Archive

Mobile Nuclear Power

Hey guys,

I found this article on the Wavell Room that I found quite interesting and thought I’d share it with you.

Mobile Nuclear Power Will Enable a Logistics Revolution for the Army

The main idea in the article is that mobile nuclear power is something that would reduce the logistic effort required to power military forces. Meaning less convoys full of fuel that would be vulnerable to attack; and therefore save lives as well as reduce wasted resource. The article also explains that future electrical energy demands of military forces are going to continue to grow; I do believe that to be the case, but is there any reductions that can be made by employing more efficient technology (motive being to decrease the vulnerability of the log chain over environmental sustainability in this case)?

Has anyone got any knowledge or experience of the technology the article is proposing who can comment on the technical reality and the benefits & drawbacks?

Also – I would recommend the Wavell Room to anyone interested in keeping up to date with military thinking; I am aware that at least some of the course are already on it!

How much civil/structural can an E&M manage?

Hey Guys – I hope to use this blog to pose a problem only – generate discussion, and follow up in comments or a blog to let you know what I did about it.

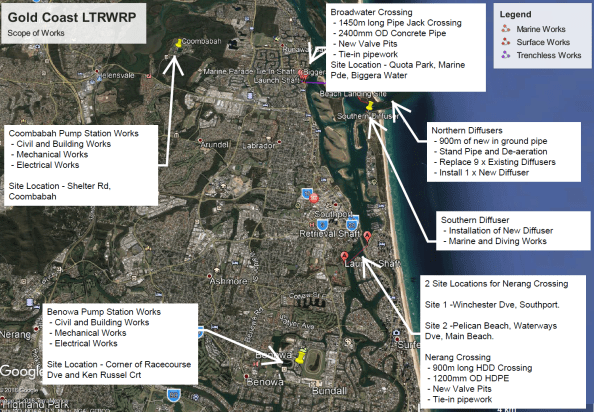

Firstly and briefly – I am attached to the Gold Coast Seaways Project – we are upgrading two pump stations that serve to release recycled water on the Gold Coast out to sea. A map showing project activity can be found below. It consists of two pipelines (northern and southern) and we will have left each of them able to shift future flows of up to 6300 L/s.

Project overview map

And it is in Queensland Australia……

Sorry

Since arriving on site back in April; I have noted that the Engineers on the Project are flat out and separated from one another by geography as well as function. It is almost like 7 separate projects (each headed by an Engineer) rolled in to one headed by the PM. Meaning that interdisciplinary teamwork is difficult at best. I have made good progress in breaking down some of these barriers and managed to get my hands on to some interesting Scopes of Work(SoW), from a range of areas.

However, as a result I have become the go to engineer for that extra little scopes that no-one else wants, some of which I have politely avoided. But I have picked up some pretty interesting little tasks from underwater construction to lifting with no head room. I might pick up on some of those in a later blog; for the time being structural strengthening!

My main task is to deliver mechanical installation at 2 pump stations; I am teamed with an electrical engineer and a mechanical engineer, but no structural engineer. I have some big pumps and motors to move around the place, some of which have been noted by the designer to exceed the load limits of the existing infrastructure and therefore the preliminary work to the main event (the E&M) is a bit of civil and structural.

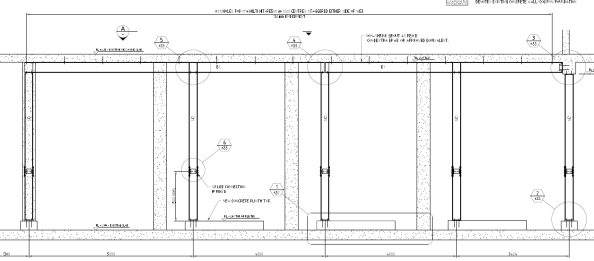

This particular task was to install 5 columns and 2 beams to strengthen the mezzanine floor (drawing below) which will be loaded with the new motors later in the year; no big deal?!?!?

Structural Drawing Snapshot

I was to:

- Read the drawing to put together a scope of works package.

- Submit to potential subcontractors.

- Assess the tenders and award the subcontract.

- Manage the subcontractor through to completion of works.

Problem:

- I don’t know where to start with checking the drawings.

- Any changes I might want to make for practical reasons (clash with my pumps), might not comply with the engineering.

- RFIs raised by the subcontractor will likely push beyond the bounds of PET fundamentals phase.

That said – it’s just management; right? I have done management since joining the Army. This scope is dwarfed by many of the others on the project (magnitude of time and cost) – can I assume that the complexity of engineering is minimal? The designer has already designed it, so I don’t need to do much more than just get someone to fabricate and assemble?

Questions:

- How should I comply with UK SPEC to ‘identify personal limitations, disclose them appropriately and ensure that the implementation of this scope is not hampered by my lack of knowledge’?

- Have you got examples of out of discipline work that you have had to manage?

Finally – it did get installed – and hasn’t fallen down (yet) – so can’t have went too badly.

The Finished Product (anyone spot what’s missing?)