Archive

Boise, Idaho Steel Portal Frame Collapse

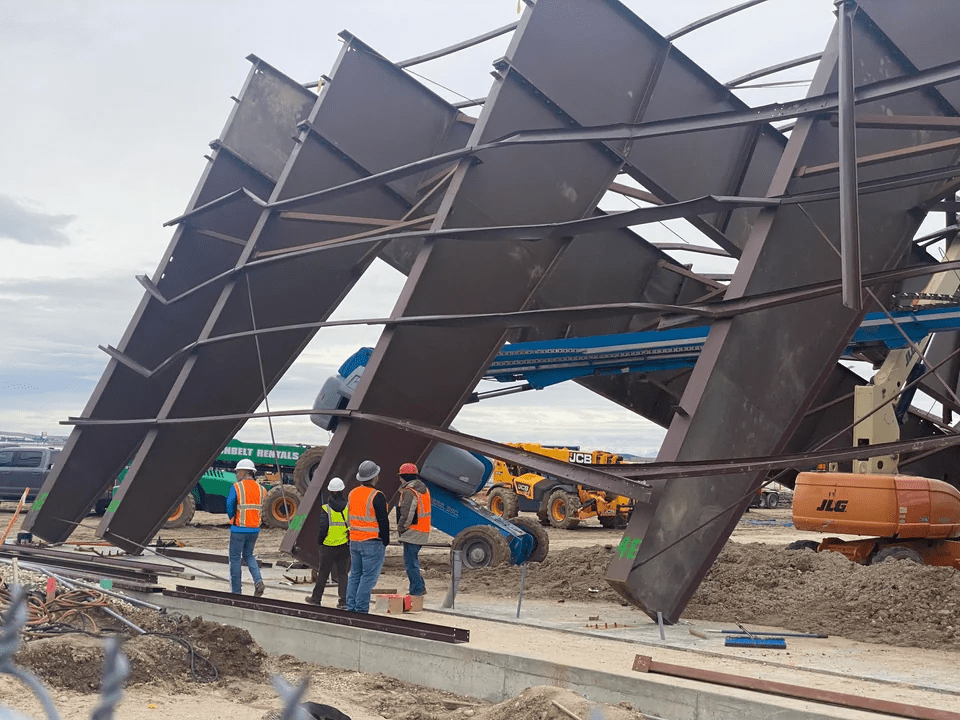

Unsure how broadcast this was back in the UK, but there was a recent significant structural collapse in Boise, Idaho. A steel portal frame under construction collapsed under what appeared to be high winds, resulting in the death of three workers and nine others injured.

The investigation into why the structure collapsed is still ongoing by OSHA, but the information put out so far appears to indicate that high winds, combined with a lack of installed cross-bracing, resulted in the collapse of the structure at the centre, bringing down a supporting crane during a lift.

Whilst a tragedy, I think this can provide some crucial guidance as to the dangers of ignoring methodology, underestimating environmental loads and temporary loads. I’m sure in the finished design that the wind load was dealt with properly by a sufficient bracing system, but it seems that from the trickle of information being released from the site that it was overlooked during the actual method of works. From a recent news article, an individual said “Wind picked up and they were scrambling to install guy wires and cross braces before the collapse. Said the building was making all sort of nasty noises then it was a massive all at once failure.” Even if this was considered in design, the H&S plan for operation was either not substantive enough, or ignored, for the construction to still be operating in high wind. For the site I was on, during the erection of the steel frame, if high winds were recorded, any work on the frame would pause until the wind subsides. This is certainly evident in the UK, with the BCSA (Pub No. 39/05) publishing a guide specifically on the erection of steel frames in windy conditions. If there had been no workers on site during these high winds, it still would have been an expensive collapse, but at least no loss of life would have occurred.

Usurpingly, the principal contractor, Big D Builders, have had a history of safety violations and fines from OSHA. Whether this is just a coincidence or a critical link, I am sure the OSHA report will say.

Certainly relevant for Ex STEEL and the temporary works element for future courses. A morbid lesson that can teach us the importance of H&S plans on site, construction methodology, and most importantly, how temporary works should support a construction to prevent unnecessary deaths.

Further articles on the collapse:

https://www.idahostatesman.com/news/local/community/boise/article284954822.html

Structural Failings on Site – Welch Elementary School

Working with USACE, I get the opportunity to visit different sites to broaden my experience and see various forms of engineering at work. I recently visited the Major George S. Welch Elementary School on Dover Air Force Base, Delaware and was surprised at how badly this construction project had gone.

Construction began in June 2019, with the aim of being open for the 2021 school year in Sept/Oct. With it now being close to 2024, it’s safe to say that the $48 million project has failed to deliver and current estimates put it at a finish date of late 2025/early 2026. The current situation is that no future construction is ongoing, and the principal contractor is going through a corrective process for all issues currently found on site, (estimated over 10,000 deficiencies so far). If they fail to correct these issues within a timeframe that USACE is determining, the contract will be terminated and a re-issuing process will have to be established, a costly and timely exercise that they want to avoid. There have been numerous failings throughout all levels for both USACE as a Govt body ensuring successful delivery on behalf of the client, and the principal contractor, Dobco, Inc. Whilst the project and programme management side have had plenty of issues, I was more interested in the ongoing structural failings of the current shell, as I’d heard that a Special Inspector deemed the site completely unsafe for any future work.

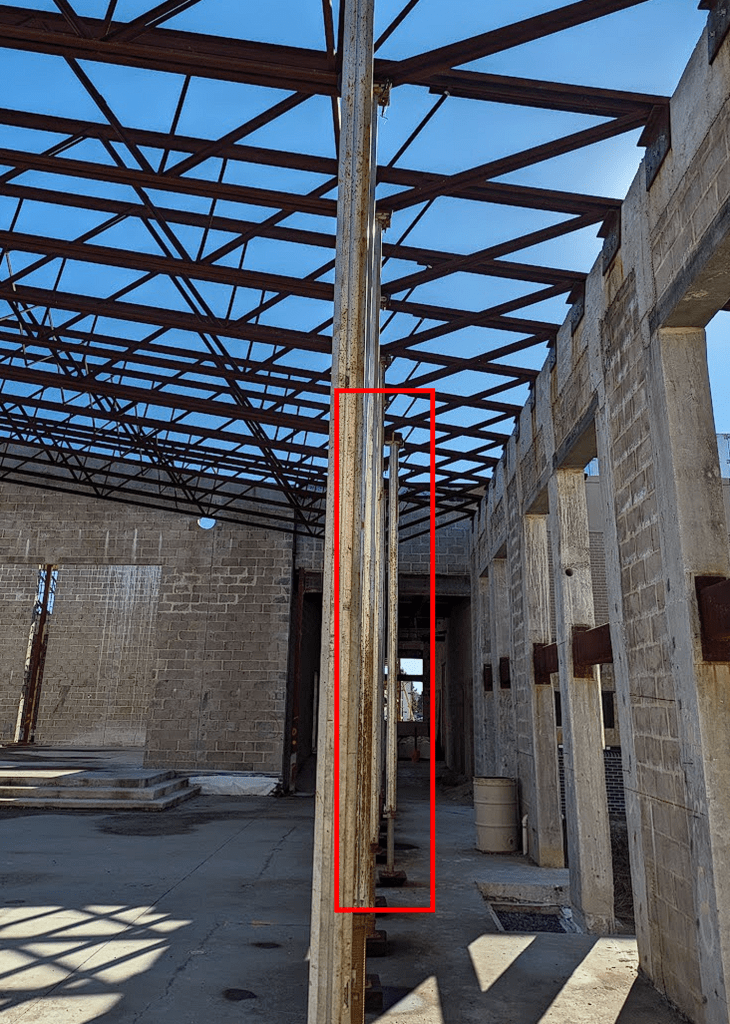

Some of the structural failings were alarming, and I was surprised that they had reached this level with no remediation at all. Unsupported structures, corroded trusses and failed loaded columns was what was immediately visible going into the site. A picture below shows some of the columns that seemed to just have forgotten to have concrete placed at the base? And then to top of it, the contractor failed to provide adequate drainage to the area, resulting in prolonged flooding around the exposed rebar and therefore significant corrosion. I don’t understand this was not spotted on site for such a long period, or if seen, didn’t have any concerns that a concrete column base didn’t have actual concrete in it.

Further up from that column was an unsupported horizontal steel element, what appears to be designed as a restraint for the column’s slenderness but isn’t actually attached. Speaking to the PE there, it seems that the contractor must have sent the fabrication details to the steel supplier, but upon receiving the reduced size element, they just then decided to install it rather than thinking this doesn’t appear to be right. Instead of removing it and fitting it a correctly sized element, their solution was to prop it with timber and concrete the end of the steel beam into the column, clearly without the reinforcement then fitting into the column as designed. A mind-blowing piece of engineering.

There were numerous other structural issues; mis-sized fabricated truss roof elements, meaning the column was out of alignment, changing the load paths and altering the rooms design from originally intended (picture below). Significant cracks on every concrete slab (below), of nearly 10mm wide in some areas, well beyond an allowable tolerance, filled with water, perfect for the upcoming freeze-thaw weather.

I’d often heard about some contractors winging it on site with little understanding of the engineering they are constructing, and a disregard for personal and structural safety, but I didn’t think I would witness such significant failures in person. A lot to gain experience wise, but I can imagine working or overseeing such a site must be an absolute nightmare. Has anyone else experienced such disregard for proper methodology? And if so, is there any likelihood of the contractor redeeming themselves, or is it better to pull the plug on them earlier rather than later?

If anyone is further interested in this site, I can provide more information about the project delivery failures, and I’m due to visit again in January so can see if the site has advanced any further, or most likely, completely collapsed.

Working in the Trenches – OSHA vs HSE

I have had a few difficulties on site when it comes to workers operating in excavations and trenches whilst on attachment in the US. The areas the workers have been in often have slopes that appear near vertical in their cut and what I could class as significant in height. When I have questioned this to the H&S Manager on site, they have stated that support is only required when the excavation or trench is 5 foot (1.5 metres) or more. Access and egress points only need to be placed for 4 foot or more, but still no support is required at this depth. Alternatively, they can be cut back with a step, or at a 45 degree angle dependant on the ground, but this is just as difficult to enforce on site as well. The problem is exacerbated by the following:

- The areas they are often working in is a mixture of a very loose sandy material above a consolidated clay layer; walking near the excavation can often result in slips of the material then falling into the trench.

- Spoil heaps are placed nearby to any excavation, OSHA does not specify a minimum distance, just a ‘safe distance’ judged by a competent person. I’ve often seen this for a spoil heap up to 3m high, less than 2 metres away from a trench. When the competent person is the H&S Manager who classifies 5 foot of unsupported excavation as safe, you can imagine their idea of a ‘safe distance’ when it comes to spoil heaps.

The problem I seem to be having is that if I comment or ask for a trench to be supported, or spoil moved back, I’m simply met with a response that this is per the OSHA requirements. When compared to HSE, they removed the previous 1.2 metre (4 foot) rules as excavation and trench support depends on the ground conditions and other risks. I wish this was the case for OSHA but I’m at a bit of a brick wall when it comes to the H&S Manager. I’ve passed up my concerns to the principal contractor and to my CoC at USACE, but met with the same thing; as long as they are within OSHA guidance the H&S Manager is technically correct. I don’t know about you, but I certainly don’t get the warm fuzzy feeling going into a 5-foot unsupported trench with loose material surrounding me, especially if I’m on my hands and knees working on utilities.

To put it into a statistical perspective, OSHA reported in 2022 that 39 workers were killed in the construction due to trench and excavation collapse (OSHA, 2023). In the UK for the same year, across all worker industries, 12 people were killed by collapses or being trapped (HSE, 2023). This may not even be related to excavations, but no deeper data can be found, but I think it’s easy to conclude that excavation related fatalities are rampant across the US compared to the UK.

Has anyone else encountered something like this before or could offer any professional advice on how to move forward?

Sources: OSHA Excavation Deaths Statistics 2022, more information can be found at https://www.safetyandhealthmagazine.com/articles/23703-trenching-and-excavation?page=1.

HSE Work-related fatal injuries in Great Britain 2022/23, available at https://www.hse.gov.uk/statistics/fatals.htm.

Mast Climbing Platforms – A safer, more efficient form of scaffolding?

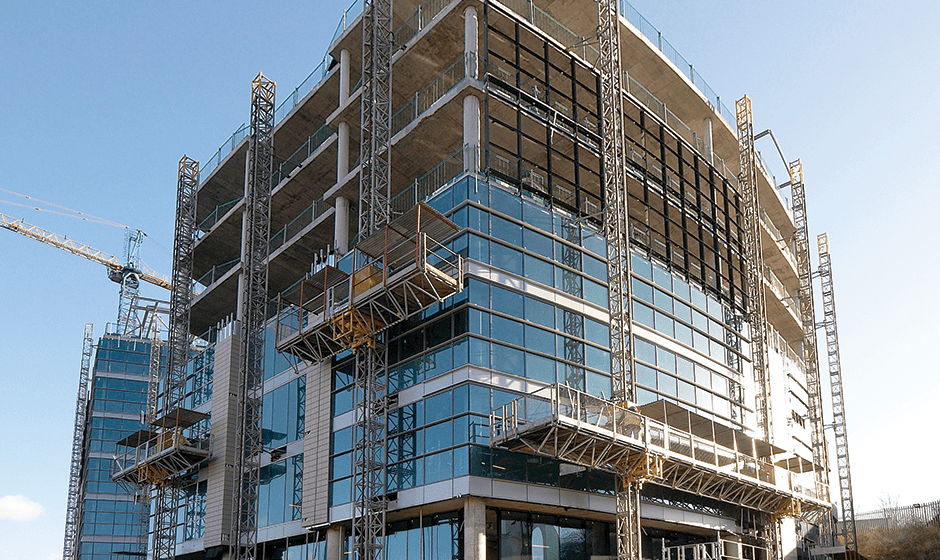

I am currently working on an SOF Operations Centre on Fort Meade, Maryland for USACE, a new project compared to the usual NSA East Campus site that others may be familiar with. We are currently coming out of the foundation stage and moving into the erection of shear walls and beginning the steel structure placement.

Currently on my site in the US, the masonry sub-contractor is erecting the reinforced three-storey shear walls. They have done this in an exceptional timeframe, currently two weeks ahead of their schedule and one of the primary factors they put this down to is the use of the mast climbers, compared to traditional scaffolding. I have attached several images to this post that show the various setups they can be used in, and examples on sites. For those who have never seen them or not noticed them, they are defined as “A powered device consisting of an elevating working platform mounted on a base or chassis and mast, that when erected is capable of supporting personnel, material, equipment and tools on a deck or platform that is capable of traveling vertically in adjustable increments to reach the desired work level (NYC Building Code 2008).“

I have never encountered this in the UK, so this was a new concept for myself and did some quick digging to see if any further advantages, or disadvantages, that come with using mast climbers over scaffolding:

Mast Climbers Benefits:

- Speedy and Efficient: Mast climbers offer a high level of speed and efficiency as they can be adjusted quickly and easily to the required height, and then quickly moved back down to collect materials, or change shift personnel.

- Increased Productivity: Workers can access a larger work area simultaneously, reducing the need for frequent repositioning, at one point I witnessed at least 15 workers simultaneously working on the masonry structure with little overlap. Combined with the space for worktables, productivity in my opinion seemed much greater compared to the B&Cs of the RE…

- Higher Load-bearing Capacity: Mast climbers can support substantial material, personnel, and other necessary loads, making it feasible to transport to the desired height when compared to scaffolding, which can be an arduous process for materials.

- Quick Setup. The masons had two trained personnel that knew how to construct the mast climbers, they then supervised the rest of the workers and checked all necessary connections and motorised components of the system. For a 20m x 30m tower, the setup of the system took only one day. On the BFT Mastclimbing guide, for a 30m façade, they estimate a setup and strip down of 2 days, compared a scaffolding setup of 16 days, and strip down of 14 days. In terms of project time, this is a significant time saver and easy win for any project manager.

- Footprint. On site, I was surprised to see how little space the mast climbers took up when compared to a traditional scaffold support. Additionally, the storage required was arguably less than a scaffold setup for the same façade, as the mast climbing platforms and extensions are stackable. The Superintendent was clearly a big fan of this and is reluctant to go back to traditional scaffolding after this.

- Safety and Workability. Arguably one of the biggest benefits, mast climbers provide fall protection through the barriers. On the interior side, only harnesses are needed when the interior working wall is less then 3 ft, and then the harnesses are simply clipped to the other guard rail. OSHA has published specific guidance on mast climbers, and incidents do occur, with the most common (dismantling collapse, structural overloading and improper fall protection) all associated with improper training and leadership.

Mast Climbers Drawbacks:

- Initial Capital Investment: This is the main drag of the mast climbers; they have a high initial purchase cost for purchase and installation compared to a traditional scaffold that is very cost effective. They can be rentable, but still at a significant cost. The most recent, unbiased article I could find but mast climbers at approximately three times the cost of scaffolding for the same job (https://www.masonrymagazine.com/blog/2018/03/01/mast-climbers-the-latest-and-greatest/). However, if the amount of vertical masonry is significant on the project, could those costs be saved purely through the time gains if in alignment with the clients aims? Or alternatively, when looking at procurement, could going with the more expensive mason that has one of these at their disposal be a more sensible choice compared to the typical lowest bidder (as occurred on my site)?

- Limited Versatility: When compared to scaffolding, they are more suited for projects with relatively flat facades, as they do not adapt particularly well to irregular surfaces like scaffolding does.

- Regular Maintenance Required: Mast climbers require frequent maintenance when compared to scaffolding, and this must be from a certified, trained individual due to the mechanical components. This is then another cost to consider for the project, and obviously work cannot be conducted whilst maintenance occurs.

I am sure there are many more benefits and disadvantages that I haven’t listed here and please feel free to add to it. Has anyone else on various sites past or present used mast climbers? And if so, were the advantages seen over the long term compared to the short-term positives I’m currently seeing? Are there any scaffolding ‘old-guard’ who are vehemently against the use of mast-climbers?