Archive

Washington Aqueduct

Americans do things bigger than most and once again this is true for their military in producing potable water.

Each year the military staff with the Baltimore district of USACE (US Army Corps of Engineers) conduct Officer Professional Development (OPD) days much like we do when in green skin. However, one of the reasons they conduct these days is not only to develop personally but to educate their officers on infrastructure and projects that USACE manage or are currently engaged with. Their portfolio of projects is so huge they conduct most of their professional development (less cultural activities) on sites within their own AOR.

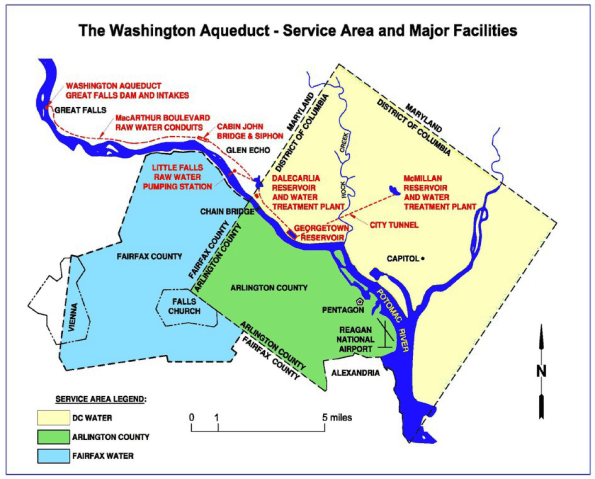

One of these I attended last year was to the Washington Aqueduct just north of D.C. This is a water treatment facility that produces drinking water for approximately one million citizens living, working or visiting in the District of Columbia, Arlington County, Virginia, and other areas in northern Virginia to include portions of Fairfax County (see map below).

I though a blog on this facility would broaden your understanding of the work USACE conduct if ever you work alongside them, highlight the unique water system that supplies Washington and how overall water treatment works if ever we as engineers have to work with such local infrastructure as the British Army did in Iraq or as 521 Specialist Team Royal Engineers did in Afghanistan in producing water from bore holes.

A division of the Baltimore District, U.S. Army Corps of Engineers, the Aqueduct is a federally owned and operated public water supply agency that produces an average of 500 million liters (135 million gallons) of water per day at two treatment plants located in the District of Columbia. All funding for operations, maintenance, and capital improvements comes from revenue generated by selling drinking water to the three jurisdictions. The aqueduct employs 150 USACE employees.

In the 1850s, the growing population of Washington and the memory of two devastating fires (one by the British; huzzah!) forced Congress to acknowledge that the nation’s capital required more than wells and springs to provide its water. In 1853, Congress commissioned a public water system and the US Corps of Engineers designed, built and, in 1859, began operating the Aqueduct.

Water Treatment Process

There are no great surprises for a RE with regards to the treatment. It is a pillow tank operation on a very large scale without worrying about the vehicle route and collection points. Raw (untreated) water contains suspended solids, sediment, bacteria, and microorganisms that must be removed to produce drinking water. These are removed by full conventional treatment, described below:

- Screening – On its way from the river to the Dalecarlia and McMillan treatment plants, raw water passes through a series of screens designed to remove debris such as twigs and leaves.

- Pre-sedimentation – While the water moves slowly through Dalecarlia Reservoir, much of the sand and silt settles to the bottom.

- Coagulation – A coagulant, aluminum sulfate (alum), is added to the water as it flows to sedimentation basins. Coagulants aid in the removal of suspended particles by causing them to consolidate and settle. Alum contains positively charged atoms called ions which attract the negatively charged particles suspended in water causing them to gather into clumps of particles heavy enough to settle.

- Flocculation – The water is gently stirred with large paddles to distribute the coagulant; this causes particles to combine and grow large and heavy enough to settle. This process takes approximately 25 minutes.

- Sedimentation – The water flows into quiet sedimentation basins (picure below) where the flocculated particles settle to the bottom. After about four hours, approximately 85 percent of the suspended material settles. The sedimentation basins can hold 166 million liters.

- Filtration – Water at the top of the basins flows to large gravity filters, where the water flows down through filter media consisting of layers of small pieces of hard coal (anthracite), sand, and gravel placed in the bottom of deep, concrete-walled boxes. Filtered water passes through to a collecting system underneath.

- Disinfection – Chlorine is added with precision equipment to kill pathogenic microscopic life such as bacteria or viruses. Ammonia is then added. The chlorine and ammonia combine to form chloramine compounds. The concentration of chloramines in the water is closely monitored from the time it is added at the treatment plants to points near the furthest reaches of the distribution systems. Disinfection is considered by many to be one of the most important scientific advances of the 20th century.

For the E&Ms. Orthophosphate is added to control corrosion in pipes, service lines, and household plumbing throughout the distribution system. It works by building up a thin film of insoluble material in lead, copper, and iron pipes and fixtures. This thin film acts a barrier to prevent leaching of metals into the water. Calcium hydroxide (lime) is also added to adjust the pH of the water to ensure optimal performance of the orthophosphate.

Due to geography and current infrastructure the aqueduct is the only source of water for D.C. The threat to the site by terrorism is considered and the aqueduct continuously monitors these threats with federal agencies, but the risk to the water supply through poisoning is low.

The blue pump is the one that supplies the White house and other key buildings. There are 6 pumps in total. 4 are required for daily operation so one can be maintained and the other held in reserve.

The biggest annual threat to water distribution is the weather. Temperatures can drop well below freezing, preventing water flow at the intake or even freeze the sedimentation basins; this is simply addressed by breaking up the ice with plant. A concern is that eventually, one winter may be too cold for this rudimentary system of ensuring drinking water and yet there is no plan B!

Historically, river solids removed during the water treatment process were disposed of by returning them to the Potomac River. This is no longer permitted. The Residuals Management Project involved the construction of equipment and facilities to collect water treatment residuals from three locations and convey the residual to a central treatment facility. At the central treatment facility residuals are thickened in gravity thickeners, dewatered by centrifuge, and loaded into trucks for off-site land disposal. This method of disposing to land fill is also becoming unsustainable due to environmental concern as is the cost of trucking the residue around.

Anyone with a sustainable solution to this problem should come forward as the aqueduct will pay a good prize.

Could the Royal Engineers provide drinking water to London? We may baulk at the thought but the question is unfair as the structure of both Corps of Engineers is vastly different. USACE alone is half the size of the British Army not to mention the expertise it contains in specialist roles. Maybe we can’t imagine RE operating a critical facility that supplies London but our RE are expected to provide potable water in wartime to a whole fighting force. Responsibility does not get much greater.

It was written above that the process is not much different than our current military transportable systems and how simple some of their process are in ensuring continuous water supply to the capital of the world’s biggest superpower. As future PE we should perhaps have the confidence that we could operate such infrastructure alongside local contractors.

Keep it simple stupid!

We are always taught to KISS in the Army but rarely do we stick to this mantra. Too often it is seen as ‘lacking effort’ to follow what has been done previously and reinventing the wheel becomes a must to be innovative and demonstrate leadership above your peers! The result is mostly a troop of confused chimps trying to understand the intent of the task never mind how to execute it.

As part of the Construction Quality Management (CQM) that USACE use to ensure quality assurance (QA) they employ the Three Phases of Control; preparatory phase, initial phase and the follow-up. The initial phase occurs at the beginning of the task on site and continues each time new work crews are assigned. The follow-up is performed daily to ensure that control established continues. However, the purpose of this blog is my experience with the preparatory phase.

The preparatory phase is performed prior to beginning any work and will review the plans and specification, co-ordinate prelim works, safety and when quality checks take place. How to meet these standards is in the specification and hence my assumption was that this would be a quick final check of a few important details before work was allowed to proceed.

In a pre-construction meeting attended by several experienced project engineers, the client and contractors I was initially concerned that I may be out of my depth having not been a part of the planning cycle. Chaired by the principal contractor (PC), after a few minutes I wondered if I was in the right meetings. I had suddenly either become extremely competent or Americans were a little stupid; given my record I initially went for the latter.

The meeting was about security fencing and the sub-contract (SC) had been awarded to a company who had already been employed on previous National Security Agency work performing well, on time and safely. There were the obvious discussions that I expected about de-confliction with other contractors and site access but then the meeting got ‘simple’.

The PC began interrogating the SC about the fencing and how the corners would be placed, how the connectors would be attached, the testing process and ensuing material was tidy on site. These question would all have been confirmed via the submittals process which itself is monitored by a robust if not longwinded system and therefore already been approved by all parties. Why was the PC questioning such an expert who had already proved themselves previously? At times I thought I could have replaced the SC with Churchill the nodding dog to answer “oh yes” to all the questions. The PC wasn’t asking bigger picture questions; they were questioning the very basic operations of the SC. At what point would the workers put their safety glasses on? Will they use two people when unrolling the fencing to make sure it does not spring back into a roll? The contractor was having to explain a verbal method statement of parts of the work the PC should never need to know. It was akin to a CO confirming where the section commander was going to keep his G1098 tools when on task and if everyone had put 30 rounds in each magazine. I was almost uncomfortable; here was a contractor who has erected fencing at one of Americas highest security bases and the PC was confirming if they were going to wear the correct gloves to handle the razor wire!

How many man-hours was this meeting taking? Are we honestly confirming that the contractor will store the material more than 4 inches off the ground overnight and keep the site tidy! At each stage, stakeholders were jumping in with the simplest of questions to ensure they too got an “oh yes” from contractor Churchill.

But this is the process. USACE insist on it as part of accepting a tender and are rigid with QA business. They have little sympathy for work that is not to the correct specification; it is simply ripped out. Hence the importance for the PC and contractor to get it right the first time: any re-show is at the expense of the PC.

By keeping it simple so that everyone understands and taking the time to “measure twice, cut once” can save days of rework later. The system works if those involved embrace it. The saying “if it’s not efficient, change it” does not exist; there are no promotions for shortening the meeting or changing the process so why reinvent the wheel. Yes, the meeting takes time and is potentially inefficient but the time cost to the PC and USACE is far greater if the sub-contractor delivers a product below quality or compromises safety.

If I had chaired this meeting I would have felt that I was insulting the contractor or at best wasting their time and have felt it necessary to add another dynamic to the meeting to make it worthy of everyone’s time. This would result in ignoring the simple basics and adding confusion to a process they know and find simple, potentially setting the task up for failure. They would then rightly tell me to KISS.