Archive

Modification of post tensioned concrete

A quick reminder… I know all C’s have this covered but for the E&Ms, unlike conventionally reinforced and mass concrete, the modification of pre-stressed concrete is complicated due to the potential energy stored in the member. If suspended, all members contain gravitational potential energy but prestressed concrete stores elastic potential energy in its stressed tendons. This makes the modification, demolition and decommission of prestressed concrete members a more complex operation. Moreover, an alteration to any part of a pre-stressed member is highly likely to effect the entire structure.

With this in mind, you can imagine my horror as I was recently told I was responsible for the modification of a post tensioned slab which formed part of an exisiting structure adjacent to my project.

Sitch… In brief, I have got to co-ordinate the removal of a strip of PT slab (2m x 17m x 250mm thick), which cantilevers from ground level, over our basement, obstructing progress. Our structure will tie into the existing slab once we reach ground level. The image below shows the offender, north is up.

The western most 12m of the slab is 5m above our current rock level, the remainder is 10m above a lower rock level.

Thoughts so far… Having consulted almost everyone in the office, the structural engineer consultant and the PT sub-contractor I have come up with the following methodology…

Confirm effect of these works on remaining structure, temporarily back-prop remaining structure if required, back-prop the slab with falsework, provide edge protection, confirm tendon locations, expose tendons and confirm grouting, anchor the tendons with new ‘onions’ if required, cut strands, cut slab into manageable sections, sling and crane out, treat exposed edge of remaining slab with epoxy paint to prevent corrosion. Once the new structure ties in to the existing, any temporary back-propping will be removed.

I’ll take some photos and let you know how we get on.

More heritage complications…

Consistent with my other blogs, this one also focuses on a heritage issue. Our structural design consultants have deemed the heritage building so unstable that much of it needs remediation before adjacent works can continue. Whilst there are many areas which require attention, this blog will focus on ‘The Southern Wall’. An elevation of the Southern Wall is shown in Figure 1. It is the wall without windows, half painted grey and it is a miracle the thing is still standing.

Figure 1.

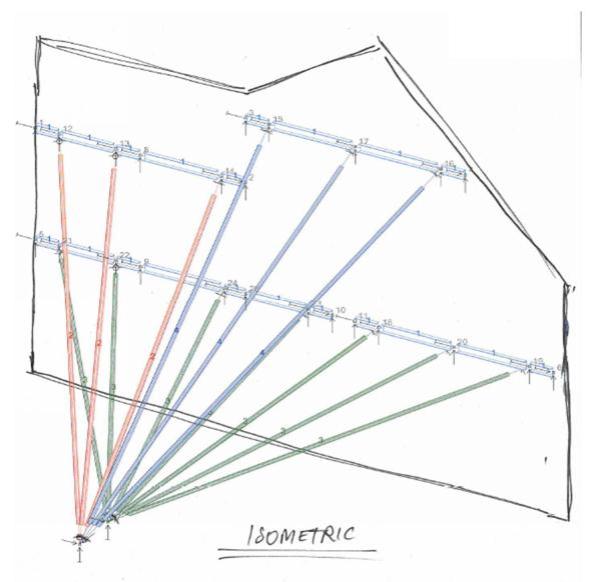

Several methods of reinstating the structural integrity of the building have been investigated but due to the time it takes to gain permission to do almost anything inside a heritage building, the level of internal instability between floors, contractual complexities and more – a temporary external fix has been selected. The solution involves three levels of walers being attached to the wall and then braced by a series of props. The solution is illustrated in Figure 2 and Figure 3.

Figure 2.

Figure 3.

This solution minimises the impact on the programme and allows works in the vicinity to continue, largely uninterrupted. The lower most waler is supported by the green props which all converge on to a single brace plate (BP1). The brace plat is bolted to the existing capping beam, but has had to be drilled to slot over the starter bars. The other two walers are braced by two separate groups of props, all of which converge to a second, separate brace plate (BP2). See Figure 4 for detail. Connection details are illustrated in Figure 5.

Figure 4.

Figure 5.

Not only does the steel provide support in elevation, they also prevent the road side elevation from falling into the adjacent street. It is difficult, but possible to see in Figure 1 that the western most 1.8m of the building (the left hand side) is almost entirely separate from the rest of the structure. Existing internal braces go some way to remediate this problem, but the proposed solution will help to prevent the matter from getting worse.

The long term solution is expected to be in the form of timber frames which will be sandwiched between the ceilings and floors of the building. Due to the issues highlighted at the start of this blog, this long term solution will be tackled in the distant future. This temporary solution is due to be constructed this week, I will post photos once complete.

What’s that Skippy? Someone’s trapped down a well?

Well, well, well… I have often found myself taking one step forward and two back as a direct result of working alongside a heritage building. Several issues have arisen but this blog will focus on one – a 19th Century water well.

Given that we are working on an old brewery site, some distance from the nearest river, the existence of wells is to be expected. What is most frustrating with this recent issue however is its location, see Figure 1.

Figure 1.

Figure 2 is an image of the well, after being ‘carefully discovered’ by an excavator. The well is approx 1.4m in diameter, the A3 clip board in the image gives an indication of the scale.

Figure 2.

Unfortunately, not only did the well caused me to cease works whilst the Archeologists investigate its historical importance, but it is located exactly where a tie back beam is designed to sit and almost exactly where a pile was designed to sit.

Fortunately the well issue has now been resolved. The Archeologists have conducted their assessment and have allowed us to continue and the clash with the beam and pile has been avoided. The well can be excavated to a reduced level sufficient enough to allow the tie back beam to bridge across it. The pile was required as part of a temporary piling bridge allowing us to use a 30t piling rig alongside the shoring wall. As a result of a separate issue, we have redesigned the foundation piles in this area, allowing a 20t rig to be used. The surcharge load resulting from the 20t rig can be resisted by the shoring wall without the assistance of a temporary piling bridge. The bridge and its piles are therefore no longer required – catastrophe avoided.

Temporary v Permanent…

Situation… So I am responsible for the section of the structure which will envelop the heritage building in the image above. In the permanent state, the structure will surround the heritage site as shown in the two images below…

Issue… Whilst the beam, which allows level 3 of the structure to cantilever over the heritage building, clears the roof in the permanent state, it fouls it in the temporary. The beam has to be poured in two stages due to its depth. In order to achieve the required strength between pours, the depth has to increase from that required in the permanent state. This causes the beam to foul the roof of the heritage building… Ah!

Options…

- Accept the collateral damage and remove a section of the parapet wall to allow for the beam.

- Prop the beam in the temporary state, allowing the beam depth to be reduced to that required in the permanent condition, thus avoiding a clash with the roof. However, to accommodate these props the floor boards and roof tiles will need to be removed and ceilings penetrated. The props will have to be strategically positioned to avoid joists and rafters. Once the beam has reached its required strength, the props can be removed, floor boards and tiles replaced and ceilings patched.

The heritage authority aren’t exactly happy with either of these options but think option 1 is the lesser of the evils. A structural survey of the heritage building is soon to take place and if I were a betting man, I anticipate huge aspects of the heritage building will be condemned. If the floors, ceilings and roof need replacing, option 2 may take the lead.

I will keep you abreast of the situation once a decision is made.

I’m sure Greg told us not to start without a contract?

With an 80,000m3 hole in the ground, the Client has shown significant commitment to the ‘DUO – Central Park’ project, albeit with a different contractor! Brookfield Multiplex are now lined up to continue the project, but are yet to secure a contract. Although a contract is yet to be agreed, a site office has been established and considerable effort has been spent, along with $1 million, in preparing for the project. Before my arrival the anticipated start date slipped two months. Since my arrival it has slipped again, an unrelated matter I’m sure. Multiplex now expect to establish site in April and commence works on 2nd May. Confident that a contract will be reached, we are using this time to prepare for the task, refining the design on a daily basis. With such a rare opportunity to conduct such in depth preparations – nothing should go wrong once the work starts… right?