Archive

No room at the inn

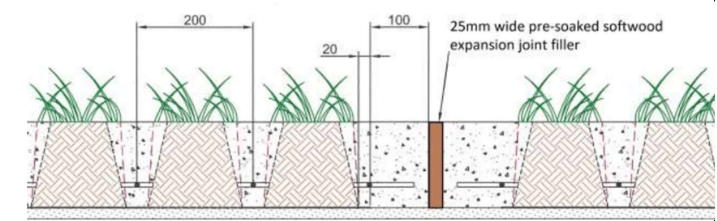

An interesting, potential Pandora’s box, request has been posed to me by the contractor I did my site placement with;

- What is the possibility of the MoD providing temporary or transit accommodation to the contracted workforce?

By way of background the site is a secure, MoD site, with years – possibly decades of upcoming works. Security caveats prevent non-UK or non-NATO Allied Nation citizens from accessing site, even if escorted. This can drastically reduce the availability of local workforce, especially Gen. Ops. This then coupled with the higher levels of QC and QA of the works it can mean that contractors have to be brought in from around the country and they need somewhere to stay.

Accommodation along the M4 corridor is notoriously expensive, and when considering the transient nature of work on site, landlords are reticent to take tenants who are unsure at the sign of lease how long they’ll be there for. It seems the industry standard response is hotels – but these come at a price, which is then in turn passed onto the Client, in the tenders.

One request was for the possibility for the Client, a subsidiary within the MoD, to provide some sort of accommodation. This then gives an assurance of accommodation costs and availability for contractor, and the Client then doesn’t get “stung” by hidden Operation costs. This wouldn’t be a case of using spare accommodation in Messes or SLA blocks (as if enough existed anyway!) but a contractor “village” of semi-permanent structures.

It does perhaps raise, at least at the start, more problems than it solves; Who pays all the costs? Who has overall management? How are rates set? Who has ultimate say over availability and will smaller subbies get muscled out? What if it starts to operate at a loss? Under CDM doesn’t welfare provision from Client end at the site gate? Plus many, many more.

I can’t think of any examples within the MoD where contractors are housed by the MoD – aside from on Operations or overseas exercises. Plus, it could set a dangerous precedent – will contractors now expect accommodation on secure sites? I believe other sites may have a similar context, perhaps the like of Hinkley and was curious what others have seen and their thoughts.

My gut feeling would be typically martial – “Suck it up/choose your trade/if you don’t like it sign off etc.” but wondered if there may be some logic here – maybe not 100% of the accommodation but perhaps enough so that projects aren’t adversely hampered by a lack of resource, owing to staff not having anywhere to stay? Or possibly, are contractors unfairly driving up the rental market in the local areas?

(Image from https://www.santacruzsentinel.com/2021/05/12/cartoonists-take-housing-shortage/)

Waiting vs Wasting Time

Not sure if anyone else has seen this one site but after several months of Phase 2 and establishing oneself in the mix I’ve come to the revelation that often RMAS DS were indeed right; “Any decision is better than none”.

All too often works or indeed a whole section have been delayed and the opening defence seems to be, “I was waiting for…”

Granted in a context of multi-million pound projects and one of the most dangerous industries, a pause for thought is certainly warranted and shooting from the hip can cause more problems than it solves. However with the assumed project management tools and programming on site the vast majority of decisions can be made with the prescribed intent in mind and a desire to push onward – or suffer additional costs through standing time, much less missed gateway reviews or payments.

What initially baffled me was that no one wanted to be the one to make the decision, and therefore be accountable, but would much rather wait and see, hoping someone else would, and then jumping on the bandwagon after. Perhaps it is from a military mindset where critical decision making is encouraged and reinforced, but I wondered if this was seen industry wide or is just a culture on this site? Clearly some critical decisions remain the purview of key (and legally binding) individuals however even a decision as little as deciding how much concrete could be required for a routine pour was often led by a group discussion, resulting in whatever the most senior person decided as the clock struck 1730.

It doesn’t appear to be from a lack of understanding or engineering ability as when I’ve discussed issues with other engineering team members they know what they want to do and how to do it, but seem to fail at the final “execute” hurdle. Nor does it seem to stem from a lack of confidence in their abilities. It would seem the overriding fear is that they fail to make the “perfect choice” and end up costing a few pounds more. Stranger still the maxim of an 80% plan executed now vs 100% plan 5 mins late fell on deaf ears (Replied with the “Why not just wait for the 100% plan?”…).

Perhaps cash really is king and one’s worth to a project is directly measured in how much they’ve cost the project?

A cursory article search gives a brief overview and not unsurprisingly, delays are more often than not attributed to waiting for others.

(Construction Workers Waiting at the Job Site Saps Productivity and Profits (trekkergroup.com))

Curious to hear other’s experiences and what the industry driver could be?

(Image from https://www.trekkergroup.com/construction-workers-waiting-at-the-job-site-saps-productivity-and-profits/ published 31 Jul 2018, Trekker Group, accessed 07 Nov 2023).

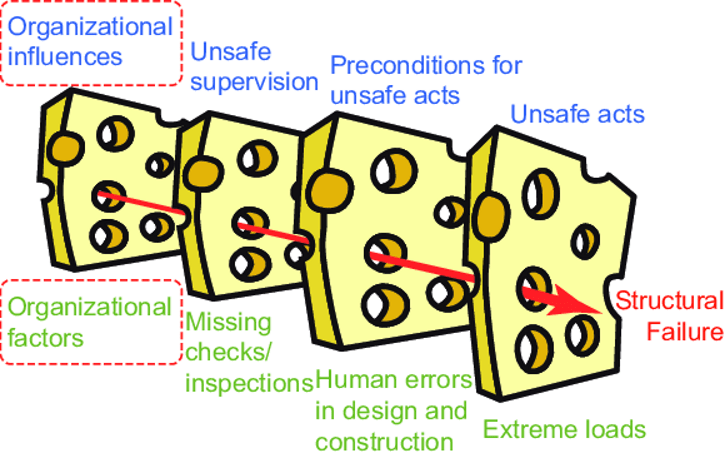

Smiling Assassin or Shrewd Business Practice?

After several months and now experience of several sub-contractors (and then sub-sub, sub-sub-sub ad infinitum…) I thought to reflect on a few observations I’ve found from the world of civilian business practice. As graduates of the esteemed RMA Sandhurst , we live by the Values and Standards, drilled into us from day one to the point that personality is surgically removed and replaced with a code of conduct – I find it strange that it seems such a code of honour can be more negotiable in industry.

Now to be clear, I have not witnessed anything outright illegal or amoral but perhaps a few instances of “collaboration” which appears in conflict of the NEC approach where one party may mislead another through varying versions of the same truths, revealed at carefully stage managed points in time. This has come at increased surprise to me as any contractor on site must be, as a minimum BPSS vetted if not SC, and so come withs a modicum of implied trustworthiness.

An example –

During Client inspection of concreting works where tolerances were tight (-0/+5mm on plan). It was known by a subbie (and sub-subbie) that they were just over, by 1mm. The decision was made, through some implied comms and impressive framing of the problem that we were all better off if the client was led to believe that the slab was on tolerance and the offending non-conformity was shaved off by the night shift to achieve tolerance – as if it had never happened. My question was this;

“Why not declare the non-conformity in good faith but also how you plan to remediate and keep the client happy that we’re a diligent contractor?” (Or words to that effect…)

The answer, whilst simple, seemed almost a lie of omission;

“Paperwork”

I can see the pragmatism of such an approach where hours have been saved by removing the need to submit TQs or NCRs and the bureaucratic process therein. Does integrity have a price? My gut tells me no – one must always do right by the plan and contract, less you end up tangled in a web of lies. Apart from patting myself on the back for the DS answer, it did raise another thought – at the root of this, is it not a slippery slope where there may be other dangers lying beneath? Errors compounding errors (think of the Swiss cheese risk model). Thoughts that were shrugged off by the majority of project staff.

Perhaps I have been lost in the woods too long and suffer from institutionalised naivety but I wonder if others have experienced similar?

(Image From: Ren, Xin & Terwel, Karel & Nikolic, Igor & Gelder, P.H.A.J.M.. (2019). An Agent-based Model to Evaluate Influences on Structural Reliability by Human and Organizational Factors.

Conference: Proceedings of the 29th European Safety and Reliability Conference

Grasscrete – Paving the way to a sustainable future?

Recently, whilst working on a small access road I was introduced to what I thought was a novel, sustainable and simple paving solution – Grasscrete. After a cursory Google search, it transpires that it has been in existence since the 1970s- and indeed some of these uses are still standing. So what is it? And has anyone come across this before?

Simply put, it is a permeable pavement made up of recycled plastic formers and some steel mesh. Once installed some configurations claim to be able to carry weights of ~40T and use approximately 50% less concrete, with no need for active drainage. Relatively simple to assemble one can see why it would be attractive to a customer such as the MoD:

Less concrete means less water, less cement and ultimately less logistics – usually a major consideration when operating in austere environments.

Resistant to differential settlement – Acting as a monolithic slab, loads are uniformly distributed.

With much less run-off, grasscrete is more resistant to storms and stormwater run-off, not requiring active drainage.

Much more durable for expedient roadways and even HLSs for expeditionary theatre entry.

So what are the downsides?

More expensive than standard RC slabs

Plastic formers can be fragile – especially if left in hot temperatures or direct sun.

Lateral forces, especially from heavier vehicles braking/accelerating, may crush the narrower sections of the voids.

Rebar is at more risk from corrosion, minimum cover – especially if voids are filled with soil rather than quick draining gravel.

Whilst it may seem that I’m taking a commission from Grasscrete (c), perhaps Grasscrete/permeable pavements are something the Corps could look at? Whilst not structural and worth a TMR or two on its feasibility, I thought I’d sow the seed on this one…

I’d be keen to see if anyone else out there has seen this before and perhaps why its not been rolled out more often, especially for less trafficked areas/access roads etc. Without getting too far into the weeds…