Archive

AR has arrived?

Just a quick follow up from Ali’s blog below regarding the use of Augmented Reality (AR). Looks like 170Gp are already pushing the technology with the ‘powers that be’. A couple of pics from Comd 8X’s recent visit to 63Wks Gp, where he was able to take a tour of Project ANEMOI through AR goggles. AR has been developed during 170Gp’s Innovation and Experimentation trials.

Response to ‘Screw it!’

This blog is a response to Auggy’s post below (Screw It!) as I can’t add images to the comment (apparently there is a plug-in, but I don’t have it).

Auggy, having spoken offline about never seeing these used before, I am now seeing screw piles everywhere!

I am currently working in the design office for a level crossing removal project (Level Crossing Removal Project) which is grade separating the road and rail network at 75 locations across Melbourne. We are just about to start the developed design on two level crossings at Mentone and Cheltenham. In these areas the grade separation is achieved by lowering the rail line into a trench (approx. 9m below current ground level) and then bridging the road crossings. The works package includes retaining structures, multiple bridges, two new stations, three high-rise over rail developments and an urban regeneration project; so lots of scope to get involved in a number of disciplines.

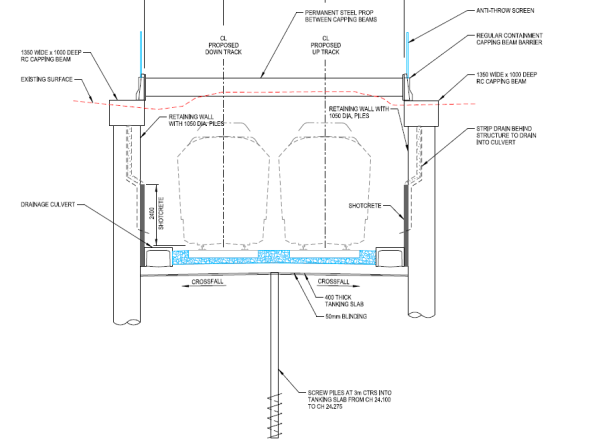

Anyway, screw piles. At certain chainages, the trenching of the rail line will be below the ground water table and therefore a tanking slab is required. From looking at the design drawings (below) it appears that screw piles are being used as tension piles to assist the tanking slab in resisting the uplift forces. As you’ll see from the drawings the tanking slab is only 400mm thick which, without looking at the calculations, seem thin to me. This construction is undertaken close to the beach and the ground in this region is a local formation of sand and clay, so there likely considerations for heave with the design of the tanking slabs, however, I have not yet been able to uncover the geotechnical report to confirm.

In summary, it seems that the application of screw piles is more widely used than I first thought and would interesting to see if these are being used more widely in the UK?

A sign of the times….

A quick blog to share an event that happened this week in Melbourne, which reiterates the risks involved in design and construction. On Monday, I started my Phase 3 placement with the Transport and Infrastructure (TI) section of WSP. On Wednesday, a “bit of a flap” occurred in the office as an overhead road sign and part of the gantry collapsed onto a car (to note, there was no strong wind on that day). These links will take you to the news articles and dash cam footage from other vehicles travelling on the freeway. Luckily the driver of the vehicle suffered only minor physical injuries.

The freeway was re-opened to the public less than 12months ago following a $1.3billion upgrade and widening project. WSP were part of the design team and responsible for some of the gantry designs for Stage 2. CPB delivered the construction. Following the event the Client (Major Road Projects Authority) and the asset manager (VicRoads) initiated an immediate review of the full design documentation, construction documentation and remaining gantries to identify any additional risks (and also blame). Fortunately, for WSP, it turns out that this gantry is not one they designed – which was a relief for many in the office. The investigation is still ongoing, but it is believed the failure was in the gantry connections – either a poor design or not constructed to the design (current thinking is the latter and fault is with CPB QC procedures during construction). I will update the blog in the comments when the report comes out identifying the fault. As I start my first week in design, I thought this was a good reminder of the risks involved even with simple structures.

National Trust vs Apple; Who will win?

This isn’t a technical blog, but a quick update to share experience of a heritage issue we are currently working through in my construction precinct. One of our three station entrances is to be constructed in an area known as Federation Square within the Melbourne Central Business District (images 1 & 2). Construction work was due to start on 2 September 2018, however, we have just been served with a 60day interim heritage protection notice for Federation Square. The protection notice is the result of an application by the National Trust to the Heritage Victoria Register, in response to the Victorian Government approving plans for the construction of the new flagship Apple store at Federation Square (image 3). The development of the Apple store requires the demolition and relocation of the Yarra Building which currently houses an indigenous people museum and arts centre (image 4). Federation Square was developed in 2002 as a central meeting place for Melburnians where the culture and heritage of the City could be displayed and public events could be held. The previous Melbourne City Square was sold for re-development. If Federation Square is granted heritage status then all current and future construction works, including our station entrance, will require to go through a lengthy permit process to ensure that the design can meet the criteria for constructing in a heritage area. The project is unsure which way the decision will go. There is currently no precedent for heritage status being awarded to such a young structure (16 years). However, the Victorian Heritage Act 2006, does not specifically define how old a place must be and the Heritage Victoria Register will consider any nomination put forward. The issuing of the interim protection notice has initiated talks with our Client (Rail Projects Victoria) to identify which clauses of the contract can be triggered now and what are the time and cost implications if the heritage status is granted. I will keep you updated with how this one turns out.

Image 1 – Aerial view of Federation Square. Proposed new station entrance bottom left and proposed Apple store center right.

Image 2 – Proposed new Metro Tunnel Entrance at Federation Square

Image 3 – Proposed new Apple store. View from Yarra River.

Image 4 – Current street view of Federation Square. Buildings on right of picture to be demolished for Apple store construction.

Time spent on resin is rarely wasted..

This blog is mainly aimed at my fellow phase 2 students and will probably appear obvious to the more experienced readers. However, I thought I would share a quick post about the amount of construction time that could be saved by challenging the detailing the design team annotate on drawings.

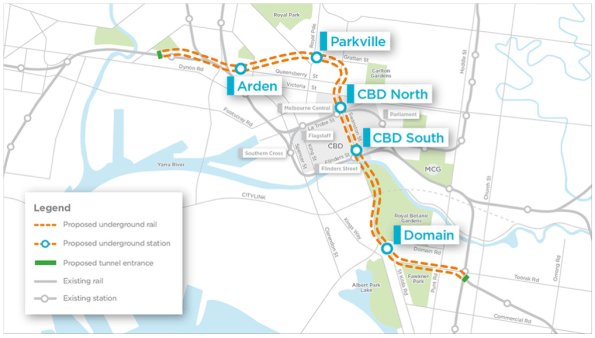

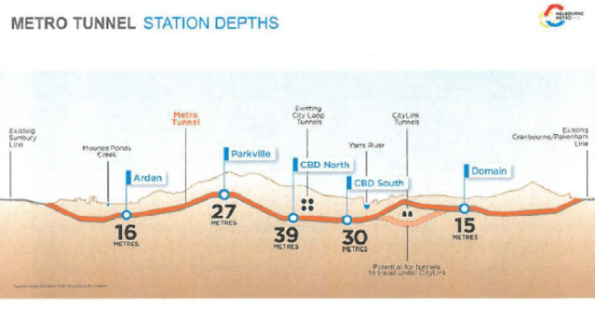

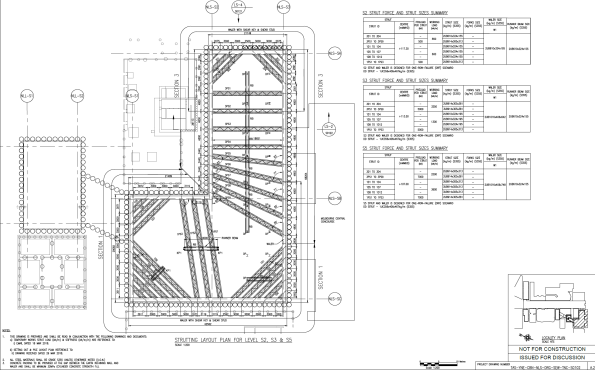

Firstly, as I have not yet blogged about my project, a quick introduction is required. I am working on the metro extension project in Melbourne, which is being undertaken as a joint venture by John Holland, Lendlease and Bouyges Construction under the contractor name Cross Yarra Partnership (CYP). In short, over the next 6 years the project will deliver two twin 9km tunnels and 5 new underground stations, with multiple entrances, within the Central Business District (CBD) and close suburbs (figures 1 and 2). The project is at the very beginning of construction and I am working within the CBD shafts team, delivering the 8 CBD station boxes that will allow access for underground mining operations and form the outer perimeter for the permanent station boxes (for the civils, think a more complex version of EX COFFERDAM). My current responsibilities are aligned to the design, procurement, installation and quality management of the temporary strut support system for each of the 8 CBD excavations, for which, the design and supply sub-contract has been awarded to Yongnam Steel (based in Singapore). Figure 3 shows a typical plan view of the strut layout.

Figure 1 – Metro extension alignment

Figure 1 – Metro extension alignment

Figure 2 – Metro extension station depths

Figure 2 – Metro extension station depths

Figure 3 – Typical strut layout

Figure 3 – Typical strut layout

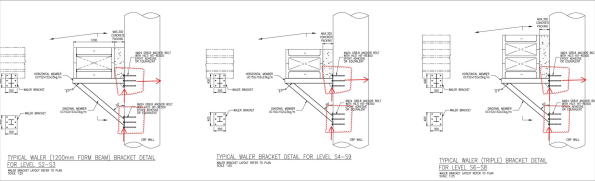

So, into the meat of the issue. I was asked this week to investigate ways in which the installation timeline could be ‘rationalised’ to try and gain some time back on one of the excavations. Feedback given by the team working on site identified that the critical path for the installation of the waler and strut at each level was aligned to the amount of time the resin, for the bolts holding the waler support bracket, took to cure before loading (Min tcure). On the design drawings (figure 4) supplied by Yongnam, the detail stated that the epoxy adhesive should be Hilti HIT-RE500 or equivalent. As detailed on figure 4, this instruction is the same detail for each of the levels of struts, even though the waler and strut size at levels S6-S8 is much larger than the upper levels. The selection of the resin is based on the calculated shear and tension at the bracket location. The installation team suggested that this is most likely a standard detail on the upper levels, basically, to meet design timelines Yongnam will have designed for worst case shear and tension and then applied this across all levels. In terms of time, the minimum curing time for HIT RE-500 is 16hrs, which means the installation process is split across multiple 8 hr construction shifts. Whereas, for lower calculated shears and tensions, HILTI have other products such as HIT-HYH 200-R which cuts the tcure down to 2.5hrs, enabling more construction to take place within the 8hr shift and speeding up the overall installation process. There is also a combination of bolt size and resin selection that can be achieved to optimise tcure for each level of struts, dependent on the calculated shear and tension.

Figure 4 – Waler bracket detail

Figure 4 – Waler bracket detail

The RFI has been sent back to Yongnam to confirm the shear and tension at each plate location, so we can rationalise the selection of the bolt and the resin selection at each strut level. This detailing is something that I had never really considered could have such an impact on a project timeline, especially such a big influence on the critical path. This may be of some use to other phase 2’ers being asked to rationalise their own construction timelines. I will update the blog in the comments when I get the feedback from Yongnam and the final calculation of time saved is completed. Thoughts welcome on any other tips and tricks for cutting this time down?