Archive

Wood Street Police Station

At the risk of sounding like Jessy from the fast show (for those old enough to remember that): This week I have been mostly working on the redevelopment of the Wood Street Police station…

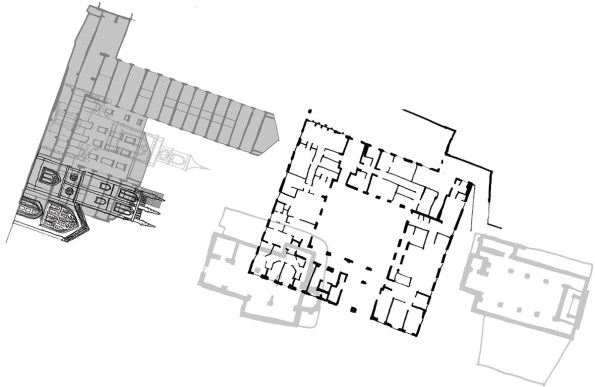

This is the headquarters of the City of London Police (CoLP). A sub-branch of the Met that look after the area around St Pauls and the financial district in the centre of London. The site was built between 1963-66 and sits within a compound containing buildings sat around a central courtyard, all on a two storey basement.

I can’t give you plans or internal pictures of this as I’m not allowed to download them from our secure server. Apparently they think me not trust worthy. What do they think I’m going to do? Upload them to a blog? How dare they?! SO all these photos are open source. And if you really a look inside you can watch this: http://www.bbc.co.uk/iplayer/episode/p01rrjbx/building-sights-series-4-5-wood-street-police-station

The plan is to put a 16 story tower in that courtyard adjacent to the existing tower. There are some problems with this…

Firstly the foundation design. The site is probably sat on London clay. I say probably because the CoLP won’t allow any sort of site investigation until planning has been granted since it would require a hole in the raft slab, and they don’t want one! It might have a couple of meters of gravel, but right now we don’t know. We also don’t know the ground water regime. We can guess it, and the best guess is that as soon as you cut through the raft slab water will come out. So currently the plan is to inject resin into the granular fill in order to drain the water within the working area. Gravel or not it will need piling, which leads to…

Access. The courtyard is entirely enclosed and access is via one of two vehicle “doors”. One leads into the courtyard itself and is both wide enough for a Range Rover type vehicle and tall enough for a dude on a horse. The problem with that door is that the slab that it leads onto will be removed in order to build the new building. So that doesn’t help. Behind door number two is the ramp that leads down into the basement. In order to get down to the second basement level you have to drive through the first level (that slab is coming out too) and down another ramp. You can get a low clearance piling rig, so you could drive one down. But it would be mega tricky. The better option looks like it’ll be to remove the slabs, ramps and all, and crane in the rig. There is the question of how you get the broken out slabs out. It’ll probably involve a skip, a crane and loads of pissed off people trying to get around the truck parked in the road…

There are other problems too. In order to properly assess the existing structures we went into the basement with a rebar meter. The results were a little confusing. Then we found some photos of the construction of the building and it looks like the members are steel, then encased in concrete for fire protection. Some of the transfer beams are about 2 meters deep, so breaking those out will be fun! We couldn’t get any more information as we’re not allowed to do any destructive testing until the budget has been confirmed. The budget can’t be confirmed until the planning pack has been submitted. In order to submit the planning pack we need to know what we’re doing. Which we don’t because we’re not allowed to drill a hole in the floor and find out what’s below it (among other reasons)… It’s the classic circular reference (to use an excel terminology – one for Damo).

All of this makes planning the cost of the project extremely difficult. For whatever reason WYG seem to be the only people running for this job. Maybe because it’s such a nightmare. But the in-house PM and blast analysis combination is definitely a bonus for CoLP since the new building will have to be designed to withstand an attack. That and planning this whole thing is a nightmare!

So while the structures team in Nottingham are wanting to get stuck into some Bentley action, they can’t, because if they do they might not get paid. First we have to work out what can be done, and how…

The illusive c’

Does anyone have any recommendations for a sensible c’ for a soft sandy clayey SILT?

I’m thinking I’ll probably assume something around 5, then bash out a quick sensitivity analysis to see how much difference it makes to my foundation design then make a decision based on risk. But I’d be very happy to hear if anyone has experience in this sort of thing? – Damo I’m looking at you, and John obviously!

Messing about on boats

“Believe me, my young friend, there is nothing – absolutely nothing – half so much worth doing as simply messing about in boats.”

― Kenneth Grahame, The Wind in the Willows

![IMG_0028[1]](https://pewpetblog.com/wp-content/uploads/2016/02/img_00281.jpg?w=301&h=401)

My other day out of the office was prompted by a letter from the Environment Agency to FirstPort property services stating that the concrete defences along the river Thames were damaged and needed repairing.

FirstPort did not know it was their responsibility to look after the defences. It turns out they got the management contract for the development from Berkley homes who built it. This particular detail was in the documentation but no one at FirstPort noticed it. So it was a shock to them when they received the letter in the first place.

The quayside in question is on the site of Brunswick PowerStation (think Battersea cut in half lengthways). The quayside was built in 1948 and therefore designed to the DSIR code. I was chatting to John about this yesterday and the code is so old it even pre-dates him! The code didn’t really take environmental factors into consideration and so the concrete cover to the steel is as low as 35mm. EC2 would say it must be a minimum of 65mm. Additionally these large public projects in the post-war years were a good way of employing soldiers returning home after the war to a weak economy and high unemployment. So soldiers would be given jobs on construction sites, this one included. Their workmanship was a bit dodgy as was the compaction methods of the time meaning the concrete is not as dense as you would expect from modern methods.

The combination of little cover, poor compaction and an aggressive environment has resulted in some fairly substantial corrosion to the steel. Chlorides in the environment penetrate the concrete and the steel corrodes. The corroded steel has a high volume than the original steel and therefore cracks the concrete. Which lets in more water and the corrosion starts again. It’s a vicious cycle.

So we hired a boat and a concrete cover meter and went and had a look.

It is repairable. The problem is that it’s going to be an ongoing maintenance burden which will ultimately be paid for by the residents through their maintenance fees. The bill for this will be over £100k, which split over all the properties in the development is not a huge amount of money, but if they have to do significant repairs each year – which they might – the residents are going to get pretty tired of it pretty quickly.

I’ve got to go to a residents meeting there in a couple of weeks to explain this to them all. Not looking forward to that!

Trusting N values = RISK^100

I’m back!

After some weird issues regarding my account, I can now post blogs again albeit I’ve had to get a new account linked to my work email in order to do so. So when I’m finished at WYG we’ll have to try and set up another account on my personal email so I can continue to see the blog – one for Jim to ponder…

Anyway, about three weeks ago I managed to get out of the office for two days. One day I spent on the Thames on a boat – more on that later. The other day I spent in a field.

I’m designing a couple of crossings over high pressure gas pipelines to provide access for vehicles into a quarry. You may have seen my previous blog where I was tearing my hair out over the vehicle loading. A number of site investigations had been completed previously but had focussed on the agricultural or quarrying value of the site. None had collected any geotechnical properties and I need them to complete the design. So I organised a local Geotechnical engineer to go along and do some boreholes.

I got there to find two blokes (the rig operators) stood by the side of their vehicle, looking at the farm land which is the site, shaking their heads. I said hello and they said “We’re not going on there”. Good start. It was a bit wet, I accept that, but what was he expecting?! The engineer turned up shortly after and we walked the site while we waited for the National Grid bloke to turn up. In order to plant a daffodil within 15 meters of a high pressure gas line you need National Grid to send an engineer to observe. I wanted the bore holes as close to the location of the crossings as possible, obviously. The rig operators didn’t want to go onto the field. Their argument was that it was too wet and the rig would sink. I really doubt it would of, but I was never going to win that one, so we came to a compromise. We selected locations for the boreholes that were on the firmer ground at the edge of the field. This meant that the locations were now more than 15 meters away from the gas pipe and therefore the gas man had driven for 3 hours to get to us only to find he now no longer needed to be there. He checked the locations, gave me a piece of paper saying it was all ok and then left, shortly followed by the Geo engineer who let his rig team get on with it.

![IMG_0034[1]](https://pewpetblog.com/wp-content/uploads/2016/02/img_00341.jpg?w=595)

John previously said that once you see a drilling team do their thing you’ll never trust any of their results ever again. I now agree…

Let’s take N values as an example. The book (CIRIA R 143, among others) says that to get an N value from an SPT you hit the stick with a weight and measure the number of strikes to move the stick 300mm (very simplistically). The report also states that poor operator technique can produce disturbances in the soil below the head that then leads to unreliable results, especially in granular materials, the bigger the particle size the bigger the effect. I’m working in gravel. Oh good then!

![IMG_0048[1]](https://pewpetblog.com/wp-content/uploads/2016/02/img_00481.jpg?w=595)

I watched the crew conduct an SPT at around 4.5 meters’ depth. They drove the collar to about the depth they wanted and lowered a weighted tape down the hole to measure the depth. But they didn’t measure the amount of collar sticking up out of the ground and so don’t know the difference. The point with SPT is that the material is undisturbed. If you don’t know the difference in level between the bottom of the collar and the test level, how can you possibly estimate the amount of material that has fallen from the sides of the hole? And this is a particular problem in large particle rounded non-cohesive soils like gravel.

The operators then introduced the rod into the hole and drove it “for a bit”. Not the stated 150mm seating drive. Additionally, BS 1377 states that the seating drive should be limited to 25 blows. I must admit I wasn’t counting, but I’m not confident it was. They then got a stick with some lines on it, held it against the rod and drew chalk lines on the shaft (cue Brad giggling) where the lines were (at about 75mm intervals). They then drove the rod noting how many blows it had taken to reach each line – or there about. The lines weren’t exactly straight but at this stage that was the least of my concerns. The operator then wrote all this down in his book and made a cup of tea while his mate changed the head over.

The crew also took samples at various depths including both the gravel and the underlying clay, which they did pretty well from what I understand. They put the coarse-grained stuff in bags and for the cohesive soils the sealed it in wax to keep the water in and treated it pretty carefully.

![IMG_0071[1]](https://pewpetblog.com/wp-content/uploads/2016/02/img_00711.jpg?w=595)

So what?

So I’ve got some N values and I’m awaiting the lab test results. Do I weight the reliability of the lab test results against the N values since the method of collection looks dodgy? No. There are loads of other factors that affect the accuracy of the N value including the stiffness and exact diameter of the rod and the angle of drive, but I didn’t measure them. So who am I to judge? The factor of safety applied to the results is there for a reason and as long as I try to triangulate the properties with the lab results and anything else I can find I’ll crack on and use them. I’ve got nothing else so I need to use something!

Go on then John, I’m braced!

Stay tuned for… “Messing about on boats”

![IMG_0069[1] IMG_0069[1]](https://i0.wp.com/pewpetblog.com/wp-content/uploads/2016/02/img_00691.jpg?w=294&h=220&ssl=1)

![IMG_0072[1] IMG_0072[1]](https://i0.wp.com/pewpetblog.com/wp-content/uploads/2016/02/img_00721.jpg?w=293&h=220&ssl=1)