Archive

A Forgotten Post: Almost a Civil Engineer…?

Task Overview. Part of the Substation Scope of Works was the installation of two 1500 kVA transformers, both weighing 5000 kg.

Expedient Engineering Opportunity. Initially functioning as a supervisor to the wider-Substation construction, it was during a routine meeting that I noticed no detailed plan existed to safely install the transformers. The original idea to lower transformers into the Substation had overlooked that the roof and doors to the structure were installed early. (At the time, the Project Manager thought this was a “quick win”.)

I resolved this issue by devising a plan to design and construct a temporary platform in order to safely install the transformers. Realising my very limited Civil Engineering competency, I engaged with an approved subcontractor – Shore Hire – to develop my concept into a legally recognisable design, should something go wrong; I achieved assurance by requesting a design certification from Shore Hire’s engineers.

Pictures: (Top to Bottom) Initial proposal; detailed design from Subcontractor; design constructed; and, transformer being released from the crane and wheeled into position.

Until next time…

Health & Safety: The Journal Continues…

Here you have it sports fans, more snaps from my Health & Safety Journal!

That’ll do there!

Stored High in Transit (SHIT)

Do I really need to conduct a Confined Working Space Assessment?

Game of Standards

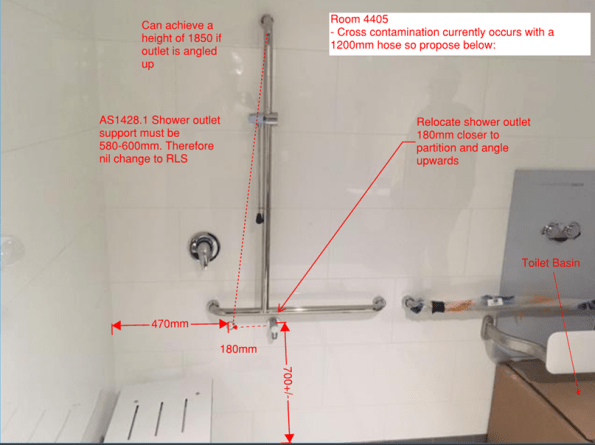

Tasked to investigate a potential cross-contamination issue within a number of disabled en-suite bathrooms, this post aims to articulate some of the issues that I came across.

Task Overview. During a scheduled visit by the Client (New South Wales (NSW) Health Care) of the Acute Services Building (ASB), it was minuted that a shower hose within one of the disabled en-suite bathrooms had the potential to make contact with the toilet basin – a cross-contamination issue. My initial task was to support a Graduate Engineer to investigate this claim.

Response to the Task. My first action was to establish the facts; what Australian Standard (AS) must installed shower hoses comply with? The Standard, AS1428.1-2009 Part 1 (Design for Access and Mobility), stipulates “that the base of the shower rail should be 700 mm above the floor, with a minimum of 1500 mm hose length”; dimensions sufficient enough for a patient to grab the hose or for a carer to wash an individual.

I then discussed the issue with the Subcontractor responsible for its installation. Of interest, and not surprisingly, the Subcontractor’s representative attempted to reassure me “that all was well” with the installations. I was not content with this level ‘assurance’ and conducted a full inspection of all 24 disabled bathrooms; 6 were confirmed as having shower hoses which could make contact with a toilet basin. (The shortest hose length to avoid contamination would have to be 1200 mm, 300 mm below the AS.)

Unable to recommend the use of a smaller hose length at this stage, and to avoid raising an unnecessary variation, I arranged a User Group meeting to establish ownership of the risk and present a solution. My initial recommendation to the Client, confident that AS 1428.1-2009 Part 1 would suffice as justification, was to implement addition disinfection measures into daily working practices to mitigate the risk of any contamination spreading. This was rebuked with another Standard, AS 3500.1:2015 Part 1 (Water Services), by the Client’s representative, which claims that “any cross-contamination potential must be mitigated”.

Mistake made: Not widening my understanding of associated Australian Standards.

The Regain. Unable to resolve the associated risk due to this AS “deadlock”, and with a young graduate stumped for options, I seized the initiative to seek advice from the Building Codes of Australia. Now furnished with an understanding of the Disability Discrimination Act (DDA) 1992, drawing attention to “it is against the law for public places to be inaccessible to people with a disability” (Australian Human Rights Commission, 2017), delineation of AS was achieved by the interpretation of a clause that states “to comply with the DDA existing places may need to be modified to be accessible, except where this would involve unjustifiable hardship”; AS 3500.1:2015 had won the argument.

Acting on this information, I drafted a preliminary design that minimised “unjustifiable hardship” while mitigating the risk of cross-contamination; better to inconvenience the User rather than raise the risk cross-contamination across several areas of a hospital. My recommendation, illustrated below, includes relocating the shower hose rail further away from toilet basin and shortening the hose length below 1200 mm. This recommendation was upheld by MPX and the Client. A variation was then raised and a Site Instruction issued in order to complete the works.

A Quest for Answers. Understanding that one can’t foresee everything, and curious by nature, I then researched if a similar experience occurred elsewhere. It had, and in Australia! An article in the Master Plumber, Western Australia discusses that AS 1428.1-2009 is “continually being debated by installers, designers and compliance officers throughout Australia”. However, it did not provide any substantial root cause solution.

Still intrigued to find the root-cause, further investigation points towards an error by MPX’s architects. In short, they have not designed all of the disabled en-suite bathrooms large enough, despite issuing “For Construction” drawings to the Subcontractors!

Until to next time…

Health & Safety: Australian Style

I’m back!

This being my second post/blog thingy, I thought that I would share with you all my love for Site Safety in the form of some snippets from my Health & Safety Journal – yes, I really do have one! As always with Supervision: It is good to trust, but better to check…

Feel free to exchange your own photos’ with me in the Comments Section. For now, here you have it, my top 5 spots to-date on-site: (In no particular order.)

The Waste Bin

Poor Sign Husbandry

Eye Protection…What is That?

If in doubt, MacGyver it!

And…Yes! This happened.

It goes without staying; I am making lots of friends on-site.

A Yorkshireman in Sydney…

I will start with a confession: Not one for Facebook, Twitter, Instagram, or any other real interaction with Social Media, this is pretty much the first ‘proper’ blog of my life. (Although I suspect most are not interested in that fact and want to read on!)

Down-to-business, and following on from a string of “I do this on site” type blogs, I invite fellow bloggers, backseat readers and academic staff alike to read my submission.

Following in the footsteps’ of James Grant, I have found myself (not literally) employed as a Services Engineer on a hospital redevelopment project nearing its end. The Project is summarised as:

PROJECT

St George Hospital Redevelopment. (Stage 2 of 5.)

CLIENT

New South Wales Government, represented by Health Infrastructure.

MAIN CONTRACTOR

Multiplex, part of Brookfield Asset Management (Portfolio worth $260bn).

LOCATION

16 km directly south of Sydney’s Central Business District. (Think Opera House and the Harbour Bridge area of Sydney.)

DELIVERABLES

An 8-floor Acute Services Building; an extended car park (from 7 to 8 levels); an MRI unit; and, the refurbishment of the hospital’s existing Tower Ward Block.

PROJECT VALUE

$170m, of which $80m is assigned for Services.

CONTRACT TYPE

Known as a “GC 21”. Works are conducted under a Design & Build arrangement and the contract is comparable to that of the NEC 3.

CONTRACT RISK

A “fit-for-purpose” clause leaves much open for debate between Stakeholders. Despite User Group Workshops, differing perceptions of what this clause entails leads to time-consuming meetings and potentially costly outcomes.

RESPONSIBILITIES

According to the Project Management Plan’s description of my role, I am responsible for the management of all aspects of electrical, mechanical, hydraulic, fire, security and lift services design, coordination, and installation, completion, commissioning and training for the project. This includes quality control, negotiation with subcontractors and obtaining approval as well as liaison with the Client, Architect, Consultant, Subcontractors, Construction Team and the User.

REALITY CHECK

Although my job description is quite clear, the initial reality of my responsibility has been different. Understandably stuck somewhere between a Graduate Engineer and Site Engineer in the minds’ of others, I have had to reinforce why I am on site, what I am trying to achieve, and how I should achieve it. Effective communication is proving critical; time is at a premium from those that I am seeking help from.

Beyond the observations listed above, I am intrigued at just how complex applying Design Philosophy in Construction can be. Focusing on St George Hospital as an example, from its inception of an 8-bed ward cottage hospital, constructed in 1894, it now has approximately 550 beds, 2500 staff, serving 250,000 district residents. More than 45,000 admissions and 723,000 outpatients are administered each year. The last iteration to the hospital’s expansion, a previous redevelopment project, was conducted in 1980 costing Aus. $200,000,000, designed to last 50 years. The problem is the fundamentally the same – population modelling. To compound matters, construction constraints on the site are increasing – building more on a live hospital site, with less space, more traffic and, increasing competitiveness for resources. The space available to off-load resources for the entire site is constrained to 825m², approximately 1/7th of a football pitch.

Future proofing designs is a difficult art. In my opinion, it is the resilience to change. To achieve this, one must look beyond life-cycle costing and focus more on whole-life value; a philosophy difficult to sell in business cases which focus on value-for-money for a specific budget year.

Away from trying to understand more about Construction, and despite bags of encouragement from my new work colleagues, who have rather ingeniously given me an Australia nickname – Fisho – I still drink Yorkshire Tea, not oodles of coffee. (Although, if I had my time again, I would open a coffee shop in Sydney. #moneyprinting)

Until next time,

Fisho