Archive

Its been a while, but things are ticking along fine in the design office

Hmmmmm, been a while since I’ve written one of these, anyone would think that a thesis, several reports, a day job and moose-dodging in the Alaskan wilderness might use up one’s blog-writing time…..!

For the serious stuff (if like me you read the funny stuff first, scroll down to the bottom):

I’ve now been working the Mechanical section of the USACE design office for a couple of months, and am enjoying the work greatly, the 3 hours each day wasted in the Baltimore commute not so much, thankfully though no car accidents yet.

The largest single piece of work I’ve been working on has been progressing the design of a renovation of some military accommodation in Boston. As handed to me, this was at a very early stage of development and so I have been able to take responsibility for the advancement of the mechanical design. This has been considerably slower than I would have liked due to the necessity of learning several of USACE’s software programs that I am unfamiliar with (I long for HEVAComp!) It does seem that every individual step requires a new piece of software, so whilst I am broadening my horizons dramatically, I am getting a little frustrated with it all.

I am currently evaluating which technology to employ for the updated HVAC system, thus exploring many HVAC options, ruling out the truly ludicrous, and conducting an annual energy analysis of the most likely. The most feasible few, I have explored in more detail; 2-Pipe, 4-Pipe and Water Source Heat Pump in order to cost the initial retro-fit installation. I produced a whole-of-life costing for each option and this is leading me towards the WSHP. The next stage of this will be a more detailed design of the WSHP, although this depends on future funding approval (see below – sequestration). One other frustration is that I have had to work entirely from poor quality pdf As-Builts, given that the opportunity for a recce (jolly) to Boston is not on the cards. It certainly hammers home the importance of good quality As-Builts.

Other responsibilities within the section include inspection of completed drawings for adherence to fire regulations, which gets considerably easier once you understand the basics of US regulations and can anticipate common problems. It was slightly embarrassing to have to point out an error made by one of my mentoring co-workers in a drawing already released to the contractors, which seems to have now highlighted a serious and complex problem that I am now required to help him fix (whoop!). The problem was that he had implemented a system that would easily end up using the main through corridor as a duct, never a good idea! Clearly this is difficult to solve, but much better to have caught it early.

Problems at the SSP continue to roll on.

I am still maintaining a link with the construction work happening at the SSP and USAMRIID. The USAMRIID is moving into the fully fledged commissioning of all the diverse systems, and also getting closer to the point where the contractor ceases to be able to argue that his schedule is true to life. The communication within the SSP project appears good on the surface yet very little work is actually happening and almost inevitably it will move to litigation in due course. I am hoping to be able to observe this.

One of the problems that may critically affect the entire future use of the SSP is the poor concrete quality in the basement, which leaks ground water, not ideal for a bio-containment facility….. If this cannot be solved it may force extensive rework.

New projects on the burner.

I have a couple of new projects on the go, both of which are basically writing specification documents. One is for the plumbing of the renovation of a military building, and yep, you guessed it, it requires me to learn yet another piece of software (and liaise with the IT department for installation, which in itself is a mighty challenge!). The other is editing an Request For Proposal (RFP) for the fire suppression systems of some US Airforce installations in Abu Dabai. This is an interesting insight into the requirements of the fire suppression system and the USACE standardisation (or lack of) of specification documents.

Sequestration concerns.

I’m sure the media has adequately relayed that the US Government’s inner workings are about as cooperative as a box of coathangers, so they have rolled from one near financial miss to another, and the current solution appears to be implementing a four day week for Government workers. This is yet to be finalised within USACE as many people are employed as part of the project funding and thus making the situation more complicated. The lack of clarity is generating lots of rumour control, with people trying to work out what they will do with an extra day off a week (and 20% pay cut). This may affect project budgets but no one is sure yet.

In other news.

Close but no venison steaks for the Hancock family after a hunting season where something called a thesis was getting in the way of a good hunt! I’ve heard that there is to be a deer cull in the UK, hopefully I can help!!

We had a brilliant delayed honeymoon to Alaska, where oddly enough it was quite cold! We stayed in a wilderness hut at -30C on Valentines Day – I really know how to treat a wife on a special occasion….. We did see the Northern Lights, learnt how to husky sled and snow shoed up a mountain until we almost caused an avalanche (we snow shoed down pretty quick!)

I also managed to convince a co-worker to go on sabbatical last month – which management was pleased about, not because she was bad at her job but rather that she had been planning to quit outright, this way they get to hang on to her for a while.

Sarah is looking forward to quitting her job – having recently had to fire a temp for sleeping on the job, mainly bad because he was the site nailgun operator and was standing up with his finger on the trigger.

I hope that everyone is getting on well with their theseseses, it seems very close to hand in date and to us all getting back to the UK. Aaaaaaaah, proper Cadbury’s………

Now arrived in the Design Office in Baltimore

New Office – 10 South Howard Street, Baltimore

I have now wrapped up and handed over most of the work which I was involved with at USAMRIID and SSP sites over in Frederick, and am now daily commuting up the road to Baltimore to the District HQ, based out of the Mechanical Section.

Apart from the fact that the HVAC is broken (ironic, I thought) which makes the office about 30C everything else seems to be falling into place. I am about to go to their weekly meeting which details the existing and expected projects, hopefully will be able to position myself on a interesting yet modular project.

SSP

Back in Frederick, the SSP project is still treading water, though a new Bio-Challenge test has been conducted, which we are currently waiting…… It is expected that a test pass will alleviate many of the commissioning issues, though it is becoming increasingly evident that the “customer” does not want to be responsible for the plant, and so is “stalling” as much as they can, this is clearly making the commissioning, closeout and handover of the plant difficult. As a point in case, last week I had to reassure some of the USAMRIID customers that it was perfectly normal for clouds of steam to be coming out of the steam vent on the steam plant, and did not indicate that the steam condensate traps were broken, and so we did not need to launch an investigation and fix it.

USAMRIID

Construction is still continuing at pace. Several issues have come up, but are being resolved as quickly as possible. (1. Slightly flammable pipe insulation in plenum areas, 2. duct cleaning – cutting holes in ducts that are already tested, in order to clean them…, 3. continuing issue of accuracy of duct testing paperwork, thus throwing doubt about the results, 4. In ability to pull some of the coils out of AHU’s etc)

The main concern as far as I can see is that there STILL really does not seem to be a schedule. Despite this being the case for the entire time that I have been there, and various of us voicing our concerns about this situation, the Resident Engineer does not want to delay the project by calling for a stop work order, (realistically the only stick that would have effect) due to lack of adherence to the specification, so the situation rumbles on. Clearly this will become a more pressing issue when commissioning comes, also, from our inspection of what schedule there is, no time has been allowed for reviewing the submitted system tests etc, feasibly this may cause real embarrassment in about a years’ time, luckily (for him) the resident Engineer has said he will probably retire in 10 months time…

I am intending to continue to pop back to the USAMRIID on a frequent basis, to keep an ear to the ground to hear the outcome of these issues, and contribute to the lessons learnt.

Home Front

Sarah is doing well in her job, and getting used to the fact that she is firing about a person a day, but this is apparently expected when largely working with Ex-Cons.

My Beer is going well, I now have particularly smooth pumpkin ale, (the Americans have figured out a way to make almost anything from pumpkin – ale, pie, soup, stew )

We have now got a Christmas tree wedged into our little place, it is about 9 ft tall and 5 ft diameter, which actually may be a little too big, it does make it feel very forested in our front room, in a nice way. Needless to say, it looked smaller in the field.

It’s been a quick summer

A really quick summer!

It seems that every day which passes picks up speed, and I can’t believe that we are already in mid September.

My time is still split between the two major projects here of the Steam Sterilisation plant and the USAMRIID replacement project.

I am now mostly involves in the commissioning process of the USAMRIID. In the building about 60% of the space is mechanical “room” jam-packed with HEPA filters, air handling units, control systems, compressors, pumps and everything else you could possibly think of.

I am managing the commissioning contractors issue log, this involves answering any questions they have on any of the many systems, in order to allow them to write the system tests that will accurately test and check the equipment, and put it through its paces. Some of these questions then highlight further problems which had not been previously considered, and thus I find myself researching a variety of systems and also going back to the original designer, (who will still have on contract) with a set of further developed questions, this is then resulting in some changes to the specification.

I have become the USACE lead on the in-the-field testing of some of the systems, ensuing that the quality of workmanship is up to the extremely high standard required. As part of this I have found that one set of tests being conducted may have been recurrently inaccurate for a couple of years, which is clearly a concern, as retesting would be extremely expensive and in many areas near impossible. I am attempting to determine the exact level of fault and from there find a quick/easy solution, and subsequently implement a system which will not allow the similar problems to recur.

In the Steam Sterilization Plant things are still fairly static. The higher management within USACE and the Lead Contractor are conducting a very slow negotiation over the final change, as they have been for the past 3 months. The Contractors bid is slowly falling from $2m to $1.6m but still not close to the expected $300K.

There are also systems tests of the SSP which remain failed/incomplete, and also pivotal for the plant to be finally commissioned by the Centre for Disease Control. Again due to the impasse and a hard stop on any further funding from us, getting remedial work and a retest is not currently possible, thus in order to progress we are having to conduct in depth research to determine if the previous test failure can be explained in a way that will not cause a huge rework. I have been in discussion with various laboratories in the US to compare their testing procedures with ours, to ensure we were not including an overly large safety margin. If the SSP continues to sit in deadlock for many more months then it will begin to impact the critical path of the USAMRIID project, and thus huge pressure will mount.

On the home front

Sarah has been working in a HR recruitment company for the past 6 weeks, and is now getting over her horror at the employment laws out here (until recently an employer was well within their rights to ask for your Facebook username and password, and you could be fired for not providing them). She seems to spend most of her day interviewing Ex-Cons who need work, so an eye-opener all round.

My beer is going well; I have now brewed a Belgian Ale, Weisbeer, IPA, Dupple and Pilsner all of which are actually pretty good! (Much to Sarah’s surprise)

We went on a road trip from here to Niagara Falls, the Great Lakes, Michigan and Pittsburgh. About 3000 miles in total: America is in fact quite big!

Blog 24 July

Blog 24 July

1. Intro

Apologies to all my avid fans for not blogging for a while, things have been getting pretty busy and thus interesting for me on site. I will try and keep this succinct, but also cover all the detail that will give you an idea of the site. I apologize for the length of this blog!

2. SSP Progress

The SSP is starting to move out of limbo, though we have yet to agree to the contractors proposal to the change order we sent (seeing as his quote was 4 times higher than our estimate). The commissioning agent has received their back-pay and so is now willing to come back to site, and continue the final stages.

2a. “Matched Flow” discussion.

I called a meeting to discuss the current issues with matching the 2 flows through the heat exchanger. This is heat exchanger is designed to transfer from one tank to another, whilst emptying and filling the tanks. As such having matched flow is essential to prevent either having to spend more time heating the filling tank or having to use copious fresh water to cool the discharge before it hits the sewer. This had been highlighted previously in the commissioning process and a change order agreed to correct it, however we have found that it is still not working as well as we would expect.

It is basically a controls problem, similar to the ones we discussed with Steve and the main problem is the speed with which it can reach its set point. This time was not originally specified, and so currently takes around 10 minutes to reach full flow. This is slowing the rest of the process to an unacceptable degree. It looks like we may have to issue an additional change order stating the time it should reach set-point in (ie full controlled flow)

The learning point: is that specification must truly reflect your expectations, especially on innovative plant equipment.

2b. Failed Cook test.

One of the cook tanks that is used to pressure cook the effluent appears to have failed its “Bio-Challenge” test. This is intended to simulate using the cooker to sterilize 8000 US Gal of effluent. It is conducted with temperature probes to monitor the temperature that the tank maintains, and also a set of small glass vials each of which has a biological sample which must be sterilized. The temperature did not stay above 250F for the full hour and the sample still had live spores. This is hopefully some form of failure in the testing rather than an equipment failure. More information will be coming soon which will allow me to analyze it properly.

Learning point: that commissioning and testing is best handled by a third party with no previous attachment to the contractor.

2c. Proposal from SSP

Having sent a Request for Proposal (RFP) from the contractor they have returned a quote 4 times higher than expected ($2M rather than $500K and 264 days rather than 60). I have been “getting into the weeds” of this proposal and found many laughable mistakes (or they may be attempted extension of reality, such as 25 hour working days). As I had stated in previous Blogs the contractor is way behind schedule and appears to be acting fairly irrationally, and trying to recoup some costs by blaming everything on the USACE as well as trying to charge huge fees for the slightest effort. They have also just replaced their onsite project manager, again a strange move when so close to completion, so we will have to educate the new project manager about the details of the project.

Learning point: that all submissions from a contractor must be fully scrutinized, as dependant on how honest they are they may try all manner of tricks.

2d. Schedule adjustments

We have also been looking into the schedule adjustments made to the SSP by the contractor. Again there are many errors which are either extreme lack of intelligence, or lack of honesty. An example would be that all work on site had to stop whilst they waited for a change order from USACE, and thus we have delayed them. Clearly in reality only certain elements (which in this instance are not on the critical path) had to be stopped. Scheduling tricks like this are littered all over, and so they have created a story which paints them as blame free.

Same learning point as above.

3. USAMRIID progress

3a. Temporary Cooling.

The application of the bio-containment coatings (paint) is on the critical path for construction. The paint has quite tight limits of temperature and humidity in which it can be applied. Currently the weather is hot and damp and so preventing the application of the paints in some areas. MTJV (lead contractor) has rights to use the permanent systems for temporary cooling. They are attempting to turn the system on before it is truly ready, and this is of concern as they are likely to do some damage. The insulation on the chilled water line is not yet vapor tight and so will condense water, remain damp then become mouldy. We have been directed not to tell them to stop, as they will then expect reimbursement for the delay, as it is difficult to prove their system is not ready, so instead I am closely monitoring to point out damage early and so prevent further damage.

Leaning point: easily measurable criteria are required at any decision point or control point (such as turning on the system or not). Contractors will negotiate and haggle over anything!

3b. Electrical Problem (tripping early)

The Central Utility Plant (CUP) provides all the electricity, steam and chilled water to all facilities on the camp. We recently had a problem with tripping the HV feeders. This resulted in a brief game of defensive finger pointing, with everyone checking their equipment and calculations whilst stating they were sure it was another person’s fault. It was eventually solved by the CUP raising their settings, though they were initially adamant that their settings were correct. I have been trying to get all the relevant data, for academic study, but each of the organizations are unwilling to share their data.

Learning point: Basic engineering is often clouded by politics, this slows progress.

3c. Commissioning Progress: Merrick Issue log

I have been leading the Corps management of the Merrick Issue log. Merrick is the commissioning agent for the construction and so they find many and varied problems. In order to generate the answers whilst keeping costs down, I am attempting to answer each question within our office before elevating it to the Architects and Engineers

3d. Differential Pressure sensor.

Due to the high containment nature of the building, each area has its air pressure controlled very accurately. I am solving some of the problems that have been found whilst installing this system, namely that the sensors may become “Pegged Out” during an equipment failure event, leading to a possible containment failure. Clearly this is unacceptable, it may require a $500K change order, I am investigating all methods to keep this cost down.

Learning point: All possible failure Conditions must be designed in, this will save money over the course of the project.

3e. Duct lining in 6th Floor.

In one of the mechanical areas there is insufficient space between the air handling unit and the duct directly above it to fit insulation. The insulation is required to prevent the duct condensing water during the hot moist weather that is common here. We are exploring solutions; the most likely appears to be adhesive duct liner that will insulate the inside of the duct. The customer and designer are reluctant due to the poor track record of duct liner for decaying and becoming flaky and brittle. We are having to explore all other methods, and also reassure the customer.

Learning point: information and expectation management is important to prevent the customer becoming concerned. Technology can move forwards but certain bad reputations will stay attached to the concept, in this case the new duct liner is proven to be adequate, but it is still a duct liner and thus considered a poor solution. This original problem could have been avoided by a 3D drawing and modeling package.

3f. Wall and Riser close ins

I have become the USACE plumbing lead for most of the ceiling and wall close ins.

3g. Plenum Walls inspection problems with QC

The air intake plenums for AHU’s have prefabricated sheet aluminum insulated walls. These have been allowed to corrode whilst in storage or transit, leaving a white substance on the surface. The quality control of the sub contractor and lead contractor both seem to have failed to stop this, so it has fallen on me and one of the other young engineers to perform some really low level QC.

3h. Pipe, pressure line and Duct tests

I continue to conduct pressure and flow tests on the various systems that are being installed, this includes Compressed air, Compressed Nitrogen, CO2, Water systems, Air ducts (both standard and bio-containment) and Air Handling Units

4. Other News

4a. Storms

We continue to have really good storms out here, almost tropical, with continuous lighting, we in fact got evacuated off site last Wednesday due to a storm warning, the office got hit by lightening, though no real damage done.

4b. Sarah’s Job

Sarah has managed to get a job lined up, so that’s a real relief for her as it has been a while. She is working for Randstad Recruitment, in an office that is ¼ mile from our house so very convenient. She is not that impressed with their working practices!

4c. Sarah’s playing in Carousel

Sarah has been involved in the local Frederick Towne Players, who are currently putting on a performance of Carousel. They are generally surprisingly good for a small town community theatre, but still have a few characters in the crew which make it funny!

4d. Bacon Sundae

As part of my cultural learning I am partaking in some of the local delicacies, most recently a Bacon Sundae. This is a Burger King Special, combining bacon and an ice cream sundae. It is as you would expect…

4e. July 4th Celebration

We had a great day off celebrating the American independence, being asked by Americans if it is a day of mourning back in the UK. They really go for it in a big way with the whole town in the Park for sunset fireworks.

First couple of weeks of June

Topics I have worked on

Controls systems – SSP user interface review, and RIID sensor location etc

In the past couple of weeks I have become much more involved with the control system on the two projects. Within the SSP this has involved reviewing the User Interface that has been produced by the controls subcontractor and comparing this with what is required and what is asked for in the specification. Of course all 3 of these are different, and so I had to try and come to a solution which will please the customer and not cost any more, (i.e. not vary far from the specification, and generally trade one step out to two steps back). It did bring it home quite how similar all control systems are; I could really see the value of the controls module we did, although I really wouldn’t want to write the ladder logic for this system. The crux of the situation is that the information is in the system, but the user interface is not displaying as required.

Within the RIID project I have been working with the contractor, subbies and Architects/Engineers to ensure the correct sensors are collecting the correct information from the correct locations. The shop drawings (which were previously accepted by the Corp, but also have the caveat that if we made a mistake it’s not our problem) vary from the design schematics at some points. The data that will be lost due to the differences has to be either classified as irrelevant anyway (something the designer is unwilling to do, in case they realise why it was important later on), or we need to extrapolate it out from other data or the suchlike.

In order to get the cycle of “construction > problem > question > answer” moving more quickly I convened a few different meetings with the various parties. I found that the Architects/Engineers, whilst being very intelligent and very quick on the uptake, find every question interesting and meriting further research, and so I had to keeping pushing hard to get back towards a triage mentality, as we had over 50 different issues to address. These worked well, as we managed to return 20 in 2 days, and assign 25 to further research, and pass the rest to more relevant POCs.

SSP – Squirty bottle inspection of sealant – keep it simple

Things are now very quiet in the smaller project of the SSP, as we are so close to completion, but also having to wait until the design variation has been approved and checked. We have occasional inspections, such as the inspection of the contractors-suggested-variation for sealing the pipe insulation ends, a good example of keeping things simple. The food coloured water was able to be wiped off – test pass!

CI’s Visit

As far as we are aware the CI’s visit went well. It has thrown up some interesting discussion for me and Matt to research, namely the possibility of doing some of the courses run by USACE for their engineers, as part of an induction to USACE process.

Of interest

Lines drawn in the sand, union interaction and quality of work.

There is some trouble continuing to rumble on site as the pipe fitters union is upset that the sheet metal workers are “encroaching” on their turf. This has happened due to the fact that the exhaust air from the high containment labs is piped rather than ducted, to give the highest level of containment possible. The sheet metal workers are responsible for all the air systems, and so have been fitting pipes where relevant. Clearly the pipe fitters union is upset that the work has not gone to them. At the moment the situation is stable, but it is an interesting study into the dynamics of unions. The quality of the work seems to be adequate in the most part.

Prices will always edge up – Corp holds onto small credit for negotiation, contractor places all costs in.

A couple of the problems that I have solved should have resulted in a small (few thousand dollars) credit, however due to the cost of chasing these credits no gain would be felt, so they are recorded for future haggling. When the contractor is given a variation they charge for everything they can, and as a result the cost of the project will always edge up, and of course the variations are excluded from the gain share pain share calculations.

And on the lighter side

Phosphorus in the sewage plant

We have been having problems recently with the local sewage plant accusing us of killing their “good bacteria” with too much phosphorus in the sewage. They have pointed the finger at our Fort Detrick by following the trail back to the camp gate, and then by deduction it was assumed to be the massive building site in the middle of camp. There was a lot of accusatory finger pointing as to who had been illegally dumping into the drains, until I pointed out that the storm water would likely have a lot of fertilizer in it. The Americans hadn’t thought of this as almost all of their systems keep storm water entirely separate from black water. On inspection there are some antiquated systems on camp that still have cross connections, so this seems to have explained the problem, and shifted the blame away from us. No idea how they are going to solve the phosphorus though… (Not my problem…)

Queens’s diamond jubilee party

Sarah and I hosted a Party to Celebrate the Queens Diamond Jubilee (which oddly enough isn’t a public holiday in America), and invited a good portion of the office round to our place. We had managed to buy-up pretty much every Union Jack Flag from across the states, and had them up everywhere in our house. I’m still not sure whether the guys though this was normal, or whether they were being polite by not laughing at the Red/White/Blue house. It went off well serving all the English traditions like cream teas, Pimms and slightly burnt BBQ.

My home brew

The first batch of home brew is almost ready… and I have already tried it: seems pretty good, but also quite heavy – not really a session beer (as I believe it is described).

SSP project will simply not die…

Current situation with Steam Sterilisation Plant.

We have now gotten to a bit of a Mexican standoff with the SSP.

Pretty much all the work on site has been finished, however due to the modification that will have to be made to the design, to correct the problems encountered during testing, we cannot hand the plant over.

Due to the fact that the plant is a large and complex steam system it cannot simply be “turned off and locked up” until the design of the modification has been completed and is ready to be implemented, as the various seals and gaskets will fail on restart.

Grimberg, the lead contractor are clearly in the best place to maintain the system on tick-over as they are fully aware of its quirks, and also it keeps all responsibility with them should there be anything wrong. They have been asked to provide a per diem quote for the caretaking of the plant for a couple of months, and they are clearly aware of the strong position that they are in.

The quote that Grimberg offered and their lack of negotiation flexibility has offended the senior management so much that they have been told to P@SS OFF, and get all their staff/trailers off site. This clearly makes the situation more tense, and a lot more difficult to get the last few bits of work out of Grimberg (namely O&M manuals, which Grimberg seems to be hoping will go away and compost under a desk somewhere, it is requiring quite a lot of very specific feedback, but I am still managing to maintain an amicable relationship with Grimberg’s PM).

In the end I expect that some agreement will be found as it makes no sense to “spoil the ship for a hapeth of tar, ” and also the people that we will almost certainly get to do the work of the modification will be Grimberg, so we do need to keep some working relationships with them.

This is an interesting study into the final throws of the lifecycle of a project, and really indicates the importance of a sound tendering process which fully evaluates all project possibilities, and gets quotes for these as well as the expected work. However no matter how much foresight is applied there will be the unforeseeable and clients/budget holders must have their expectations managed, especially on such a complicated/experimental job.

Other things that I have been working on:

Liquid Nitrogen Cryovent system. USAMRIID

We have managed to get to a solution that is acceptable to all sides with the question of the industry standards of a Cryovent system. We will be using pre-insulated copper piping, the exact placement of the vents will be made by the Cryo Associates and shown on shop drawings. We are acknowledging that this is a change, and paying for the upgrade for copper to pre-insulated copper, realistically this won’t amount to much as the installation cost will be similar ball park. This solution was rushed to due to the necessity of allowing the work to move forward, and these areas be closed in.

Close-in inspections USAMRIID.

We have conducted various close-in inspections, at which we have found things ranging from the stud being cut through to allow a pipe to be placed, to holes in the firewall, to pipes not being fixed for more than 5m of run, and so swinging like pendulum. It does appear that MTJV try at every turn to use the USACE as their quality control, and just see what gets through.

Backward placed heat exchanger USAMRIID.

One of the heat exchangers in the USAMRIID was placed fully back-to-front, apparently “because it was easier to get it in that way, and it doesn’t make any difference anyway.” Whilst it is true that it makes no real difference it has been noticed and mentioned higher up to the client and so now needs has to be corrected for a political rather than engineering viewpoint, no skin off our nose, but the subcontractor is hurting.

On site tests : Pressure Tests of air handling units, Ducting and compressed gas systems.

Every system that is being installed has to be pressure tested to ensure they meet the rigorous standards required for bio-containment, this is really quite a significant undertaking on its own. The process involves a centrifugal pump with a baffle plate that can change the airflow. The airflow in measured accurately by the use of a calibrated orifice plate, and the pressure achieved in the duct is measured by a U tube Manometer. It all looks pretty Heath-Robinson but it works effectively. Dependant on the length (and thus area) of duct being tested an allowable flow rate is calculated.

Pall Filters meetings.

The discussion with PALL filters is still rumbling on, as it appears that testing/maintenance of the filter skids without the use of Isopropyl alcohol will be difficult, however the client is reticent at allowing IPA use due to the fire risk etc. We have coordinated various meetings between the client and PALL to see if a solution to the problem can be found.

Off site tests: HEPA filter skid – Factory acceptance testing.

There are various tests of the equipment before it is installed onsite. This is a HEPA filter skid that is due to be used in many areas of the USAMRIID building. Due to the knowledge gained previously working with PALL filters on slightly similar skids in the SSP we visited the local factory where they make the stainless steel components and assemble the skid. Impressively they had mounted the pressure gauges the wrong way round, and we could see other more significant design problems which would make the maintenance difficult. It is great to be able to catch these early, and so keep the project as a whole running more smoothly.

Officer Professional development day

Attending an Officer Professional Development day was a good opportunity to meet the other uniformed officers who operate within the district. It did hammer home what a civilian organisation the Corp of Engineers really is, and how few uniformed personnel they actually have.

Also of interest

Memorial Day.

Memorial Day is the equivalent to Remembrance Day, however the Americans really go all out for it. It is a national holiday and pretty much each town has a parade of some sort. We went into Washington DC to watch their parade. It went on for a continuous 2 hours mostly made up of high school marching bands, and only at the very end actual military guys. There were thousands of people out in support along both sides of the main street in Washington DC for a stretch of 2 miles. Also Buzz Aldrin was there on a float. It was an amazing show.

Muscle Car Weekend

Matt, Ulli, Rob, Robin, (his Girlfriend), Sarah and I all attended a Muscle Car weekend at Ocean City; a collection of hundreds of absolutely amazing cars, with more BHP than weight in KGS. They really shift, and they were doing unofficial burnouts in the high street, fine in the early evening but it does begin to get a little tiresome at 0300. It also really showed how much time and money people were willing to spend on their hobbies out here, the cars were literally shined to within an inch of their lives, and some were up for sale, showing price tags around the $50000 – $100000

Home Brew.

We have got a home brew set from the shop just down the road, and are trying this out (we will keep you posted…), it makes the house smell like a brewery!

Queens Diamond Jubilee

I am trying to get the Americans a bit excited about the Jubilee, but oddly they don’t seem as interested by this as they were by the royal wedding!

Sarah’s work visa.

Sarah has finally got a work visa through, and now has a Social Security Number, and so is finally in a position to get a job. Hopefully all the networking she has been doing will rapidly pay off and she will find a good job.

Heat and humidity.

The heat and humidity are really jacking up, now as soon as you do anything physical you break a real sweat.

Assistance Required: Design guidance on Cryogenic system

To Mark/Jim and others who are interested

At the moment I am working on a design check of a liquid nitrogen cryogenic system.

The exact questions / issues that I am looking into are:

1. Standards / Regulations / design guidance as to the materials to be used for the liquid nitrogen line and the cyrovent line.

2. Standards/Regulations for frequency for Cryovent cut ins on Liquid Nitrogen Line

3. Standards / regulations of venting liquid nitrogen boiloff

I have looked at ASHRAE refrigeration guide Chap 47, but this does not seem to have the answers I need. the others around me aren’t sure where else to go.

THe Sub-contractor who is installing the system seems sure of themselves and is stating the original design was inadequate and it should be installed the way they are doing it (which oddly costs more).

(Definition of Cryovent – a port that allows the boiled off nitrogen to escape.)

May 16 Commissioning and Transfer of focus to USAMRIID

In brief

I have been finishing off various items within the handover of the Steam Sterilization Plant, and starting to get more stuck into more aspects of the main USAMRIID project

Key Interesting points

Snagging and deficiencies lists within SSP.

We have generated a comprehensive snagging list for the SSP, and the discussion about what is exactly stated in the specification has ensued. It is interesting that despite the fact that no 5% retention is held no one is concerned that the contractor will not make good his mistakes, this is due to the power that the federal government (Us) has to command them to work, and the fact that it is essential for the contractor to stay onside with the Corp of Engineers for continuing work.

Testing of PALL filters.

In order to filter the high pressure steam the other gaseous waste from the SSP, HEPA filters are used to clean the air. These operate at high pressure and high flow rates. The testing of these filters has taken 3 weeks, due to the complex nature of the filter skids, and the fact that the method of testing has had to be changed several times to find a test that will allow the filters to pass. We have had to ensure ourselves then reassure the client that the “easier to pass” tests do give the same level of assurance and will be repeatable within their operation and maintenance schedule.

Investigating “Leak in system”

Within the SSP all non expected liquid waste is drained down to the basement, from where it is pneumatically lifted to the storage tanks on the top floor, ready for processing with the other effluent. The receiver/ejectors in the basement have been firing more than would be expected, and so I have been researching to try and find a plausible source of the water, as we were concerned that it might be a symptom a larger problem. Having isolated an onsite Auto-Clave this appears to have prevented the consistent leak, and so this more easily fixed than we had feared.

Design Alteration to the SSP

As mentioned in previous Blogs a design fault has been recognized, and is in the process of being corrected. In the meantime most of the other work has been finished to the original timeline, and so is nearing completion. A difficulty has arisen in so far as the contractor wants to know whether they are to hand over the building now as originally agreed in the contract and the original design, or continue maintenance of the facility for a few months until the design change is finalized and complete, and so they can hand over a fully working facility. Clearly either of these two options causes costs, and have their own advantages and disadvantages. Trying to extract these costs from the design contractor is apparently unlikely to succeed due to the contract style employed by the Corp of Engineers and federal Government.

USAMRIID

Duct Testing

Conducting and signing off the pressure tests of the installed air ducts – ensuring that they are adequately air tight,

Coating Application

Due to the higher heat and humidity than would be seasonably be expected it is causing some concern for the application of coatings. These are quite sensitive to atmospheric conditions, and it has been agreed in the contract that within selected high containment (high value) areas they will be monitored, this has worked for these selected areas, however the non monitored areas are noticeably less controlled and a lower quality of finish is achieved.

It has been decided that the cheapest and easiest way would be for the Corp to monitor all the others areas with HOBO data loggers, and then provide this information to the contractors. This is another example of the Corp assisting the Contractor more than might be usual, and so at least from our side the partnership relationship seems to be going well!

Partnering

Having observed different members of the contractor and Corp interact it has become clear that the “partnering” spirit is mostly more visible in the Corp (probably due to the more relaxed approach to budgets), and also very highly personality dependant. It appears that the Latham report has not been fully read and digested by the older members of the contractors. Partnering with someone who does not want to reciprocate seems in some ways to be worse than both being adversarial, and both playing the same game.

Lack of Shop Drawings

In some of the areas of the USAMRIID project the Corp have allowed the contractor some flexibility of the detailing, in order to allow them to find the most cost effective solution at the time of construction. This is now causing some difficulties as the contractor is now unable or unwilling to provide shop drawings, and so signing them off as an acceptable method is difficult, as are inspections. This is leading to some disputes where the contractor is stating that our lack of movement on the inspections is delaying them, but we are in turn waiting for the shop drawings in order to do the inspections. They seem to be obstinately not listening!

Valve Access

Due to the high density of services within the USAMRIID there are many places where it is difficult to get to the commissioning and isolation valves of the mechanical system because other systems have since been placed in the way. This is clearly unacceptable and will also be very costly to correct, due to the number of places where it has occurred. This does seem to be an elementary error, that should really have been stopped before it got this far, however the number of services will make any solution difficult to implement. I am considering suggesting the use of highly trained monkeys for the O&M crew, as they will be smaller and also able to climb on the ducts.

What have I learnt?

Valve access

As early as possible in the design process the maintenance of the plant must be considered, otherwise it is doomed to fail. Within this project it would probably have led to even more services floors, and a higher price-tag so would have been inevitable. A full 3D services plan would have helped for the visualization of services clashes.

Testing and Commissioning

Do not underestimate the time and budget required for the testing and commissioning, especially on complex projects. Problems will be found, this is the point of the process. Ensure there is a plan in place for making larger and time consuming alterations.

Coating Application

The sheer act of monitoring will increase the level of workmanship, as long as it is done across the board and against clear and relevant criteria.

Partnering

Can be effective, yet the stick is also still required at times. Try to imbue a partnering attitude from as early on as possible, and work hard to maintain this.

It’s not essential, but i am intrigued…

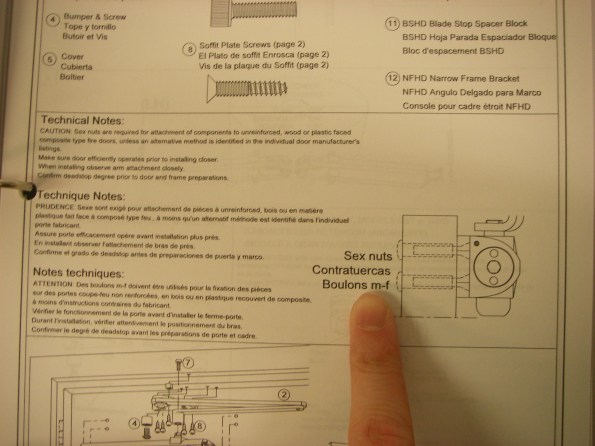

I found an interesting term within some of the Fire systems literature that i have been reading – see photo.

I tried “Googling” it to find out what it was, but had no joy, but had no success…

What do you think?! I had to ask everyone round the office is they knew what one was.

I think Chris W might be the best person to advise.

Having written my blog in Microsoft word, it wasn’t pasting into the browser nicely so I have uploaded the document instead, hope this is readable to those who want to read it!

Not many photos as yet, the project itself is not very photogenic, but once i get some good shots i will upload them.

Ben