Archive

My biggest fan – 15min read

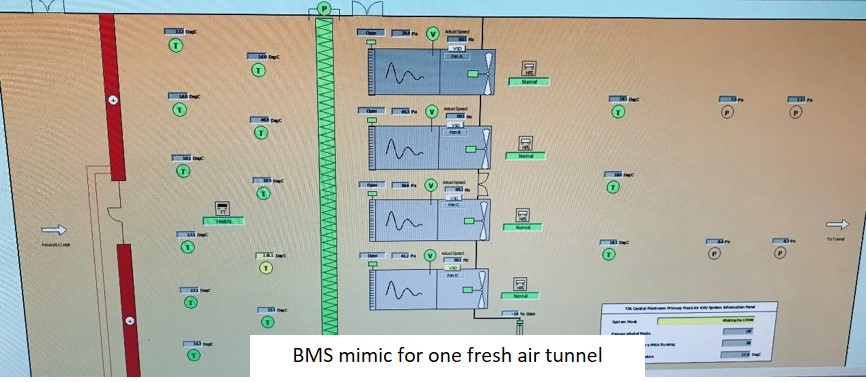

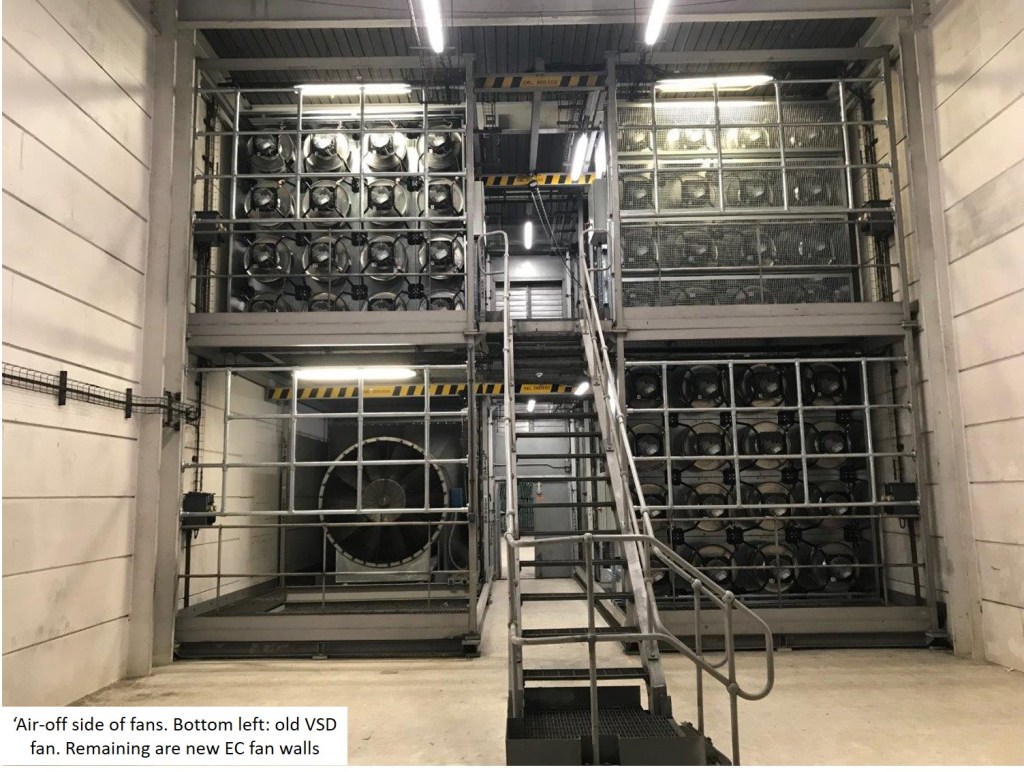

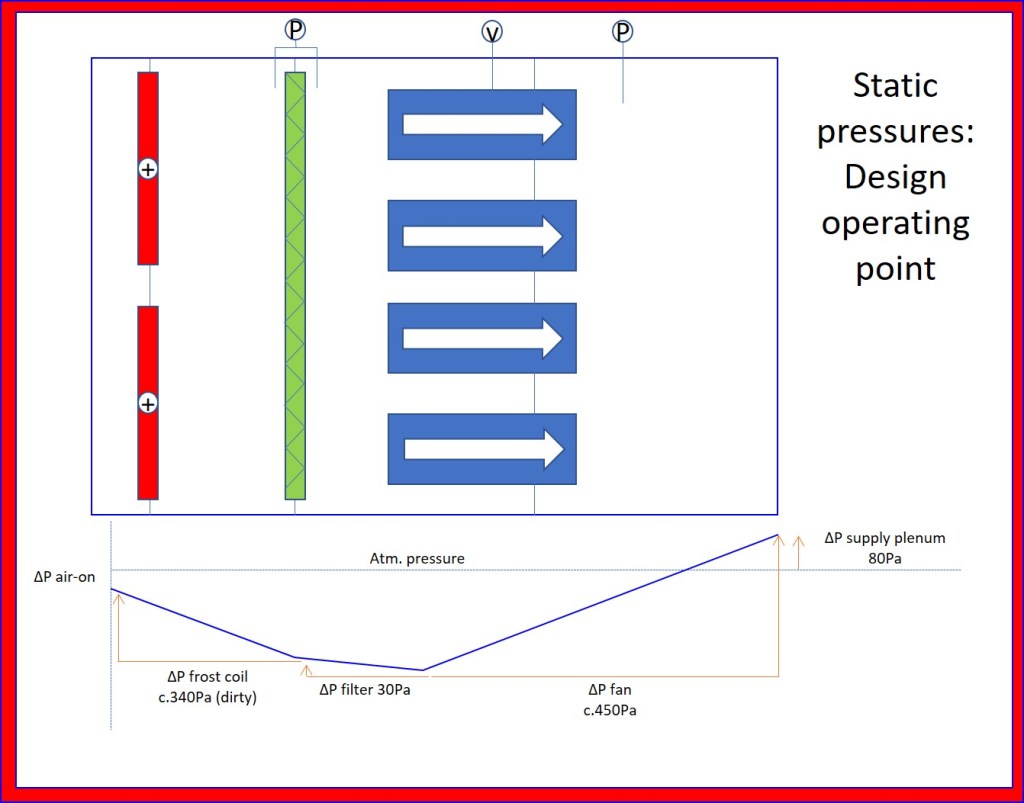

Part of the portfolio I have responsibility over as PM is the replacement of variable speed drive (VSD) motors with the retrofitting of electronically commutated (EC) fan-motor units (energy efficient motors, DC brushless motors by another name, sorry for the simplification John Marsh!). One of the sub projects is the removal of the original VSD fans from the three primary fresh air tunnels which provide fresh air to Terminal 5A. Essentially, there are three tunnels each with design flow rates of between 180 and 240 m3/s and a downstream plenum pressure set point of 80 Pa. These design conditions allow the AHUs within the terminal building to be able to ‘suck’ (I know pumps only ever push, Mark Hill!) fresh air into occupied spaces within the building. Each of the old VSD fans was replaced with a fan-wall composed of multiple EC fans.

The project was completed in late 2019 and the static pressure in the plenum has never consistently reached the 80 Pa set point. There has been multiple inspections and heated conversations over who is to blame.

On the client side, Heathrow are clearly disgruntled at the increased energy demand of the fans, currently running at 100% (with no redundancy) and not meeting operating conditions. The operational engineering team within the terminal believe it to be a lack of capacity from the newly installed EC fans.

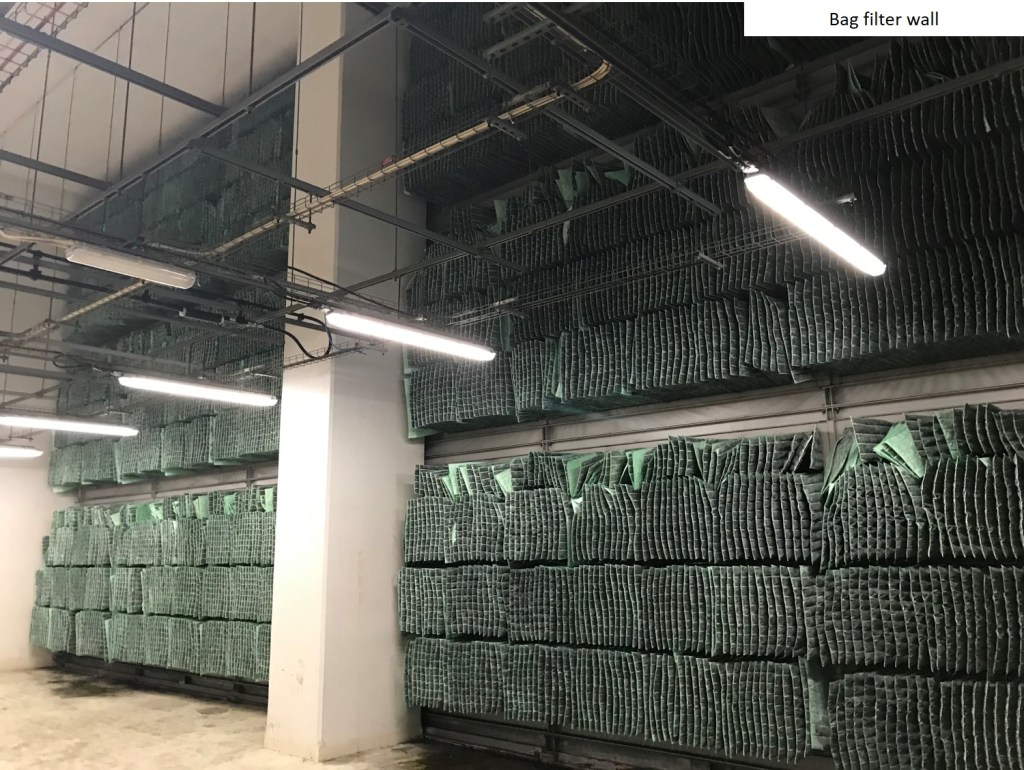

On the contractor side, they believe the fans are being ‘choked’ through poor cleaning and maintenance of the frost coil and bag filters that are the in the system and that the design is as specified by the original project scope.

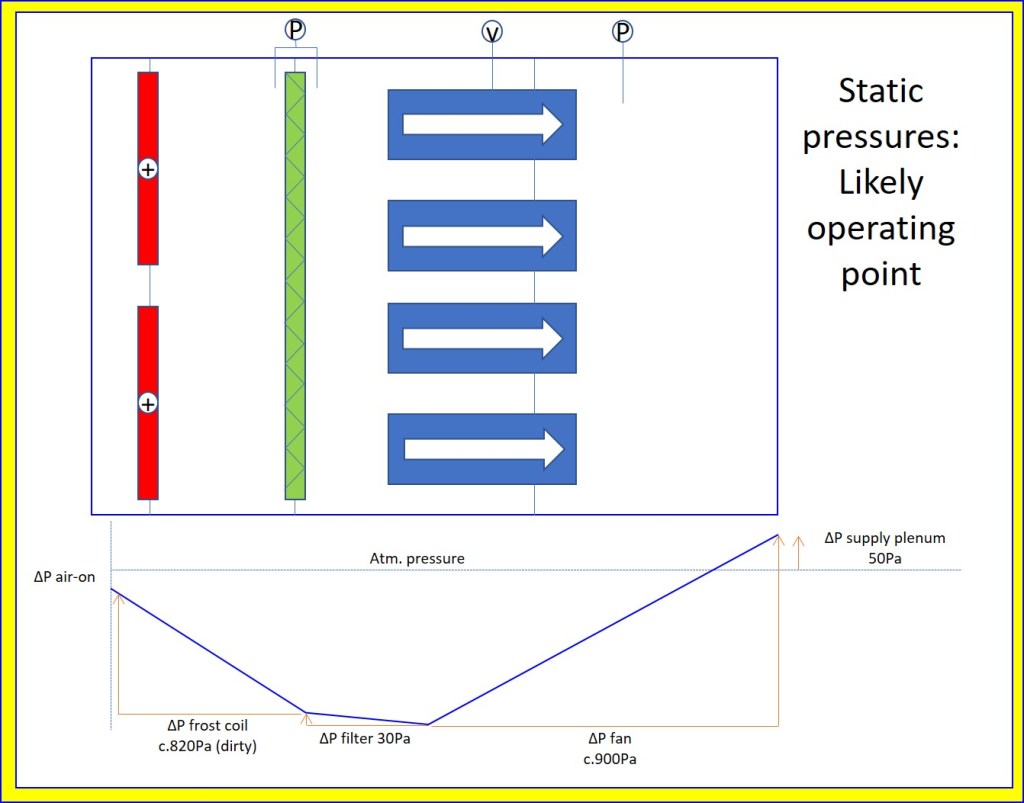

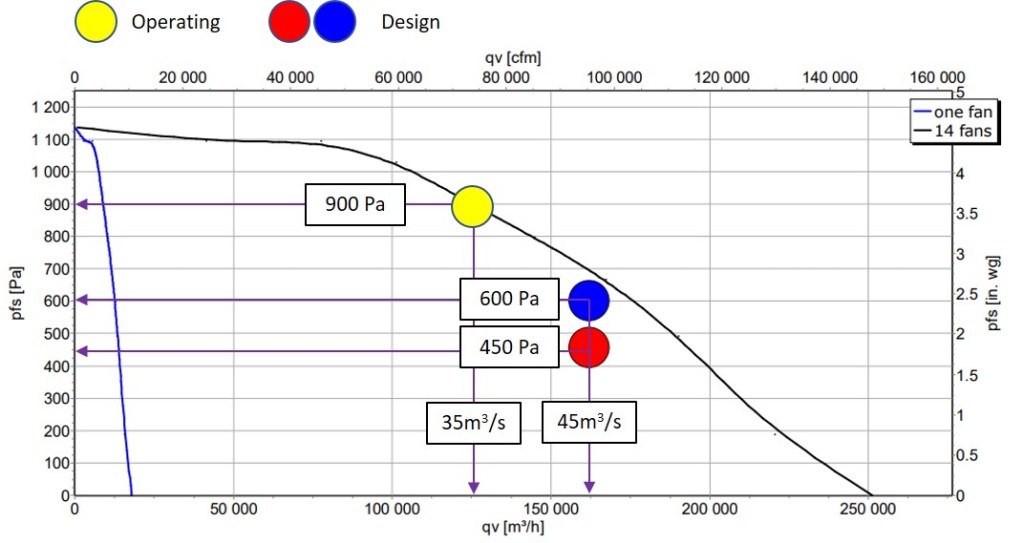

There had been a plan to install more pressure and temperature sensors within the tunnel but at this time there is no way to measure differential pressure across the frost coil or fans. The manufacturer of the EC fans published the fan-curve data as in the figure with the two operating points based on the original project scope that was handed to them in early 2019. Original commissioning information puts the maximum allowable differential pressure across the frost coil as 50 Pa and the bag filters at 225Pa. The frost coils are currently extremely dirty and gummed with incoming material entrained in fresh air. Although DP across the frost coils cannot be directly determined the bag filters are not running at anywhere near this upper limit.

The figures below show the likely operating conditions as is, along with the two cases published by the manufacturer, IF the EC fans are performing as per the published fan-curve.

Research into original commissioning information has revealed that there is a large difference between the maximum available duty of the VSD fans removed and the smaller EC fans retrofitted. Although this extra duty is not required in ‘normal’ operating conditions (ie. if the filters and coils remain clean and with low enough DP) in the past it could have easily allowed to overcome poor cleaning and maintenance of components by simply ‘turning it up to 11’.

Following some investigation I think there to be are a number of possible outcomes, in order of likelihood, following the correct cleaning of the frost coils an replacement of bag filters:

- The system will operate correctly and pressure set point is reached. Everybody goes home happy and electricity bills reduce.

- There still lacks the sufficient pressure in the fresh air plenum. This will then cast doubt upon the EC fan capacity and likely reveal that the original scope handed to the manufacturer did not allow for the total air flow capacity of the original VSD fans; no fault of the designer. Due to the size of the project this will likely be tolerated and downstream operation strategy of AHUs will have to change from working on pressure set points to perhaps CO2 levels.

- The EC fans are found to be lacking still and only through extra monitoring of running conditions of the fans (differential pressures and air volumes) the manufacturer is held to account.

The show must go on

Despite what we may have been reading in the newspapers regards various lockdowns across the Schengen zone and wider European continent, the airline industry has been limping on and where possible, facilitating both freight and passenger movements in and out of the UK mainland. The infographic below shows the total relative numbers of passengers moving through Heathrow. For sensitivity reasons absolute numbers have been removed however it still gives an idea of the relative reactions to local lockdowns. For reference, note the significant dates below in the table whilst watching the relative movement of each country. (Click replay at the bottom of infographic to do so).

| Date | 14 day quarantine lifted | 14 day quarantine imposed |

| 10 Jul | ESP, FRA, GRC, DEU | |

| 25 Jul | ESP | |

| 8 Aug | BEL | |

| 20 Aug | HRV, AUT, FRA, NLD | |

| 22 Aug | PRT | |

| 29 Aug | SWI, CZE |

Too simple a process to get wrong, right?

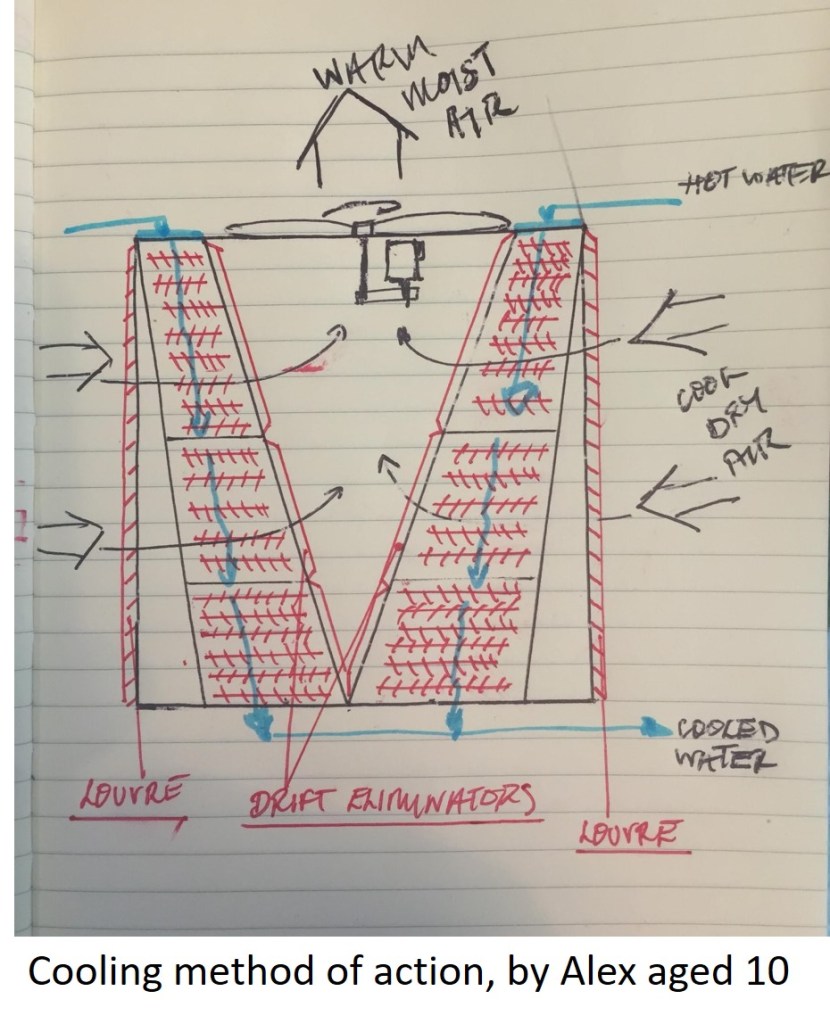

Terminal 5 at Heathrow is served locally by a set of open-loop cooling towers that are on the roof of the Terminal 5 Energy Centre, where heat can be dumped following coolth being provided to the terminal building. The operation of open loop cooling towers is wonderfully simple. The method employs latent cooling by passing the hot water, as a product of the cooling process, through a distributor (think sprinkler set) over ‘fill’ material (think plastic lattice material) that is designed to cause disruption to the flow path and encourage droplet formation. Concurrently, a cross-flow of air is forced through the fill by the presence of a whacking great fan mounted on the top.

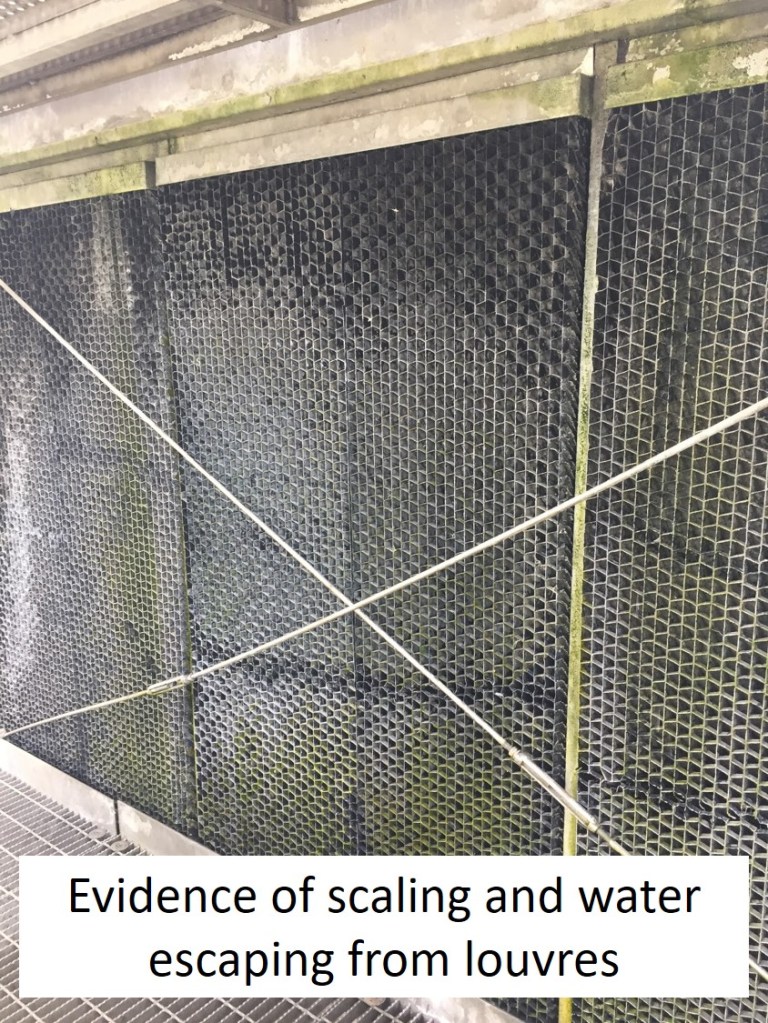

Amongst the many design controls that exist are intake louvres (on the visible outside face of the tower) and drift eliminators (on the internal face of the fill material). The job of both of these is largely to prevent as far as possible the escape of water droplets from the fill material both into the leaving air stream and also the surrounding area. Escaping water causes problems including; legionella risk, increase make-up water needed (some is always lost in the leaving air stream) and increased scaling of all components.

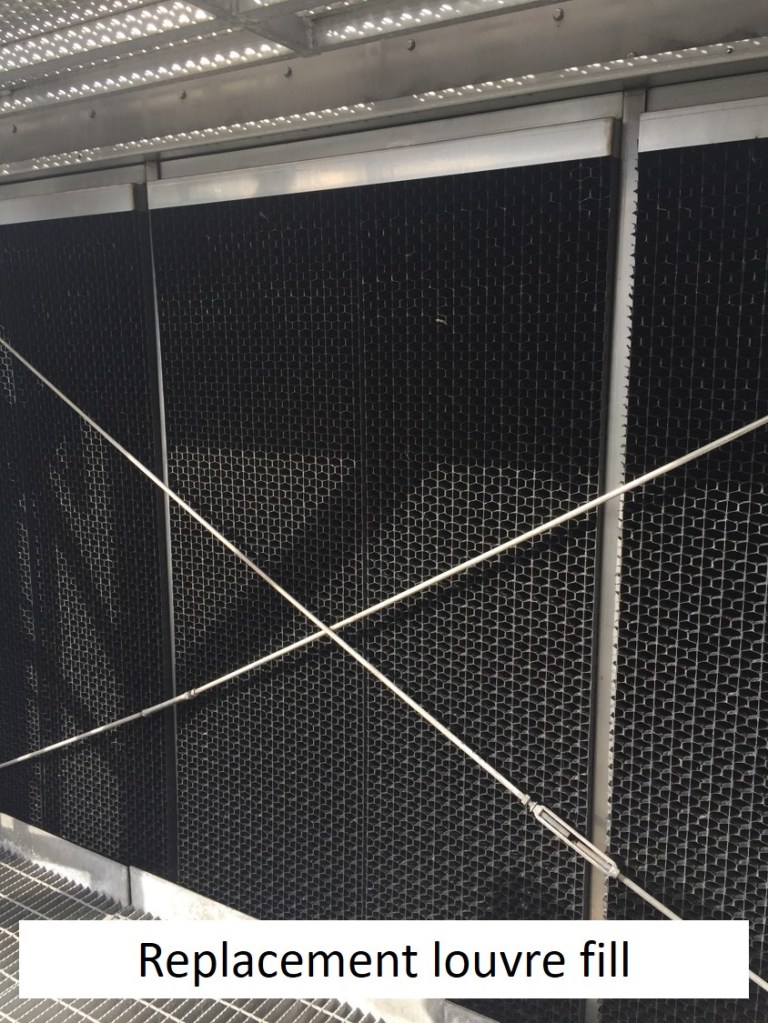

Inspections last year of the T5 cooling towers by the HSE revealed all of the above issues and an improvement notice was issued. Long story short, the louvres and drift eliminators had been installed upside down (think a cheese grater the incorrect way up) so were effectively continually funnelling water out of the cooling tower at a fairly alarming rate (discovered once accurate measuring of the make-up water had been carried out). For a simple installation error that occurred in the past the renovation process now involves the replacement of fill material (albeit due to a separate issue of incorrect de-scaling regime), replacement louvres and eliminators and in some cases replacement of belts, pulleys and fan drive-shafts (where the budget can accommodate) as a result of scaling and corrosion. Not bad for mis-reading the ‘This side up‘ label.

Heathrow back on telly tonight – ITV 19 Aug 8pm

Tonight sees the 12-part series begin again which follows Heathrow as ‘Britain’s busiest airport’ (at time of filming during Winter months 2019!). The soothing tones of the national treasure Joanna Lumley provide narration. If my attachment lasts long enough I hope to appear in the coming 2020 series at the new-guy-on-site.

Use of UV light in air disinfection (12min read)

BLUF: Recent industry guidance has suggested that increased fresh air proportion is one of the best ways to de-risk person-to-person transmission of COVID pathogen. This approach brings with it significantly increased energy costs in fresh air heating (winter) and cooling (summer). There are a number of companies that have been offering Ultraviolet Germicidal Irradiation (UVGI) as a potential solution to disinfect the recirculated air of any pathogen so that plant duty is reduced to pre-COVID levels. The technology is not new but comes with uncertainties and health warnings of ozone production.

The use of UV light to render pathogens (virus, bacteria, fungi etc.) has been around for a fair while and was predominantly used to disinfect bulk water. Similarly, the study of virus susceptibility in when airborne is not a new topic. Link here to a 1936 study on just that.

There are many commercial products available today that use UVGI but they largely fall into three main categories; duct-mounted, upper-room and individual unitary systems.

- Designed to disinfect EITHER static elements such as coils/plenums/condensate pans or a moving air stream. The two applications require largely different power UV bulbs given the different exposure times.

- CAPEX for installation can be large and building service set-up may not always lend itself to the components.

- Designed to disinfect the upper proportion of air within a room that is served by traditional mixed-ventilation. It is unsuitable for typically larger spaces that employ displacement ventilation, unless CFD is employed to confirm air-flow patterns.

- There is an inherent risk of exposure to UV light during the typical 24-hour operation and the use of occupied space must be considered. Dangers and safe use practice have been covered in the past; example papers here and here.

- These ‘plug and play’ solutions typically serve smaller areas (up to 30m2) and have a flow rate of around 20 litres/s. The ease of installation makes them favourable in places that may not be directly served by fresh air but only have an extract, such as bathrooms whish can be designed to be in negative air pressure.

Risk

In all of these solutions UV light is the main mechanism of rendering the pathogen unable to replicate. Many of the manufacturers also actively publicise that the production of ozone (O3) is beneficial in rendering pathogens and odours neutral. Whilst the mechanism is not disputed, the use of ozone to disinfect water and air has been longstanding, there is no universally accepted limit of human exposure to ozone within the built environment. ASHRAE have stated that safe ozone levels ‘would be lower than 10 ppb and that introduction of ozone to indoor spaces should be reduced to as low as reasonably achievable’.

All of the above solutions will go some way to preventing large-scale person-to-person transmission or the movement of virus-laden air from one space to another. There still exists the risk of person-to-person transmission from coughing/sneezing/breathing in close proximity so the array of distancing/cleaning measures could not be abandoned in favour of a ‘silver bullet’ approach.

Has anybody else been approached by contractors promising a wholesale return to work if only a magic HVAC solution is employed?

Air do we go from here?

In the coming weeks it looks like we will begin the return to normality and to start occupying the spaces that have been the reserved for the essential workforce. As the built environment begins to take higher occupancy levels there is a need to deal with the risk of a person-to-person transmission of Coronavirus.

It is generally accepted that when a person coughs/sneezes/talks the Coronavirus pathogen is spread in one of two ways. The expelled droplets either behave ballistically and land on another person/surrounding surface or the droplets are aerosolised and are subject to air-buoyancy effects. The later of these mechanisms is where HVAC systems play a key role in controlling infection.

Given the novelty of the Coronavirus there still exists considerable conversation over how best to manage the ventilation systems of occupied spaces in order to reduce this risk. I have collated below the information from key groups (CIBSE, PHE, REHVA and ASHRAE). As you can see there exists conflict around topics such as RH and ventilation rates. I would be interested to know if there are any other individuals who are dealing with the same risk and having to implement a new or revised HVAC/building utilities strategy.

| CIBSE: CoVID-19 Ventilation Guidance (Summary) v1 9 May 20 Well ventilated rooms dilute pathogens and poorly ventilated areas carry a higher risk of airborne transmission Fine aerosols (from coughing and sneezing) remain airborne for several hours Duct cleaning has little or no effect on the prevention of spread of pathogens Specific guidance: Open doors and windows as much as possible to increase natural ventilation. Keep WC windows open as much as possible Maintenance staff to wear adequate protection when changing filters on A/C units Avoid recirculation where practicable Heat recovery devices in AHUs to be turned off |

| Public Health England: Infection prevention and control guidance – 27 Apr 20 “In light of limited data for SARS-CoV-2, evidence was assessed from studies conducted with previous human coronaviruses including MERS-CoV and SARS-CoV. Human coronaviruses can survive for up to 5 days at temperatures of 22 to 25°C and RH of 40 to 50%. The rate of clearance of aerosols in an enclosed space is dependent on the extent of any mechanical or natural ventilation – the greater the number of air changes per hour (ventilation rate), the sooner any aerosol will be cleared. The time required for clearance of aerosols, and thus the time after which the room can be entered without a filtering face piece (class 3) (FFP3) respirator, can be determined by the number of air changes per hour (ACH) as outlined in WHO guidance.” Specific guidance: “…A single air change is estimated to remove 63% of airborne contaminants, after 5 air changes less than 1% of airborne contamination is thought to remain. A minimum of 20 minutes (recommend 2 air changes) in hospital settings where the majority of these procedures occur is considered pragmatic” |

| REHVA: CoVID-19 Guidance document (Summary) – 3 Apr 20 Large and small particles (aerosols) are ejected from an infectious person. It’s the latter which are of concern for HVAC systems. Well ventilated rooms dilute pathogens. Poorly ventilated areas carry a higher risk of airborne transmission Heat recovery devices in AHUs usually work poorly and leak. Areas which have comfort cooling or heating need intervention. RH has little or no effect virus susceptibility. Specific guidance: At nights and weekends, do not switch ventilation off, but keep systems running at lower speed Ensure regular airing with windows (even in mechanically ventilated buildings) Avoid open windows in toilets to ensure the right direction of ventilation. Mechanical ventilation to run 24/7. Instruct building occupants to flush toilets with closed lid Switch air handling units with recirculation to 100% outdoor air or 400 ppm max of CO2 Do not plan duct cleaning for this period Regular filter replacement and maintenance works must be performed with PPE including respiratory protection Maintain social distancing measures to guard against person-to-person transmission |

| ASHRAE: Position document on infectious aerosols (Summary) – 14 Apr 20 “…Even the most robust HVAC system cannot control all airflows and completely prevent dissemination of an infectious aerosol or disease transmission by droplets or aerosols. Ventilation with effective airflow patterns is a primary infectious disease control strategy through dilution of room air around a source and removal of infectious agents. However, it remains unclear by how much infectious particle loads must be reduced to achieve a measurable reduction in disease transmissions.” Specific guidance: Air distribution patterns have an effect on distribution of aerosols Differential room pressurization can influence air flows Higher efficiency filtration (MERV-13) reduces concentrations of aerosols Increase outdoor ventilation as close to 100% as possible, 24/7 UV light with 265nm wavelength provides a good germicidal effect RH of between 40 and 60 RH is optimal for reducing microorganism survival Bypass energy recovery systems |

| World Health Organisation – Getting your workplace ready for CoVID-19 (Summary) – 3 Mar 20 No specific guidance on HVAC systems or strategies is provided in relation to COVID-19. |