Archive

Heat Pumps or Hydrogen?

Some are touting the Hydrogen Economy as the way forwards, while others claim Heat Pumps are the future. Thus far at Siemens, I have only seen evidence to support the former. Anyone seen anything from industry to lend weight to the argument either way?

Recent Sunday Times Article on a Hydrogen trial for clean energy.

Emily Gosden, Energy Editor | 432 words.

Hundreds of homes in Scotland will be the first in the world to have their heating and cooking needs met by pure hydrogen after a £28 million trial won funding from the energy regulator. About 300 properties in the Levenmouth area of Fife will have hydrogen-burning boilers and cookers installed without charge and will be connected to a new pipeline network supplying them with 100 per cent “green” hydrogen. The gas will be produced through electrolysis, which will use electricity from a wind turbine to split water into hydrogen and oxygen. The first homes are expected to be connected in 2022, with the trial initially running for four and a half years. It is being run by SGN, the gas network company, which has been awarded £18 million funding from Ofgem and £7 million from the Scottish government. Decarbonising Britain’s homes presents a significant challenge, with about 80 per cent of homes using natural gas boilers that emit carbon dioxide, which causes global warming. Hydrogen has been touted as a potential solution because it burns cleanly. Although boilers and cookers would need to be replaced, hydrogen boilers could be used in conjunction with existing central heating systems. Proponents say that this would be less disruptive than switching to all-electric heating systems, such as heat pumps. It also could enable the continued use of existing gas networks, which would be beneficial to companies such as SGN, which distributes gas to 5.9 million homes and businesses in Scotland and the south of England. Angus McIntosh, 42, director of energy futures for SGN, said that the trial was an “exciting opportunity to revolutionise the way millions of people heat their homes”. He said that the high costs for the demonstration project included the fact that the boilers and cookers were “essentially having to be handmade for the purposes”, but added that significant cost reduction was expected if hydrogen was adopted at an industrial scale. The hydrogen will be produced using an existing seven-megawatt wind turbine in Levenmouth and a storage facility will be constructed to hold enough hydrogen to supply the three hundred homes for five days with no wind generation. As a fallback, the electrolysis could be run using power from the national grid. Mr McIntosh said that the trial would be voluntary and would be “as safe or safer” as using natural gas. The hydrogen will have the same odour as natural gas and will burn with a coloured flame in the cooker. In the event of a leak, a safety device should detect it and cut off the hydrogen to prevent it “ever being able to accumulate to an explosive level”.

Contract Dits from Siemens Gas Turbine Servicing

Background

Siemens offer Servicing Contracts for their Engines known as Long Term Plans (LTP), these broadly fit under two categories:

1. Preventative – Siemens will send Engineers to site to preemptively service the Engine in order to guarantee 100% running time (aside from during periods of planned servicing). The engineer on site, in consultation with experts back in Lincoln, will balance the cost of servicing/replacing components against the likelihood of failure during in the next running period (24000-36000 hours). “Over servicing” engines gives a higher degree of confidence that engines meet 100% running time, but also increases cost (components, time on site, Engineer expenses – hotel etc). “Under servicing” engines gives a lower degree of certainty. Civils if you’re still reading – think John Moran screaming RISK!

2. Corrective – Siemens will send Engineers to site only when an Engine Fault Occurs. Siemens has Engineers based all over the world to minimise travel time.

Siemens offer a remote Engine monitoring service that feeds engine telemetry data to Lincoln, from here Siemens can analyse the data to give advice to the customer in the event of a small fault without physically needing to be at site. Additionally, all this data allows Siemens to better predict component failure – a bonus for the preventative plans.

Generally speaking:

1. Smaller companies opt for LTPs to mitigate risk.

2. Larger companies such as Oil Majors (Total, Shell etc) prefer to remain as ad hoc customers for servicing. Why you may ask….. Because they are so valuable in terms of servicing revenue and potential new Engine revenue, that Siemens will drop more or less everything to get engineers out to site to fix the problem. If Siemens didn’t adopt this attitude, the likes of the Oil Majors would go elsewhere for New Engines (Solar, GE) and Servicing (Centrax), to name but a few competitors.

Dit from Last Week – Qatar Petroleum (QP)

QP don’t have an LTP with Siemens, however, Engine ceases to run Friday 3pm UK time with QP demanding an Engineer on site (offshore rig) within 24 hours. Cue much flapping, however an Engineer was on site within the time frame and reaching back to experts in Lincoln. Would Siemens extend this level of service to a smaller company at a more difficult location? Absolutely not, they would be told to wait in line.

Covid-19 Frictions

1. Mandated 2 week quarantines either side of international travel in some countries.

2. Some customers won’t allow engineers on site to conduct servicing at this point in time.

So What

Siemens have a growing back log of customers requiring servicing, however are unable to deliver it due to the frictions mentioned above. In the coming months there will be a time when Siemens will predict the likely failure of one of their Engines through remote Engine monitoring, but be powerless to send an engineer out to site to prevent it. In the event of a failed engine on a preventative plan, and in the eyes of the customer, Siemens have failed to meet the servicing contractual arrangements.

Bottom Line

Siemens will be looking to use Covid-19 as a Force majeure to free itself from the obligations in some of its Servicing contracts. I’ll be reaching for the popcorn when this happens.

Green Hydrogen

Clean, reliable and secure energy supply is a key requirement for the further development of the European economy. At the same time, the Paris Agreement and its aim to limit the global warming to well below 2°C call for a quick and significant reduction of CO2 emissions, including the energy sector. In the energy sector this can only be achieved by a significant increase of the share of renewable energy sources (RES). As the most abundant RES, wind and solar, are intermittent by nature, there is a need for energy storage technologies, to provide back-up power when wind and solar output are low and more generally for load levelling and grid stabilisation.

Chemical storage appears to be the most promising long-term energy storage technology. Among chemical storage technologies, hydrogen is expected to dominate as it can be produced by electrolysis of water using excess energy from RES, easily compressed and stored, and finally re-electrified using gas turbines.

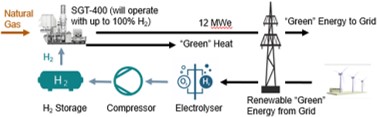

Siemens vision for energy

e-Hydrogen is the generation of Hydrogen through electrolysis of water.

The Role of the Gas Turbine

Siemens are currently modifying existing Small Gas Turbine Combustor technology to burn both Natural Gas and Hydrogen for fuel. These Hydrogen and Natural Gas Co-firing Gas Turbines will be able to run on any ratio mixture of Hydrogen and Natural gas, with the desired proportion being solely hydrogen. Natural Gas stores ideally would be used for redundancy or emergency purposes.

Emissions & Closed Cycle

(Civils if you’ve made it this far, cheers)

The combustion of Hydrogen in pure oxygen yields water as the only waste product, as follows:

This means theoretically the only exhaust products out of the Gas Turbine will be steam, therefore the intention is to turn the engine into what is known as a closed cycle. Whereby the exhaust steam is condensed to water, and fed back into storage for subsequent electrolysis into hydrogen and oxygen.

The reality is that combustion of Hydrogen in Air will additionally yield oxides of nitrogen – bad. This will drive development of more robust catalytic converters to strip oxides of Nitrogen out of the exhaust.

Further Reading