Archive

Talking out of my ASS

So I saw Chris Holtham’s awesome post and decided I should probably put pen to paper (in a digital sense) and bring you up to date with what is happening in the ASS heap that is Hope Street. For those that are seeing my entry for the first time ASS stands for Acid Sulphate Soil or Sulfate as they spell it locally – apologies for the odd bit of colonial lingo slipping in Neil.

The meeting to end all meetings.

We were 25 days behind schedule thanks to the worlds biggest props on site and the decision to weld rather than bolt them together. The safety manager had been fired and the contracts manager had quit from stress. The Project Engineer was no longer speaking to the subbie PM and I was placed in charge of the excavation and ground anchors.

I held a trades risk workshop for the ground anchors and rather than focussing on the risk, my Project Engineer and Site Manager ended up having a spectacular fight with the subbies over the lack of a plan. To sum it up never in the history of construction has the ‘C bomb’ been dropped so much, by so few.

Never forget it is always about people and relationships.

Since then I have fought hard to form a working relationship with the subbies. I have had actively manage the senior management within BM, who take micro-management to Lego Movie proportions (if you have kids or nephews you will understand). The passage of information around the project is appalling and as a consequence I have instigated a regular daily conference with subbies and then briefed the senior management because they can’t be in the same room together.

As the project has gradually come back on track, relations have gradually thawed. I spent today detailing a kind of visual programme/ cartoon method statement for how the job will get down to the foundation level. If all goes well I will have made back the 25 days and will be back on programme. I will handover to the other site engineer, who is not an engineer, but is in charge of the structural part of the construction while I apparently need to do the services – he is the same genius who worked on the struts and walers. How’s that for outside the box thinking?

So What?

Here is the rub. While the last 6 months in Chatham, have given me the confidence and skills to call people out on talking engineering rubbish (and I have). The majority of what I have done in the last two months could be done by any army officer. The ability to talk to people like a normal human being, to state your case in a logical yet firm manner are key transferable skills that the civilian world needs. The civilian world has the perception that soldiers act in a way reminiscent of full metal jacket. I think they could learn a lot from us. Communication is key to any undertaking, taking a robust position does not necessarily mean having a blazing row. Firm, respectful and logical beats idiotic rants any day (although this article may seem like one).

Other stuff that has happened. That I will write about soon.

- The braces of the loading platform buckled (my structural site ‘engineer’ colleagues responsibility) – TMR gold apparently.

- How to build foundations straight onto rock.

Soil out and Props in

We have had a very busy couple of days on Hope St, the big props are now in on the North side and the Acid Suphate Soil (ASS) is being rapidly extracted. We excavated 1368 cubic metres yesterday and over 600 cubic metres the day before. The site is starting to look better and progress is being made. Everyone is getting gradually less stressed.

It looks like the working platform will work and there is enough spare capacity in the props and wailer to cope with the lateral loads from the excavators (but we knew this anyway). I thought the photos might help future students on Exercise Cofferdam. Note the splices in the props, the ramp for outloading dirt and the excavator pairs working in tandem. .

KNOWING YOUR ASS FROM YOUR ELBOW.

In my last blog entry I mentioned Acid Sulphate Soils or ASS. I have been put in charge of the safe disposal of the ASS. Not only does this help me cover the sustainable development piece for CPD but, more importantly allows me the opportunity to talk ASS whenever I want.

A heap of ASS. Note at the time these stairs were the only egress and the black smudges/ooze.

So what are acid sulfate soils? Here comes the Science…

Acid sulfate soil is the common name for soils that contain metal sulfides. In an undisturbed and waterlogged state, these soils may pose no or low risk. However, when disturbed or exposed to oxygen, acid sulfate soils undergo a chemical reaction known as oxidation. Oxidation produces sulfuric acid which has led to these soils being called acid sulfate soils.

How and where are acid sulfate soils formed?

Acid sulfate soils are formed by bacterial activity in waterlogged conditions when there is no or little available oxygen.

Naturally occurring bacteria convert sulfate (dissolved salt) from seawater, groundwater or surface water into sulfide (another type of compound that contains sulfur). This sulfide reacts with metals especially iron in the soil sediments or water column, to produce metal sulfides (the main components of acid sulfate soils). In order to convert the sulfate into sulfide, the bacteria also need a source of energy provided by organic material such as decaying vegetation.

So what I hear you say!

Well we have just dug up a lot of this soil, exposed it to air then added a good downpour of monsoon rain onto it and left it there to get really nice and acidic. Essentially any water we pump out has to be treated like sulfuric acid and needs to be neutralised. So you can imagine my joy when the bloke came to pump it out this morning then proceeded to let it leak out of his truck on the way to the disposal site.

For Damo!

This will be where the lime is added once the water tank has been moved.

The Water holding tank is in the top right hand corner of the picture and needs to be moved to the corner of the excavation to avoid stressing the wall.

Grab your Stetson and Run for your life..

Grab your Stetson and run for your lives!!! – BRISBANE CASINO TOWERS

What the client is selling it as.

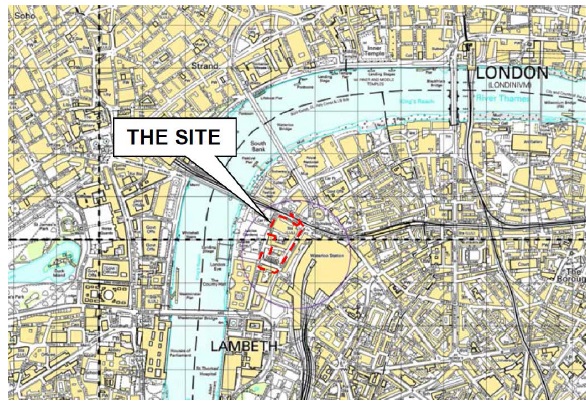

Introduction. So I started work at Brookfield Multiplex on the Casino Towers project on Hope St in South Brisbane. The project is a 30 storey residential tower block with 6 floors of basement. The contract is a fixed price Design and Build contract for Metro Property Development. BM has taken on all of the risk with this contract under a fixed price and a tight deadline. Time and cost are paramount with tough liquidating damages for overrunning, so the pressure is on. Much of what the project team do is manage other sub-contractors and liaise with their contracted designers. Location wise the site is situated in an interesting area between two blocks of high-rise social housing whose occupants are none to happy about our work and have been keen to let us know by throwing their used needles over their balconies and into our site.

The clowns to the left of us

The clowns to the left of us

The jokers to the right

Stuck in the middle in poo or Acid Sulfate Soil (ASS)

Contract out risk. At the moment we are at excavating the basement. The team has little to no experience of excavating basements and have sub-contracted this phase of a contract to Delta on a Design and Build contract. Delta in turn have sub-contracted the propping system to QPS, with Delta taking on the bulk of the mud moving for themeselves. Unfortunately BM sub-contracted the piling work out to Franki Pile and as the supports and wall work as a system are still carrying much of the can. Wailers are clashing with the future floor slabs and given that the site is at a slight angle, it has all got very complicated.

![Q2454-0001[01] (1)](https://pewpetblog.com/wp-content/uploads/2016/03/q2454-000101-1.jpg?w=595)

Prop Layout at first level of supports the remainder is Ground Anchors

Managing Sub-Contractors. While BM has contracted out the basement they seem to have little leverage into motivating the sub-contractors. They have been accused by the subbies of micromanaging but, it is clear that the subbies are not up to the task. The secant pile wall/propping system has not been designed for construction loads and we can’t even unload stores close to it. On the flip side it would seem that with only one engineer on the project up to this point the scale of the task has over matched him and BM have not asked the right questions before they got to this point.

Struggling to fit the whalers in place

Propping system. QPS are the subbies in charge of the propping system and are more used to ground anchor systems and have struggled with installing a workable propping system. This is the biggest job they have done and frankly it shows. My key criticisms are they insist on welding everything on site, as opposed to preparing off-site and connecting with bolts on site. At the last count 9 of the first 10 welds have failed and need to be redone. They have not really thought about how it will go together and many items have arrivied out of tolerance. The project is now about a month behind schedule. I took a ride out to their fabricating facility. There is a huge capability gap from what we saw at Nu-steel and what QPS can produce. The whole prop system should have gone in last week but the wailing system still hasn’t been fitted. The picture below shows Delta struggling to get the end wailer into place.

The journey of the whaler from factory to floor

H&S. So there are so many issues I scarcely know where to begin. My first appointment was at BM headquarters in the Central Business District. The meeting was about enforcing stricter H&S standards on the various sites around Brisbane. The overarching thing was about moral courage (where have I heard that before) and about safety in design. Monday was a scheduled no work-day so I had the opportunity to inspect the site without any of the sub-contractors (or unions) around. The sub-contractors approach was certainly different from anything I has seen in the UK’s. The stairs into the basement had been undermined by the heavy rains and were pretty rickety. I was also struck by the confined nature of the site and the little separation of people and plant.

Our Union Rep checking H&S standards -integrity is not his strong side. You can see the plunged columns that will support the working platform.

Labour disputes. There have been real issues with unions in Queensland. At the start of the week a construction site on the next street had been shut down after a union walkout. By Tuesday, it was our turn with the union rep/commissar proving his wide and diverse vocabulary regarding his concerns about H&S on site. The union used the rickety stairs and the lack of any other alternative exit to shut down the site and to be fair he had a fair point. However, you can see the reps keen interest in PPE as he encourages the Delta employees to ‘knock off’ for the weekend on Friday.My role – Resitting Exercise Cofferdam, working out how I can get an excavator to move the ASS without exceeding the maximum surcharge of 5 KPa within 3m of the wall.

Boundaries, Properties, Groundwater, Contamination…Constructability!

.

.