had a discharge license for 10000l a day and therefore there was a risk that PH’s activities could disrupt the water supply to site. Why did I take this gamble? I knew SRW would not have their system complete in August and I knew a larger water supply was coming to site in the near future. By putting my supply in I protected Carillion contractually – it’s much harder to prove a supply isn’t up to the job than it is to highlight that there isn’t a supply in place at all. What is more frustrating is that I needn’t have taken this gamble at all. I have subsequently read BSRIA’s BG 29/2012, which gives clear guidance on the size of supply required in Table 3.

An extract from Table 3 of BSRIA’s BG 29/2012:

less than 2000l system = 25 mm supply

2000 to 10000l system = 40mm supply

greater than 100000l system = 50mm supply

PH were simply asking for the largest supply they could possibly need, without looking in detail at the size of the system, in order to cover their bases. Assuming that our riser pipework remains at it’s largest diameter and the horizontal distribution pipework is the same as the largest size then the volume of the system comes out at 1959l – I only needed to provide a 25mm pipe which would have been met by our 25mm site supply leaving 10000l a day for site use (more than enough). An easy lesson learnt.

That’s just over 700 words, so I’ll leave it there for this blog and provide comment on my part in confirming SRW have completed the system (visual inspections, air test witnessing and NCRs) at a later date.

As an aside I’ve only got two weeks left on site. If anyone on phase 1 knows that they are coming to Battersea Power Station Phase 1 let me know and there may be scope to arrange a visit to site before I depart and switch focus to phase 3.

Sump Pump

This blog will focus on the installation of a sump pump in basement level 2 which I was involved with last week – another classic example of simple things taking time due to co-ordination (sump pump access is directly under the lay down point for a tower crane) and H&S constraints (confined space).

What was required?

The installation and connection of 3 no pumps into the sump pump chamber, drawing of power & data cables, installation of the control panel and connection of the control panel. Energisation and testing and commissioning of the system were outside the scope of the works at the moment as we’ve not bought beneficial use of the sump pump – yet.

How was I involved?

RAMS

A few weeks ago I was given the RAMS for the installation of the sump pump which had previously been reviewed by a Carillion MEP manager and returned as status C – works cannot commence. The plan was that I would just have to ensure the new RAMS has incorporated the comments on the old RAMS. Obviously this plan didn’t survive contact. The first box to tick on Carillion’s cover sheet when reviewing RAMS is, “have you reviewed phoenix for the appropriate documentation?” Phoenix is Carillion’s intranet which has policy and guidance documentation. Looking at the previous cover sheet returned by the other Carillion manager it was clear that this box hadn’t been ticked. So out of due diligence I completed a quick search for working in confined spaces, which for once returned a whole host of information (like the army intranet, Phoenix is particularly good at normally not allowing you to find what you want). The fallout from this was that the RAMS submitted by the subcontractor needed additional information adding and subsequently checking by other specifically qualified individuals. The subby wasn’t happy about the goal posts moving, but ultimately we got the safe system of work required in place. So what? The MEP manager that originally checked the RAMS has forgotten more about safe systems of work and MEP than I have learnt. The original RAMS were probably good enough, but if an incident had occurred without the correct procedures in place then Carillion would have been exposed. My involvement eliminated that exposure and it has reinforced to me the need to question and apply scrutiny.

EXECUTION

Getting works started

In order to get into the sump pump the trade contractor required the chamber to opened and vented, dry and free from sludge. I have now fully got into the mentality of site and understand that being overly proactive is wasted effort. Being proactive, but leaving something until it is fairly urgent seems to be the most efficient way to get works completed. Therefore the day before the works were due to commence I arranged for the sump pump to be opened and pumped dry. Prior to doing this I walked the area again and noticed that the lid had effectively been fixed in place by a small concrete spill which hadn’t been reported. This was rectified quickly enough and the area was then pumped dry. Looking inside the sump there appeared to be about 5mm of sludge left, which I didn’t think would represent an issue – wrong! The next day the trade contractor refused to enter due to the thin layer of sludge. Not on any health and safety grounds, but because their contract is to enter a clean sump. The options available were for the trade contractor to leave site (abortive works costs), see if we could instruct the sump pump trade contractor to clear out the small amount of sludge (unwilling to do so), which left only one viable COA – instruct our ground works contractor to enter the sump pump and clear the sludge. Fortunately this final COA was achieved by using pre-existing confined spaces RAMS, the groundworks contractor’s confined space trained personnel and the sump pump trade contractors equipment. A simple and effective plan which required detailed co-ordination to ensure all parties were aware of what was going on. The groundworks contractor was given all the certification associated with the equipment being used so the idea was that they owned the clearing out element of the works and all risks associated with that – making the delineation of responsibility and culpability clear if anything went wrong. In reality the sump pump trade contractor was still involved in monitoring confined spaces work (this wasn’t the plan) and so if something had gone wrong the water would have been muddied. As it was the area was cleared in about 20 mins of physical work after about 2 hours of getting everything geared up. The lesson I’ve re-learnt is that subbies are there to do a specific job and rarely step outside of their lane – don’t give them wriggle room. I should have had a plan in place to get the sump made spotlessly clean on the morning works were due to take place, any sooner and rain water would likely wash sludge back into the sump. What would have been even better is if the sump had been bunged when it was installed.

CO-ORDINATION

As mentioned in the opening paragraph the sump pump lies directly below a lay down point for one of the tower cranes. This issue was simply resolved by briefing into our daily 4Cs meeting that works would be being under taken in this area the following week for 2 days. As belt and braces I also had a conversation had with the Carillion construction manager for this area to fully de-conflict – no problems. What I didn’t do was speak to other MEP trades directly. The reason for this was that SRW have representatives at the 4Cs and as the contractor delivering the entire MEP package under “self delivery” it should be a safe assumption that different elements of the SRW package speak to each other. In fact it shouldn’t have required me to go to the 4Cs at all, SRW should be capable of doing this themselves. On day two of the installation this problem came home. SRW electrical package were trying to deliver stores whilst the installation of the sump pump was ongoing. As it was this was easily resolved by my involvement, but it is frustrating that I had to get involved. Carillion have bought “self delivery” from SRW and this should mean that the left hand talks to the right and they resolve these issues internally.

Pulling Cables

The final issue to resolve was the pulling of cables from the sump pump to the control panel location, a distance of 40m with a 90 degree bend. This is probably too far without an intermediate pulling pit. I was given a call to say the pulling cable was jammed prior to anything being connected. There are two pulling cables in this area, so I asked are you sure you are looking at the ends of the same cable? I was assured they were and that they’d reviewed the issued for construction drawings. A quick walk on site confirmed that they were trying to pull cord A whilst having undone the end of cord B. This was quickly resolved and also highlighted that the control panel had been installed in the wrong place. All simple stuff to resolve, but frustrating given that SRW are supposed to be managing the works and are far too quick to pass any problems up to CCL as quickly as possible. Luckily for me it allows for some additional CPR material so I don’t mind too much. Finally the length of cable pull and 90 degree bend proved too much for the thin diameter pulling cable that had been installed – the cables wouldn’t come through and there was a risk the line would snap. As expected SRW came running to CCL for thicker / stronger cordage in order to allow a winch to be used to pull the cables through. Having had to jump through hoops to get the works underway I took absolutely no delight in reminding SRW that they were the Design & Build MEP contractor, they had provided input into the design process with respect to the location of the duct and lack of a pulling pit and that as competent contractor with access to the for construction drawings they should have fore seen this problem. Strangely enough they got the problem sorted when it looked like they’d have to stump up for the abortive work costs.

Yippie kay yay

I was planning on blogging about flushing and COA analysis for drainage, however, something much more interesting has cropped up today (in my opinion), so I’m afraid you’ll have to wait until next week for the car chase.

As a side note, before I start my blog, I’ve not seen any phase 1 students commenting on blogs on here. I know I was guilty of not commenting whilst on phase 1. If there is anything in particular that you want to know about on site, please let me know and I’ll try and tailor future blogs cover those topics.

I was always under the impression that 09.50 and 21.50 were cow-boy time. Not on BPSP1, its cow-boy time 24/7.

A few months ago I blogged about getting a temporary substation (TSS3) brought onto site. It has finally come to the stage when we’re going to connect TSS3 to the rest of the HV distribution network. This is to be done in two stages, initially TSS3 will be connected to TSS2 to create an even bigger radial. At a later date TSS3 will be connected to our DNO switch room to provide a ring main. This blog will focus on the first phase which is being conducted today.

In preparing for these works I reviewed the RAMS that were submitted by Wyse Power (our temporary electrical sub-contractor). After a bit of back and forth they were signed off at status A. This is an extract of part of the methodology:

1) Operatives will attend site for site specific induction as per the site rules.

2) Operative will read, understand and sign off this method statement and sign the back sheet.

3) The senior site operative (WP SAP & HVMS SAP) will carry out a site survey and POWRA– what risks will interface with works coordinate with site management and carry out a pre works check with all other WysePower operatives.

4) SAP (James Sherlock) to sign on and accept AP duties.

5) SAP to write up switching log and have approved by second SAP (Kevin Poole).

TSS2 to TSS3

6) SAP to carry out isolation and apply earth to SF6 Ring to TSS2 Ring Switch, fit safety lock and caution sign. SAP to fit danger sign to adjacent live equipment and HVMS SAP to witness. See ref 1 on schematic.

7) SAP to carry out isolation and apply earth to SF6 Ring to TSS3 Ring Switch, fit safety lock and caution sign. SAP to fit danger sign to adjacent live equipment and HVMS SAP to witness. See ref 2 on schematic.

8) SAP to confirm dead to jointing team.

9) SAP to issue permit to work for the connection of TSS3 to TSS2 SAP HMVS will hold the keys to the locks.

All pretty straight forward stuff. I spoke to the SAP yesterday and warned him off that as part of my education I’d like to come down and see how the above process worked in reality. The key part here is that Wyse Power knew that I was going to visit them. HVMS are a cable jointing firm who are being subcontracted by Wyse Power to connect the HV cable into the ring main units.

So what happened when I got to site?

Point 1 above- Complete

Point 2 – no RAMS on site and James confirmed to me that he hadn’t seen the RAMS. ARGHHHH!!!!!!

Point 3 – Complete

Point 4 – Not done.

Point 5 – No switching log present. The second SAP mentioned above is a project manager who is off site and therefore cannot sign the paperwork unless it was completed in advance.

Point 6 , 7, 8- Works not at this stage yet, but it was being discussed that padlocks be left off whilst the HVMS SAP went to get his own.

Point 7 – SNo permit to work produced.

Essentially the works being carried out are very basic, both the switches involved are already switched off and earthed and because of that the guys involved have got complacent. I had to stop the works, bring the SAP (James) up to my office and physically give him a copy of the RAMS, we then sat down and read through the RAMS. He then went away and produced all the necessary paperwork. We managed to get round the issue of the second SAP (Kevin who wasn’t on site) countersigning the switching log by virtue of the fact one of the HVMS workers was an SAP and was able to countersign.

All in all very simple to sort out, but hugely frustrating that I had to get involved in the first place.

7 click central

Things aren’t looking so rosy in our principal M&E sub-contractors’ office. Their office consists of about 40 personnel and they’ve been on site since January, however, to date they’ve had 12 people leave the project (granted one was a death – natural causes) and a further 4 are ringing for a taxi. As I understand it this is incredibly high turn over and made even worse by the fact that SRW is a company that prides its self on normally having low turn over.

What’s the issue?

Its very simple – toxic leadership. SRW’s package is split into two halves – fit out (putting all the MEP kit in the apartments) and infrastructure (getting services from where they enter the building to the apartments). Each half is headed up by a director and both directors have a leadership style which leads a lot to be desired. This is resulting in the out flow of people. What is particularly worrying is that the flow doesn’t seem to be slowing down, if anything as the job is getting bigger and more pressure is being put on the flow is increasing.

What’s the impact?

The project is loosing some quality personnel, but even when an individual who isn’t particularly talented leaves there is still a loss of knowledge. The problem is further compounded by the state of the construction industry in London; between Battersea and Vauxhall alone there are over 5 major construction projects (that’s counting Battersea Power Station and it’s 3 current phases as 1). In short there are lots of jobs out there and a huge skill shortage to fill them. People who would have been section engineers are stepping up to fill package roles and package managers are becoming project managers. SRW are now struggling to recruit into the gaps they have in their organisation. A recent SRW vacancy at Battersea attracted 11 applications, but hasn’t resulted in anyone being placed. I’m not sure whether this is because there wasn’t anyone of a high enough calibre applying or whether the applicants got wind of the situation on site and decided to look elsewhere. SRW now have a significant number of gaps, which means that the work load of those that have stayed is increasing rapidly. This is causing problems in the way the works are being managed, increasing stress levels and will ultimately lead to more people leaving.

I’ve felt this first hand in the last week when I was engaging with SRWs commissioning manager about flushing a riser in order to bring on line temporary heating. It felt like the blind leading the blind – I’ve never commissioned anything in my life, but I felt like I had a better grasp of what was required than SRWs manager. Whether this is because he’s stretched in other areas or because he lacks experience I don’t know. Every question I put to him went straight to the trade contractor with no value added. I’ve also had to review the RAMS for this process this week, which was a painful experience. Again the paperwork has come from the trade contractor. SRW have signed it off as status A, which means it is absolutely faultless in their eyes. This is utter rubbish, it’s status C at best, which means it needs re-writing.

Every cloud has a silver lining

We were supposed to be starting flushing on Wed next week. I’m currently struggling to get drainage sorted for this activity, which means I was staring straight down the barrel of a delay notice. Fortunately for me SRW have only just (yesterday) submitted their RAMS. So I can contractually take 10 days to review the paperwork before telling them its crap and getting them to resubmit; SRWs half hearted effort checking their trade contractors paper work has saved my bacon (presuming I get the drainage sorted).

Once I’ve got TMR 2 out of the way I’ll hopefully provide an update on where we are with the flushing – I’m sure you can’t wait!

A small commercial conundrum

In my quest to get works in thermal plant rooms underway I’m still chasing down builderswork interconnections that have been missed. In order to get the works underway a simple instruction is requied, which is easy to get from the blockwork-package QS. It’s him that who makes the decision as to who will cover the costs for the remedial work, but I had to provide the background information as to what has happened. In this instance the requirement was for 3 no holes to be formed in a blockwork wall which were missed at the time of construction due to the blockwork contractor (Swift) not having the information at the time of construction. The issue is complicated slightly by the fact that the BWIC details have subsequently been revised. The timeline of events is as follows:

03 March 15 – SRW issues BWIC information to CCL, drawing revision is C01.

02 June 15 – Swift start constructing blockwork in thermal plant room 12.

05 June 15 – CCL issue CO1 revision BWIC information to Swift (our informaiotn management isn’t exactly great, but that could be a completely seperate blog).

09 June 15 –Swift complete blockwork in this area, BWIC formed on one wall, but 3 missing on another wall.

02 Jul 15 – SRW issue CO2 version of BWIC information to CCL. Hole location does not change, but size does (increases).

05 Jul 15 –CCL issue CO2 BWIC information to Swift

I ran this by an MEP QS prior to submitting it who was unable to shed any light on who would pay. I’ve had the instruction issued and the work has been carried out, but I’ve not had the opportunity yet to discuss the matter with the blockwork QS for my education. In my mind the CO2 revision would have caused Swift to have to carry out the work anyway and the differenct between knocking out 2 blocks and blocks is minimal so SRW should bear the cost (which will be trivial). Thoughts?

All this paperwork is great, but who’s building the job…

This blog will focus on my exposure to the quality management system at Battersea Power Station Phase One.

To set the context of this blog I will provide a bit of an update on the project. It’s fair to say that the pace of life at Battersea power station is getting frenetic. Carillion (CCL) and Skanska Rashleigh Weatherfoil (SRW) finally got agreement on the MEP programme we’re working to, so pressure is naturally being applied to hit deadlines. This pressure is added to by the fact that CCL procured the job during the recession, under resourced it and have no immediate plans to increase the level of resources available. As I have previously mentioned the site has significant logistic constraints and complexity due to the sheer scale and profile of the job. Given these factors I would have thought it prudent to keep processes simple and not re-invent the wheel. This is certainly not the case with regards to our quality management system.

Battersea’s quality management system.

It will come as no surprise that the main way in which CCL are managing quality during the installation is through the use of Risk Assessment and Method Statements (RAMS) to ensure the planned method of installation is correct and safe. This is then followed by Benchmarks (part of the JCT contract) which must be the first of type on site to set the standard for the works including how it was achieved not just the finished product, Inspection and Test Plans (ITPs) and check sheets to ensure that the installation is being carried out as per the agreed specification, this information is then recorded in a package plan file which is the audit trail to the client that CCL have done their job. The processes I have just outlined seem straight forward and make sense to me. Where I believe Battersea is starting to over complicate things is through the overly zealous use of Benchmarks.

Benchmarks

Under the JCT contract that CCL have signed up to there are approximately 250 benchmarks that are required, none of which are MEP related. There are further 140 non-contractual benchmarks that have been created internally by CCL, the majority of which are attributed to the MEP team. Each benchmarks requires SRW to pull together an 8 page document with additional supporting evidence (details of the specification that the benchmark relates to, photos of the installation, relevant extracts from the RAMS and drawings). This paperwork then needs to be red penned by CCL, signed off by 5 people and utilised to inspect the benchmark itself on two separate occasions; quite a time consuming process in total for what is effectively a discretionary task. Due to the lack of resources on site these non-contractual benchmarks are not being closed out in a timely manner. As mentioned above the benchmarks are supposed to be the first of type on site. However, in reality by the time the paperwork is completed and the benchmark signed off the job has progressed far beyond the first of type being utilised as a benchmark. As an example, a recent benchmark for electrical containment took so long to close out that approximately 50% of the total installation had already been completed. In theory the works should have been stopped until the benchmark was signed off. But on a job that is already behind schedule that wasn’t going to happen. With regards to the specific example of the electrical containment, one of the reasons work wasn’t stopped was that everyone knew (from walking past it on a regular basis) that the work was being installed to a high standard. Therefore what was the point of this benchmark other than to tick a box on an excel spreadsheet? I believe the production of the associated paperwork took up valuable time that could have been better spent managing other areas of the job which would have resulted in improved quality. I have highlighted my concerns and they are shared by other members of the CCL team, however, we are being told to soldier on.