Archive

Flexible Working

Just wanted to start a discussion on how the construction industry will change as a result of Covid-19. Arup have just made a big announcement about global flexible working, 3 days in the office a week and flexible hours. Allowing employees to work their 7.5 hours a day when it suits them but facilitating crucial collaborative work with teams coming into the office. There are many pros and cons to flexi working but I quite like the idea of this mix and it will be interesting to see how it plays out. Some other thoughts on flexi working:

- Time in the office is really important for developing junior engineers.

- Companies that do not offer flexi working may loose out as people seek roles in companies with a flexi policy.

- Line management of individuals is key to ensure that work patterns meet team and project outcomes.

Another area of interest is how construction firms can adapt to offer roles to people with disabilities. I have conducted a site visit from the design office with a person who uses a walking cane. He drove to the visit and the whole site was accessible due to AliMak lifts between levels (it was a tunnel site) and a few stairs he could manage here and there, see image below. This is particularly pertinent for design offices where people are employed for their brains! He is an Associate Principal with 20 years experience and a technical leader in retaining structures. Arup have been named in the Valuable 500 a global movement putting disability on the business leadership agenda. A campaign to get 500 national and multinational, private sector corporations to be the tipping-point for change and help unlock the social and economic value of people living with disabilities across the world. Because the potential of 1.3 billion should not be ignored.

Arup makes flexible working permanent for UK staff | Construction Enquirer News

Train Spotting

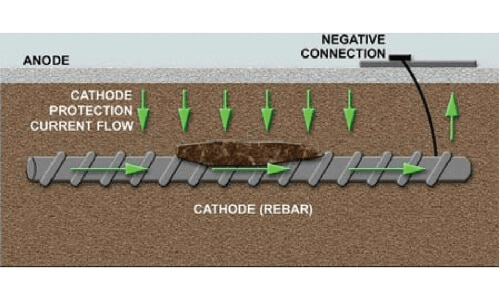

Now that I am officially into trains, or at least have been involved in metro, heavy rail and light rail projects, I wanted to write a quick blog about stray currents. Any current that leaks from the rails and conducts through any path, other than the dedicated return path, is known as stray traction current. As can be seen below stray current moves through the ground, ground water and potentially through surrounding structures.

Why this is important for civils, mech and elec? Corrosion. Whether you are designing and constructing the tunnels for the track to run through, station services and signalling, substations which power the rail and surrounding utilities protection against stray current will need to be factored into your design. Remember the school science experiment with a battery and beaker of electrolyte? Build a rail system and you have one big experiment, only now the corrosion will disintegrate your utilities pipe or the steel reinforcement in your concrete rather than the little piece of metal in the lab.

An electrolysis desktop study is used to identify the measures that should be taken to ensure stray traction current does not present a corrosion hazard to a proposed development. There are 4 key protection measures;

- The installation of heavy plastic membrane under (or behind) all reinforced concrete slabs, metallic platforms/gratings, piers/piles and metallic posts/bollards to electrically isolate from soil and the stray currents.

- Any steel reinforced piers/piles and metallic posts/bollards to be concrete grout encased.

- The use of plastic, rather than metallic, in-ground pipework where possible. In the event buried metallic pipework and/or cables are installed within the site, installation within sealed non-metallic conduit is recommended.

- The use of minimum 32MPa, high cover (min 50mm) concrete to limit moisture penetration to the embedded steel.

Infrastructure has a 100 year design life, beyond that of the measures listed above therefore cathodic protection is installed. Reinforcement bars are welded together to generate a loop through the structure. Generally two loops are created (redundancy) and tested for continuity prior to concrete being poured (site engineers ITP quality checks). An electrolysis point is installed at the surface of the concrete and a sacrificial anode can be attached.

Anyhow a little insight into stray currents and corrosion protection. I had never heard of this prior to arriving on site. Has anyone else had any experience?

The Construction Playbook

Further to Jordan’s post. Another piece of signposting for essential industry reading. In December the UK Govt launched the Construction Playbook in order to help make sure Govt civil engineering projects, particularly infrastructure, are delivered in a more sustainable way and on time.

Government Guidance on sourcing and contracting public works projects and programmes.

Ten min intro video here: The Plan To Change Construction – YouTube

Green loans

3 min read. I came across this article and thought it may spark some interest…

The initial stage of Canberra’s light rail network today became the first Australian transport public-private partnership to execute a green loan.

Canberra Metro has partnered with the ACT Government to deliver award-winning, frequent, efficient and sustainable light rail services along the stage one alignment from Gungahlin to Civic.

Canberra Metro is delighted to announce that it refinanced the $280 million debt facility with a Green Loan with Climate Bond Initiative certification under the Low Carbon Transport Criteria.

This is a significant achievement for not only the project, but for the ACT Government, Canberra Metro and its owners (John Holland, Pacific Partnerships (a member of the CIMIC Group), Aberdeen Standard Investments and Mitsubishi Corporation). It recognises the significance of the first stage of light rail in its ongoing contribution to Canberra’s sustainability.

The project incorporated sustainability principles during design and construction and is now running on 100% renewable electricity and utilising environmentally friendly measures across its operation. The green loan has been issued in accordance with the Asia Pacific Loan Market Association’s green loan principles.

Categories that Canberra Metro qualified for the green loan under include renewable energy, energy efficiency, pollution prevention and control, clean transportation, sustainable water and wastewater management and environmentally sustainable management of living natural resources and land use.

In obtaining the Green Loan, Canberra Metro was assisted by our Financial Advisor and Green Structuring Advisor MUFG, our Green Loan Co-Ordinators, ANZ and CBA and our Mandated Lead Arranger banks ANZ, CBA, ING, Mizuho, NAB and SMBC.

A green loan is any type of loan instrument made available to eligible ‘green projects’. A green project may include renewable energy, energy efficiency, climate change adaptation and green buildings that meet regional, national or internationally recognised standards or certifications.

In the UK we are already familiar with loans or grants toward improved home insultation or installation of solar power. Green loans are also issued in Australia for private and commercial residential developments to boost construction of energy-efficient homes and help reduce household emissions. So whilst BREEAM sets the guidelines for assessing sustainable buildings, some banks have now started to create their own criteria. The goals of these initiatives are to build climate resilience within the banking system, as well as to raise authorised institutions’ awareness of climate risks and broader sustainability issues. In my opinion this could further drive the sustainability requirement from a client which in turn will be felt by the engineer. An interesting prospect for the future.

My piles

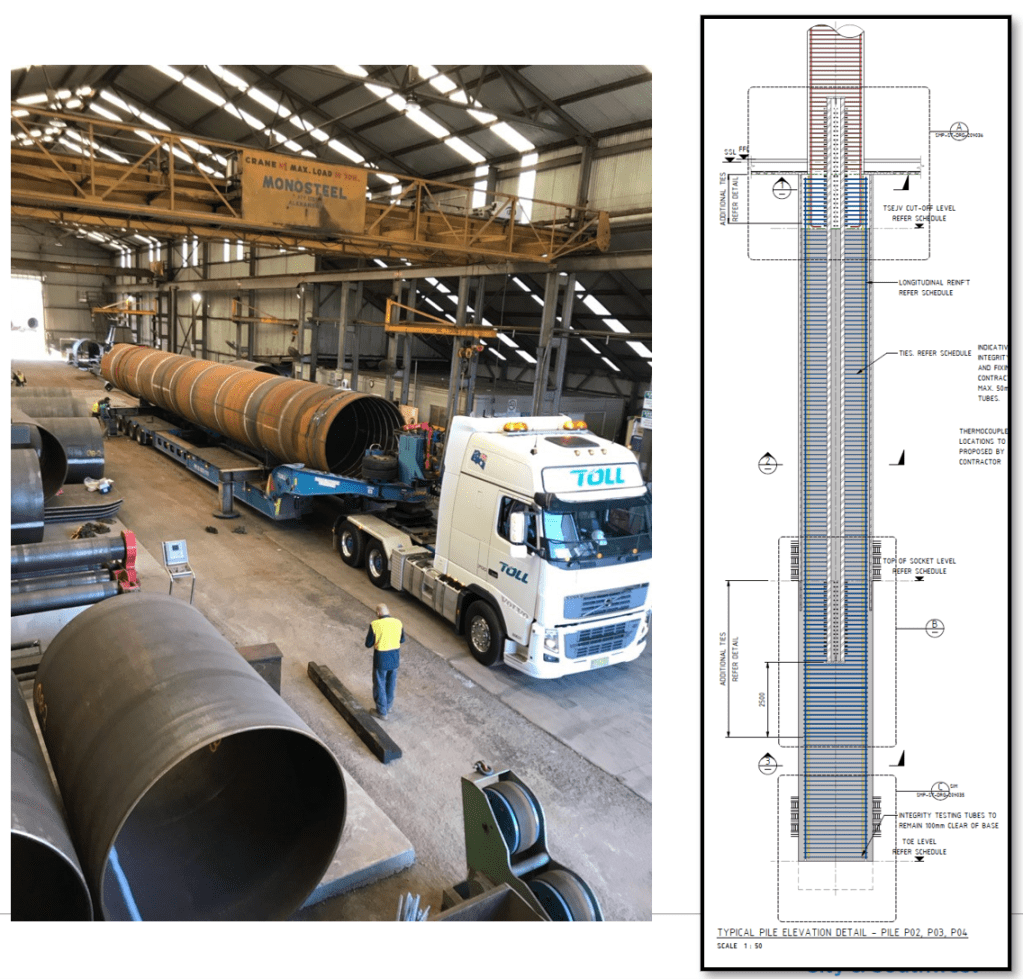

The Tunneling and Station Excavation contract at Martin Place includes the construction of 14 steel reinforced concrete piles. Each pile has a steel sleeve (max 24.1m – approx. 56t) and then a 50mm wide void to the surrounding rock for seismic loading. Three of the piles have a steel plunge column (max 29.6m long – approx. 40t) and the rest have a steel reinforcement cage installed in 3-4 spliced sections. 60MPa concrete was poured in each column using a tremie pipe.

The piles were cored using a BG40 Piling Rig and installed in 2019 prior to my arrival in Sydney however I have been in charge of trimming and ‘finishing’ the piles ready for handover to the follow on contractor this month. My scope of works and assessment of the drawings raised two terms I was unfamiliar with: CSL and TIP. 5 piles were tested for CSL and TIP and I now need to grout the CSL tubes…what are they?

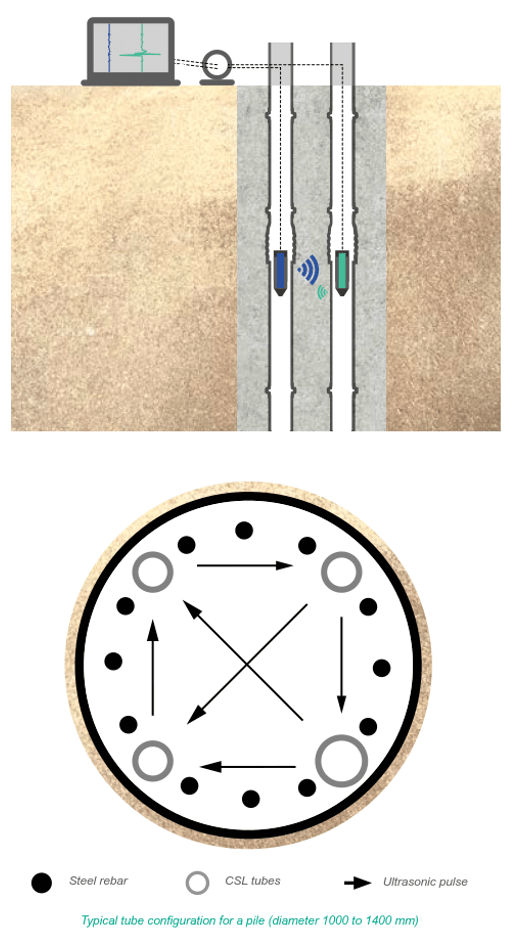

Thermal Integrity Profiling (TIP)

What. A non-destructive testing method to evaluate the integrity of concrete foundations.

How.

- Place sacrificial thermal monitors along the full length of the pile, attached to the longitudinal steel reinforcement.

- Connect wire to data loggers at the top of the pile.

- Start logging prior to the concrete pour and measure the heat generated either throughout the cement hydration process or at a set time prior to the expected peak curing temperature.

- Compare the predicted and observed thermal profile.

Why. Quality assurance to prove the quality of both a piles cross-section and entire length. Deviations from the expected thermal profile indicate defects. Cool areas, shortage of concrete, i.e. necking or inclusions. Warmer areas, excess concrete, i.e. bulging and over pour. Analysis of the thermal profile can also assess if the reinforcing cage is properly aligned and centered. TIP testing is usually complete with 72 hours of a pile being cast and is the first test that can indicate in issue with a pile.

*Note, do not google TIP for piles, you end up on an NHS self-help page.

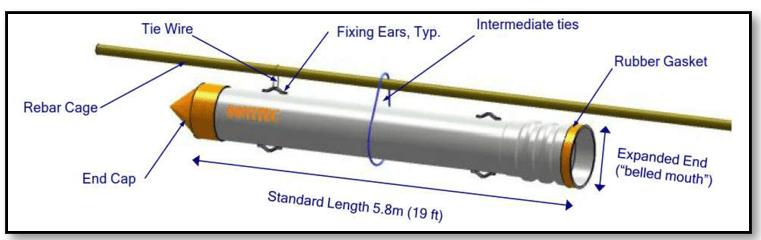

Cross Hole Sonic Logging (CSL)

What. A non destructive test method to test for the structural integrity of a pile. Sound concrete is only checked inside of the steel reinforcement cage and not the concrete cover. Also known as cross hole acoustic testing.

How.

- Steel access tubes are installed inside the fabricated steel reo cage. In this instance every 300mm around the diameter. Check straightness, end caps installed, intermediate sections secured, bottom and top caps fitted. (Often CSL tubes are prefabricated by the cage supplier).

- Post installation, tubes will be filled with water.

- Post concreting, tubes will be checked for any blockage and this will be carried out by lowering weighted tape.

- Piles will be tested after 3 or 7 days post concreting and before 28days.

-Sound source lowered into a tube.

-Sensor lowered into the opposite tube to the same depth.

-Sonic pulse emitted. Relative energy, waveform and differential time are recorded, and logged.

-Procedure is repeated at regular intervals throughout the pile and then mapped. - Combination of graphs compared to identify flaws in the concrete.

- Once testing is complete and piles accepted by designers, the tubes will be grouted with 65MPa grout.

So there we go. Now I knew the purpose of the wires and tubes sticking out of the top of the pile I was looking at!

Due to access and programme a number of the piles had not been finished at the time of installation. Half had been covered up under steel plates across site for over 6 months and now needed to be dug out, 2m of sacrificial poor concrete hammered out and then have the remaining reo tied prior to inspection and sign off from the designer and IC. A few photos below of the fun that entailed and some points for discussion.

- Who conducts the TIP and CSL testing? Ours was done by the piling subcontractor, Bauer.

- Has anyone used the proper brush gaskets to maintain a clear void? For some reason despite being part of the initial planning we ended up using pool noodles!

- H&S for the subcontractor hammering inside the pile. We had to use a tripod and harness for emergency evacuation. Monitoring of live edges and enforced pairs working with a spotter at the top of the pile.

- The pile shall be trimmed to a specified cut off level leaving only sound, well compacted concrete on the surface of the pile head (as per the ITP). ‘Sound concrete’ at the pile trim level was determined by visual inspection of adequate aggregate and a few hits with a hammer to check none cracked away. This appears to me rather informal as opposed to a qualitative physical approach such as Schmidt Hammer?

Super Tunnel

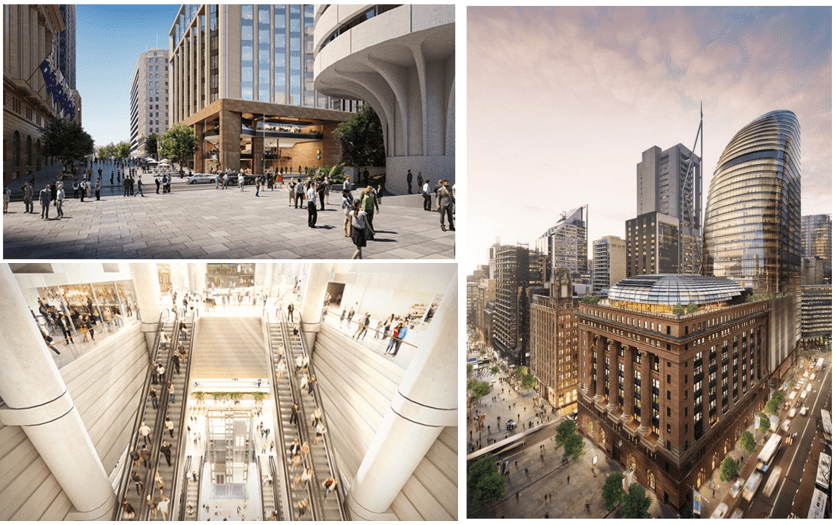

Al, I will raise your UK’s busiest airport series with Australia’s biggest infrastructure project. No starring role for me but tonight (Wednesday) my site at Martin Place gets some good coverage. I have recently been cross bracing and propping the temporary pedestrian bridge they install as we are now excavating underneath it.

https://www.sbs.com.au/ondemand/program/sydneys-super-tunnel

Might need a VPN to get it to work in the UK but there are a few clips on YouTube as well.

D’ya like dags?

Before all the E&Ms get carried away blogging lets talk about concrete.

Well, the answer if you are an Irish concrete pump operator is no. Despite the Archimedes screw inside a mixer truck a small amount of concrete always remains inside, especially in drum mixers. You can wash the truck out, run water through the drum while it rotates and even pressure-wash the inside. But some concrete residue is always left. And it dries. The next trip a little more is left. And it dries. Over time, this becomes a problem, reducing the volume of the mixer and its capacity.

The process is expedited when a concrete mixer truck driver does not wash out the machine properly between loads and aggregate and chunks of concrete are left to cure in the drum. Once hardened, and a new batch is being spun in the machine at full tilt, the old lumps of concrete can work loose and get fed into your 47m concrete boom pump at 1am. A dag as it turns out is a lump of old, hardened concrete. Pondering this new technical term and having had a quick google, turns out it is defined as ‘a lock of wool matted with dung hanging from the hindquarters of a sheep’.

The pump struggled as it passed through the hopper – we dropped the hopper but the problem persisted. Not knowing how large the ‘dag’ was and hoping it would break up in the line the operator continued pumping concrete only for it to block the 5” to 4” reducer pipe at the bottom of the boom. We retracted the boom, removed the reducer and found the dag! Weighing about 3kg and full of 30mm aggregate – we were pouring a 10mm mix.

The ‘dag’ delayed the pour by an hour. As a site engineer you control the batching times of concrete from the plant and arrival to site. I had to return a near full load (7m3) truck to the batching plant as it got too old for us to use (over two hours). Hot, dry, stiff concrete won’t pump either. Touch the side of the mixer truck and you can feel how old the concrete is. The pump operator will always try and add water, even to a fresh batch, but as a quick rule of thumb – for every 2cm of slump you gain it will reduce the 28 day strength by 3-4 MPa. Mercifully the next load came swiftly and with a lot of needle and form vibrating we avoided forming a cold joint in the pour.

Our concrete supplier have a really handy guide for ordering pre mixed concrete which I would recommend a quick read. Doesn’t mention dags though…

Polystyrene Formwork

Some pent up blogs to follow now that I have permission from the project office to blog. * DISCLAIMER. The contents of this blog have been made available to the author for academic purpose and are not to be disclosed other than for academic use.

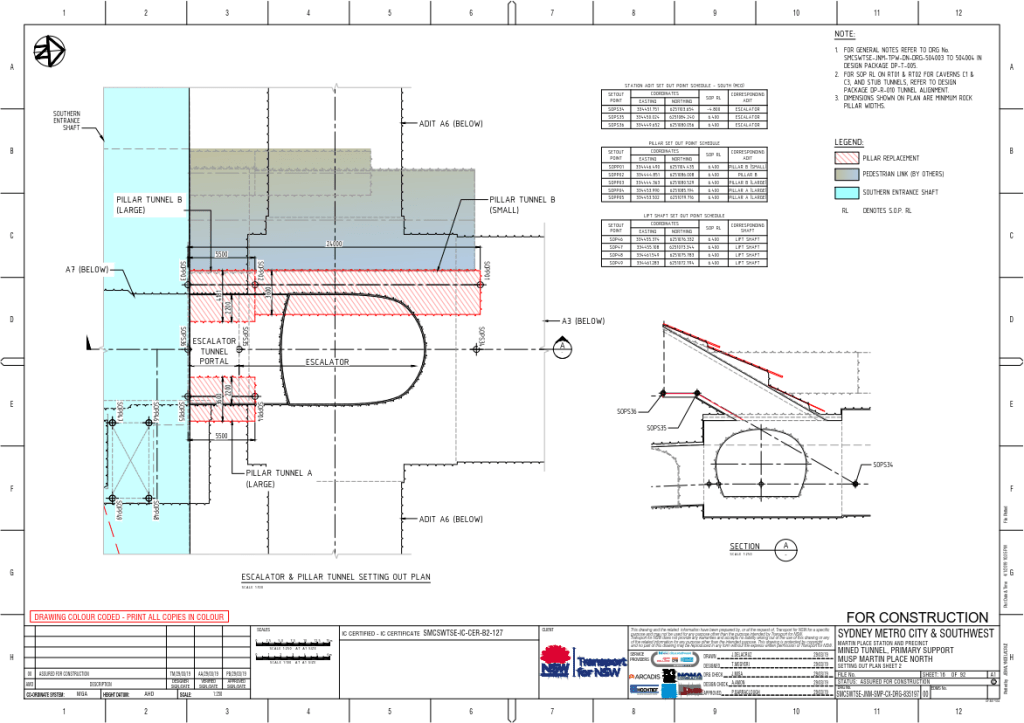

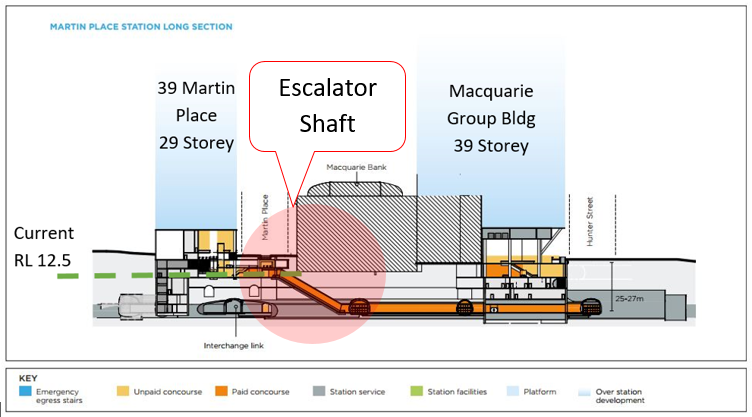

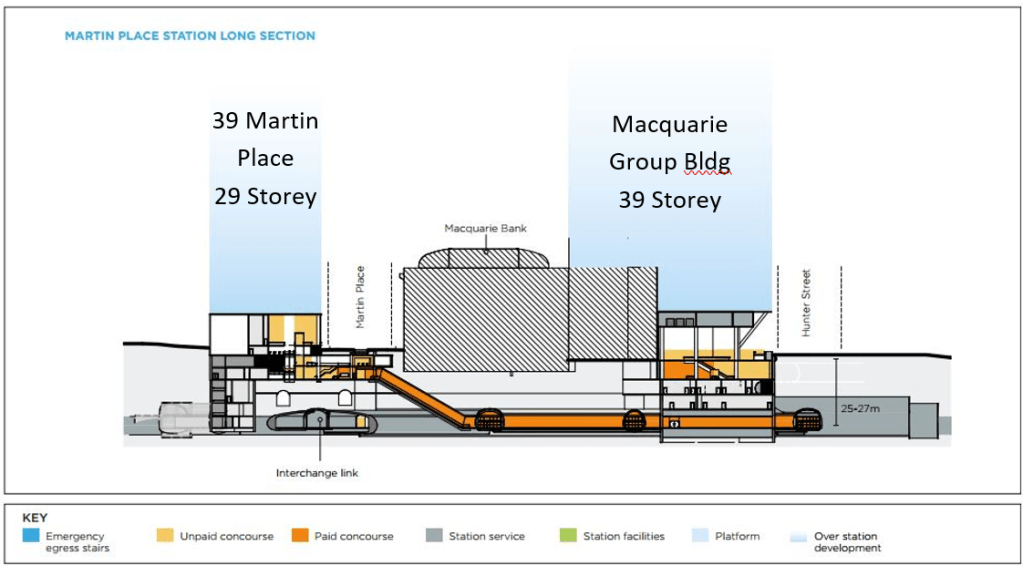

The Martin Place Metro Station site has two deep excavations either side of Macquarie Bank, a heritage building (Australia’s equivalent of the Bank of England and looks a bit like Gringots!). As per my last blog, the North Site has since been purchased by the bank, as has the over station development rights for the South Site. Long and short of it we have tunnelled beneath an important historic landmark and now need to excavate a diagonal escalator shaft from -10m below the front door, back underneath the bank and into the station cavern below. Best not to crack any of the marble…

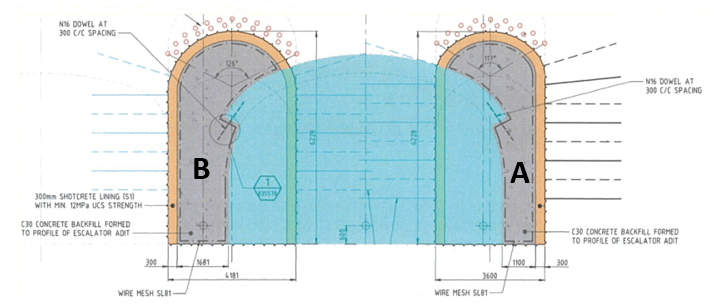

To sure up the Hawkesbury Sandstone rock beneath the bank and prevent settlement the designer has proposed three large reinforced concrete pillars be installed beneath the bank. Pillars A and B have been installed since I have been on site. The requirement for Pillar C is yet to be determined based on monitoring the bank buildings response. Pillar C could be constructed in the future by the follow on contractor, Lendlease when they start the tunnel and station fit out contract early 2021.

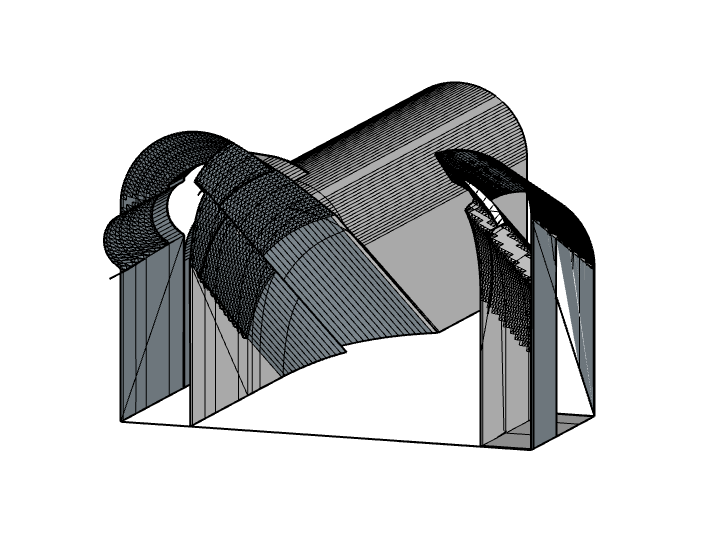

The profile of the escalator tunnel is constant as the portal descends. At the tunnel opening and throughout the descent there is a portion to be excavated which overlaps with the pillar tunnels leading to a challenging shape. Approximately half of each pillar tunnel will overlap the escalator tunnel portal. The notches at either side are critical for the installation of lattice girders, providing temporary support as fresh rock is cut, prior to temporary support (lattice and shotcrete) and the final reinforced concrete lining. A derivative of the New Austrian Tunneling Method. The challenge was how to create such a complex shape.

1. Change the design;

- Alter the profile of the escalator tunnel crown so that it is consistent for the whole profile

- Change the profile of the lattice girder support of the escalator tunnel crown and where they sit on the side walls.

These ideas were briefly explored by the senior site engineer however the time it would have taken to push through the RFI process and redesign would have caused delays. We have had to accept the challenging shape and come up with a temporary works design solution for the formwork.

2. Change the method;

- Pour half of the pillar with the notch space created by formwork

- Pour half of the pillar and fill in the notch or block it out

- Pour the whole tunnel with reinforcement through half and create a block out notch within the pour

The Formwork, Reo, Pour (FRP) Senior Engineer and Shaft Senior Engineers did a quick appraisal and cost for each scheme. We have a very experienced concrete subcontractor on site (Kenny’s) and they also could not find a cost effective formwork. In the end we opted for the whole pillar pour with a block out.

3. Selection of materials for a block out;

- High Density Cardboard had been used as a block out elsewhere on site earlier in the project – needless to say it didn’t work as cardboard is porous it turned to mush and did not prevent the ingress of cement and leave the desired shape.

- Wood creates a splinter hazard when hammered out and could have caused shrink/swell issues with moisture. It was also relatively heavy to manoeuvre into position within the tight reinforcement cage. The weight of wood also made it difficult to create an internal supporting structure within the form. It was have been hard to form a seal between sections of wood too.

- Polystyrene. Create a custom shape blockout to fill the entire void within the form. Light weight, easy to work with, can be purchased to exact size and dimensions.

The polystyrene block out worked really well however the choice to pour the entire cross section of the pillar caused a one week delay to the programme during excavation as the 50MPa concrete was difficult to break out. Two unforeseen secondary effects also occurred. Excavation in sandstone generates a lot of silica dust and water suppression is vital. Pumps operate daily to remove the slurry and water from the blinding slab. Broken segments of polystyrene and the tiny balls within it subsequently blocked and damaged two pumps and polystyrene still litters the site nearly two months since it was dug out. Secondly, the spoil disposal subcontractor picked up on the polystyrene content of waste leaving site. Virgin excavated natural material (just the rock) costs $29/tonne. General Solid Waste Recyclable costs $115/tonne. For the rest of the 320m3 (7680 tonne) of excavation the spoil was often reclassified as GSWR. Not all loads were deemed GSWR but those that were costed the site an additional $15,000. Perhaps the complex formwork would have been cheaper after all.

Monopoly Rule No. 8 – Once you own all the properties of the same colour you may develop them…

Board game rules apply in Sydney CBD – a benefit to the community chest?

My first few blogs should be approved by the end of the week but in the meantime, this is public knowledge and interesting.

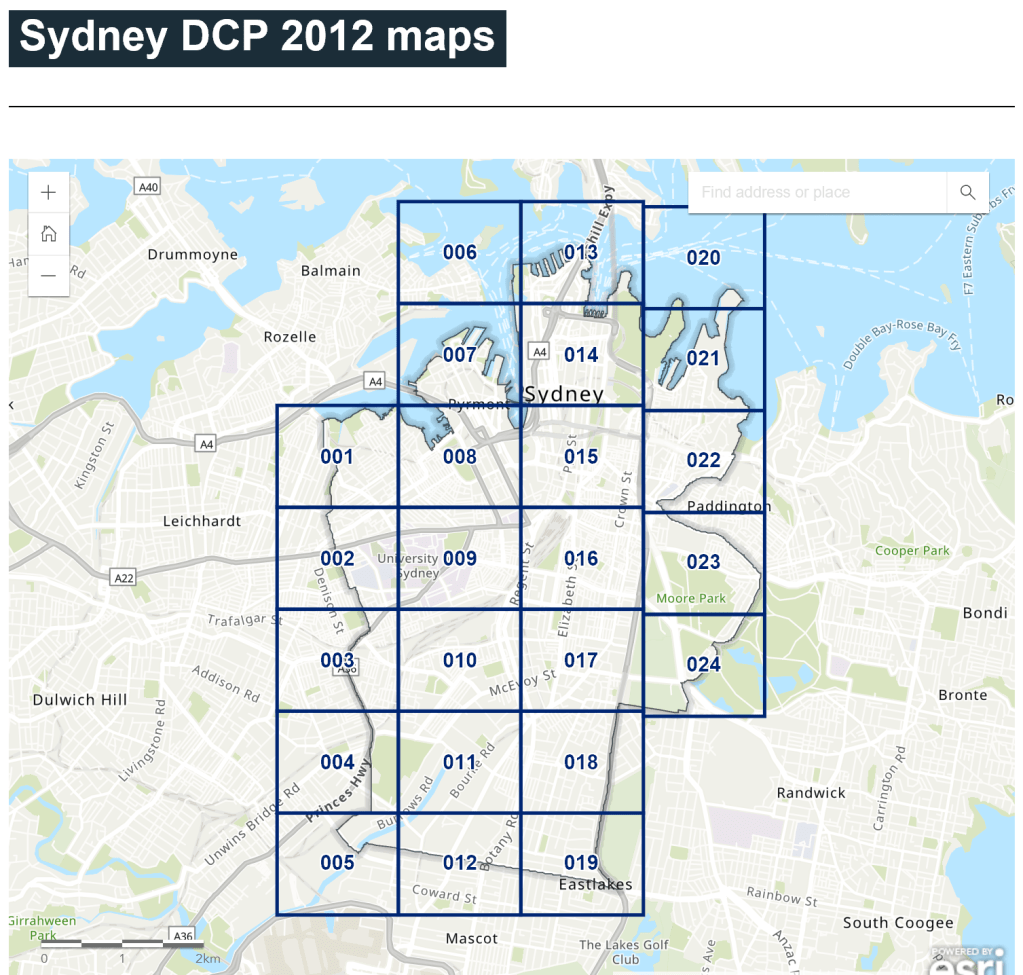

The City of Sydney or the Central Sydney Planning Committee is the consent authority for development other than major projects; there are currently 16 major projects (Figure 1), plus an additional 19 development control plans, dictated by area (Figure 2).

Now that you can picture the board. In square 014 is my current project, Sydney Metro Martin Place Station. Martin Place is a pedestrian mall in the middle of the CBD and has been described as the “civic heart” of the city as it is home to the Sydney General Post Office, the Seven Television Network News Centre, Cenotaph and the State Savings Bank building. As an iconic, cultural and historic area of the city planning permission is limited to 20 storeys. That is, unless, you own all the properties on the block. In which case the permitted number of storeys (and thus sqm of new office space) can be spread amongst the properties on the block.

Fig 3. Satellite image of Martin Place and the heritage bank.

Macquarie Group is a financial services provider who own the heritage listed State Savings Bank building at the Centre of Martin Place. The new metro station tunnels beneath the bank and the station entrances are currently being excavated to the North and South (Figure 3). Work on site began in January 2018. By March that year Macquarie Group submitted an unsolicited proposal to the Government of New South Wales for two Over Station Developments (OSD). The towers would be predominately commercial, with Macquarie Group occupying both. The concept for the north tower was more than 40-storeys with a podium to be integrated with the existing 50 Martin Place (bank), while the south tower was to be more than 28 storeys.

In May 2018, a site-specific amendment was made to the Sydney Local Environment Plan. The new planning provisions for the Martin Place Metro Precinct permitted a larger building envelope for the South site. The State Savings Building is only 10 storeys high yet by planning controls it could be 20. Thus, by owning all the properties on the block Macquarie Group were able to exploit a loophole and by September an agreement had been made for Macquarie to deliver the new station and two new towers by 2024, along with construction partner Lendlease. The North tower will be 39 storeys and the South will stand at 29 storeys. Transferring their available storeys (houses or hotels!) to a neighbouring property (Figure 4).

Community Chest gained $355 million as the Government sold the air rights above the new metro station. Macquarie will spend a further $637 million on the construction and delivery of the new underground Martin Place station integrated with a retail and recreational precinct, two new office towers and the existing Martin Place railway station.

Cost of the new station $378.6 million

Fee paid by Macquarie $355 million

Cost to the Taxpayer $23 million

Once the new buildings are complete in 2024, Macquarie is also likely to make another payment to the government to reflect the increased value of the land; as the world’s largest infrastructure asset manager, they should know. Macquarie now own the rights to one of the most coveted corporate addresses in Sydney. New metro trains are due to deliver thousands of customers from the suburbs straight to their new towers every four minutes. By 2056, New South Wales will have more than 12 million residents and Sydney is predicted to become a global city, similar in size to London or New York. Time will tell whether Macquarie’s investment will pay dividends, but I have a feeling owning the site of Sydney’s largest public transport hub will mean that the bank inevitably wins.

Government Approved Blogging?!

After a week on site at Martin Place Station, Sydney I have an interesting topic (rock reinforcement) for a blog. However, upon approaching my PM, I have been initially advised that all project related comms need to go through the client – Transport for New South Wales. The process can take up to a month or so. Has anyone else had such problems previously? Any advice would be appreciated.

Happy Sunday all.