Archive

The blind leading the blind.

I have now started my design attachment in the USACE’s Baltimore District Headquarters and am currently working on two projects. One of which is a ‘server room’ cooling survey at Fort McNair in Washington DC, which this blog will focus on outlining.

I have realised my utility, I am cheap, and so have used this to secure some responsibility early. The project budget is $50,000 and, in the mechanical section, the average engineer’s time is billed at $135 per hour. The basic sum on this gives an engineer 370 hours, but add in project manager time, vehicles and other overheads and it can soon be eroded. This is something I will research into for a further blog but the upshot is that this is now my project, and a handsome little mess it looks like to. The scope of the work currently is to write a report on the cooling within a number of server and communication rooms within the Military District of Washington (MDW) office buildings. There are 15 different rooms spread across 8 buildings, built circa 1900, all with vastly different loads and in different conditions.

After meeting with the USACE project manager, the client and the HVAC engineer for the buildings, Don Ruhl (my partner from the mechanical section) and I toured a number of the rooms. As we travelled around it became apparent that not only did the client not know what they wanted; they also didn’t know what they had in the rooms. The photos give an idea of a couple of the rooms and the varying conditions.

Don inspecting the many unsealed penetrations in a small converted basement broom closet. This room had about 12U of switches and had a retrofitted ductless cooling system. It also had a condensate drain to a sump, thus allowing the condensate to re-evaporate and continually cycle through the cooling system.

Another basement room with abandoned hardwiring to the Pentagon. About 45U of high grade servers in here. The pipe on the floor is for chilled water with heavily damaged insulation allowing condensate to form on it in the summer.

Server rooms are ideally internal within a building in order to avoid solar heat gains and also because servers don’t need a window to stare forlornly out of. They are usually sealed from infiltration; tidy, to control airflow and have some form of HVAC. The current standard for low and medium density data centres and server rooms is to use a hot aisle, cold aisle system as illustrated below. Cold air is fed from low down in the ‘cold aisle’, either through the floor or by retrofitted ducts; the server blade draws it in through the front and rejects warm air through the rear into the ‘hot aisle’. This rises and is collected by the return air system. As the photos above indicate this was not the case.

So what. Well given the conditions in many of the rooms, even doing a complete survey would be incredibly costly on time. After this initial assessment we need to engage in some expectation management in what we will be able to provide and re-write the scope of our work, which is currently pretty open ended. I see this largely as focusing effort on the more important rooms in terms of upgrades and identifying the risks of each room to the client so that they can make an informed decision.

In an age of BIM, I have been told that the best we can get is a floor plan for some of the buildings so it appears that even a set of out of date as built drawings are a wish too far. Due to this if construction work is ever completed on this then the contract will almost certainly have to be a design and build as the potential for change orders on a traditional contract would be immense!

Finally, a little leadership challenge.

I mentioned earlier that I had been given the lead on this project but I am working with another engineer. Don has worked for USACE design section for at least 30 years and is probably the most intelligent person I have met out here. He has no aspirations of leadership and is very happy to let me control things; however his ability to take a tangent and dive too far into the details too early are something to behold. Certainly a different management challenge from both soldiers and contractors!

Hospital Pass

Part of the role of USACE, as the client’s representative, is to conduct design reviews for design-bid-build contracts (read traditional contracts). These are done at 35, 65 and 95% with comments provided back to the project manager and design team, be it in house or a consultant, through an online system (Dr Checks). The designs are reviewed by us at construction division as well as the design division and are passed out to the clients and facilities managers, probably amongst others.

A couple of weeks ago, due to staff being on leave, I was given one of these to look at the pumps, seemingly alone. Having no idea what to do I browsed the drawings to work out what the issues might be. The project is a new 750,000 U.S. gallon water tower for domestic water and as a fire supply so my pavlovian response was Bernoullis!

After checking the answer it seemed about right although there were no accompanying design calculations to the contract and drawings so I chalked up my first comment. The rest of the checking passed with less excitement. There were a few clauses that had been missed from the contract, some ill thought out processes and demolition elements missing from the drawings. It seems a common theme though that construction division give the most comments, usually about build ability and, as discussed in the past, what is actually existing at the site.

So what have I learnt:

Hopefully I’ve done Bernoulli’s right; simplify the problem and sketches work.

Designers, it appears, live in a magic construction dreamland and it is always the same build ability issues that are picked up. By using traditional contracts USACE does assume a lot off risk and pays handsomely for the privilege if elements aren’t caught by the construction team prior to tendering. Having recently moved into dreamland, albeit part time at present, the fine detail is easy to forget.

And as ever, time spent on recce…

When concrete goes bad…

The Wastewater Treatment Plant project I am working on has quite a lot of concrete tanks. Amongst these is the ‘Plant Water Vault (PWV)’ which for the first month I assumed was just another tank, but couldn’t place it in the treatment process. Turns out its not a tank, but a pump lift station. Confusion rectified it still looks like a tank and part of my role has been doing rebar inspections. In the grand scheme of things they are probably pretty simple as it is a box with a few, but not that many, penetrations.

Below shows the form work and rebar for the ceiling.

And the ceiling is where the problem lies; it’s not meeting the design strength. The pours for the base and walls have been comfortably meeting the 4500psi strength in 28 days as one might expect. However, at 28 days the contractor had to do some rounding up of the percentage strength up in order to meet the 85% threshold for removing the formwork. Now at the 56 day point the last two breaks have come in at 4400 and 4320 psi.

So what… The short and simple answer is strip it out and try again it as it doesn’t meet the spec. At the 28 day point when we were looking down the barrel of this as a possibility that is exactly what my boss said cueing the squirming; not least from the concrete supplier who I believe will be footing any bill. However in reality all parties are aware that a compromise will probably be reached. The options on the table on Thursday were:

- Feasibility of replacing slab. This really is the last resort for all:

- Quality: It will definitely meet the quality.

- Cost: Nil for the Government; expensive for the contractor and concrete supplier.

- Time: 2 weeks for breaking, 2 for forming, fixing and pouring, 4 for curing. The PWV isn’t on the critical path but the steel fixers have weeks of work in front of them and winter is coming fast.

- Destructive testing of cores. Will assess the difference between the cylinders and the real condition; they are as likely to be worse as better.

- Quality: Difficult to find a gap in all the rebar to core.

- Cost: Cheap for contractor

- Time: Results back in a week before next decision is made.

- Structural Modifications. Adding more steel to bring to strength. This requires a design analysis of which element of the concrete requires to be 4500psi.

- Quality: Unknown as we don’t know where steel will have to be placed. The PWV is hardly a work of art already so a bit of steel won’t hurt.

- Cost: Less expensive than replacing the slab.

- Time: Overall it would be concurrent activity so wouldn’t add to the programme.

- Analyse the slab to check the required strength. Apparently concrete is specified in 500psi increments so there is a chance that it is strong enough already. USACE could ask our design consultants to do it but that wold cost us money so we won’t. Instead the contractor can do it independently and our consultant can check it.

- Quality: We wouldn’t get what we asked for, but we would get what we need if the calcs showed that the concrete was strong enough.

- Cost: $500 – $1000 for a Professional Engineer for a day.

- Time: A week or two and if all is good then no knock on to the programme time.

So we are going down the analysis option, which would be required for the structural modifications anyway. From there on we will see what happens.

The PMV in the background. The actual tanks are currently being poured and will keep the steel fixers busy until the end of November.

And finally…

This is now the second car crash I have seen in 6 months of being out here. The woman in the blue car turned in to get gas, but tried to go through another car to get there. I had been planning on using that pump but it was blocked when I had turned up. Fortunately no one was hurt but all of the blue car’s airbags deployed and her groceries met her in the front of the car.

PS. I don’t know what mix the concrete is Damo so don’t ask.

Building Services and Bio-engineering.

Hopefully my absence from the blogosphere has not been too keenly felt however whilst away on Ex Bugaboo Tiger I have been continuing to learn. Sadly we weren’t able to stay at the comfortable hut in the Bugaboo Provincial Park but I stopped in for the a brew on the way past and I managed to have a look around the services. We also had a broken leg on the trip which required the combined talents of a doctor and engineer to bring about a recovery.

Building services.

The Conrad Kain Memorial Hut is remote. It is an hour’s drive up an unpaved surface to a car park and then a 3 hour steep walk from there. Apologies for the lack of detail however I restrained myself in my question asking of the Guardian:

Water – It is just below a glacier, so water supply is not a problem. The water is filtered though being glacial the risk is low, the highest risk is from things like Weil’s disease as there is plenty of rodent life in the park.

Waste – The rules of the park are, if you ‘pack it in, pack it out’. This is well advertised and people we met were generally responsible.

Human Waste – Fortunately one didn’t have to pack out your human waste from the hut, or even our higher campsite. Pit toilets dropping into plastic barrels (similar to those used for industrial chemicals or Himalayan expeditions) were positioned outside. The Guardian’s least appealing responsibility was to change and seal each of these barrels as they filled. In order to maintain the delicate glacial environment visitors are encouraged to use wag bags if they are caught short away from the hut/campsite, they can then put their bag into the pit toilets. All of these are stored up over the summer and transported down at the end of the season by helicopter.

Cooking – Gas in large portable cylinders is used for most of the cooking; these are resupplied by the helicopter also. There is also an electric 4 hob cooker.

Electricity – Electricity is used for the radiant heaters, lighting (using energy efficient lamps) and all small power requirements: including the guardian’s fridge. The electricity is supplied by a small hydro station maintained by the guardian. It provides up to 10kW of power when the water is flowing well, as you can see from the picture below sometimes it runs too well!

The pool feeding the micro hydro station. The dam obviously requiring some maintenance due to the weather.

I forgot to ask whether there was any electrical storage but it didn’t appear there was, that said the two hot water tanks act as a residual energy source for the heating at least.

Food – Like waste out visitors ‘pack in’ their food. The poocopter brings dried food up for the guardians on the uplift at the season change, which they compliment with fresh on their weekly commute.

So what:

To me the set up was interesting for its own sake but it also has some parallels with operational infrastructure. The human waste system seemed particularly effective as it had both a low logistical burden but also preserved the local environment. As we moved to exclusively using wag bags in some of the FOBs in AFG this barrel system would have been cheaper, logistically simpler and actually more comfortable.

Bio-engineering.

On the descent from our last route in the Park my climbing partner broke his leg, which presented a bit of an inconvenience. Fortunately with the help of a doctor and some zinc oxide tape we managed to affect a solution that was good enough for him to walk back to camp. Fortunately, for this circumstance, WO2 Whale’s right leg is prosthetic. The issue was that the grub screws holding the foot to the titanium leg had worked loose. This was despite them being glued into place. Making a stirrup of zinc oxide under the foot we then secured it in place by wrapping around the leg. More used to tubi-grips Doctor, Maj Martin-Bates made a good job of the taping.

As WO2 Whale has never had this happen before I assume the cause of the loosening of the joint was us wading through waist deep snow the day before. Usually your leg is in compression but pulling it out of a snowy hole causes some tension thus aggravating the joint and the grub screws more. The long term solution was a 4mm allen key in his tent, which perhaps should have been in is pack instead!

Finally to prove I wasn’t ‘having fun’ here is a picture of us setting up camp.

Fame!

To follow on from Brad’s blog the internal media department have flexed their literary muscles to create this on our time with the DA and about the exchange programme. It is now hidden in the vastness of the US Army website:

Brad and I have crates available for collection at our respective houses, just come around and collect.

Offer closes 24 December 2015, all unused crates will be disposed of semi responsibly.

Defence Reporter

I am not sure of how others come by their Thesis ideas, however I certainly didn’t find one drop in my lap from working on site and so had to go looking. I would encourage those in Phase 1 to start thinking about it before leaving Chatham. A resource I have found for contemporary research from DSTL is Defence Reporter:

https://www.gov.uk/government/publications/defence-reporter-mod-research-reports-on-athena

The periodical only gives the abstract and you have to apply for the reports which appear to get posted. Mark said he has used it before but the system appears to have been formalised more since. Some of the reports may be worth applying for, most certainly aren’t. The above link gives the back copies and you can subscribe, the issues are irregular but at worst it is four extra emails a year to delete from your junk mail!

How big is the bus?

I am not sure whether the client usually gets to see the value of each of the subcontracts but it appears that we do. So for my FtIG project I can see that ‘the bus’ is costing us approximately $110,000 or 27.5% of the contract value. From what I have seen so far this pays for two slippery salesmen and an OAP in a portacabin who is going to run the site. Although we are supposed to get the information it has been accidentally added into the emergency contact submittal, which was clearly part of a larger spreadsheet, but you can get the idea

Flippant as I may be this clearly also considers the various overheads that have been incurred not least the cost of tendering for the project and the 4 months of paperwork that has been done prior to getting out onto site. This in cash-flow terms is a significant burden for a small company. Also in there will be the risk for things not going well, something that is quite likely in replacing an old system. I am not sure whether Greg or Steve have any thoughts on the general mark up on something like this.

As far as progress goes, yesterday I met the aforementioned OAP who is to be the superintendent, Quality Control Manager and Site Safety and Health Officer (SSHO) and some materials were delivered. I took the opportunity to get some shots of the interior:

Writing a schedule that helps you get paid.

Safe in the knowledge that everyone will be too busy fawning after Mike’s baby…

I just reviewed the FtIG boiler project schedule, again. Now, on version 4, the contractor has lowered my expectations sufficiently that I am now focused only on the money. Their timings for installing pipe work are unrealistically short and everything appears to be on the critical path. These, though annoying, are their problem as the contractor is responsible to ensure there is no gap in service for hot water, heating or cooling within certain seasons.

So resigned to failure on the time side I have turned to look at the money. USACE pay for definable elements, rather than the alternative of paying for percentage complete on the whole job. From the pay reviews that I have conducted for the Waste Water Treatment Plant this appears to be a better form of holding the contractor to account for finishing up individual elements. By paying 98% of an element that isn’t quite finished it leaves a virtual snagging list in dollars. These are more likely to be completed by the next pay period rather than being forgotten until the end of the project, when especially if there is a staff turnover, they get swept under the rug. We will pay for stored materials but, it has to be a significant element, the contractor has to show ownership and we prefer if it at least in place. For this project the boilers and water heaters may come into this but certainly nothing else. Again, for the waste water treatment plant we have paid for stored materials for a $60k generator and a $130k pump set so that really sets the magnitude. I’d be interested to hear what everybody else’s clients’ are happy to pay for on that?

So what’s my issue with the FtIG values? I have two:

To me definable elements are like a product breakdown structure (PBS) and when it comes to pay time I want to be able to go to the element, look at it, tick a box and pay the contractor. This is not me being an idle box ticker rather ensuring that each element is well defined, and I assume this will help them with their sub-contractors. The FtIG programme has not been built from a PBS so I can foresee the arguments coming at pay time. The lesson from this is do a detailed PBS, even for a simple job, because it has ongoing utility beyond just being the start of a programme.

I remember Steve Payne hammering the PBS into us in phase 1 but this experience and if I had any doubt then it has gone. The issue of everything being definable is important too in order to communicate the plan to different people. I am, reasonably, sure that the sub contractor knows how to do this work, however they have not managed to communicate this effectively to the contractor who, in turn, has not managed to communicate it to me. I am sure this is a lot worse in the larger projects with more people involved.

Front loading. The contractor admitted before that the project was front loaded, we all laughed and I told him that we wouldn’t accept front loading. They went away and when version 2 came back it was worse rather than better. I am aware that the contractor requires cash flow. Working for the Federal Government cash flow is not a problem, however I need to ensure that if the contractor goes bankrupt that I still have the money left in the project budget to put the remainder of the contract back out for tender. The solution to us meeting a better agreement actually came from the contractor letting me loose on his values. I can’t pay them any less than the contract value, all I am doing is moving around what the money is tied to. I am sure there will still be more iterations required before we come to final agreement but it’s a start.

In terms of submittals, over here the Navy ask for a ‘schedule of values’ as well as a schedule (programme), but USACE ask for both as part of the same submittal: the schedule. I’d be interested to hear how others have seen this being asked for by clients? For checking on the client side I think breaking them out would be best.

Apologies for the lack of pictures, I have avoided putting the programme in as it is little changed from a couple of blogs ago, and looks pretty difficult to see on a computer screen.

Two things are infinite.

Einstein said: ‘Two things are infinite: the universe and human stupidity; and I’m not sure about the universe.’ This is a theory I have long signed up to and today I can add another piece of empirical evidence to the data set.

One of the Access Control Points (ACP, or gate in English) to the camp at Harrisburg is being upgraded because of the perceived threat to the site from terrorists. On the security front I could wax lyrical about the fact there is a small airfield adjacent to the camp, that it has the lowest grade of fence in the U.S. military catalogue, or that I could squeeze through a gate on the Northern side of the perimeter fence. But greater minds than I have decreed that the weakness is at the main gate so that is what is being upgraded.

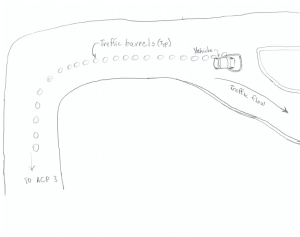

As part of the upgrade the road layout is being adjusted with an alien feature to American roads: a roundabout. I have seen less than 10 roundabouts (or traffic circles to use the vernacular) since being out here and each appears to have its own rules. People also appear to be petrified of them, probably because they are so rare and non-uniform. Because the construction is taking place on an operational road building the roundabout has been phased. It also means that everyone has driven past it for the last two months; which is probably enough of a lead up to know what might happen one day.

On Monday we signed of the transition to the next phase of construction and as a result the traffic route was changed in the afternoon for the next phase. Traffic now enters the camp in a different lane weaves about a bit and then hits the roundabout. To be more precise, only half the roundabout and the idea is obviously that you go ‘round’. So without looking at the artist’s impression below you can probably guess what happened this morning.

A driver had managed to mount her car on the triangular lane splitter at the entrance to the roundabout. When in full operation this apparently shouldn’t be catastrophic as the kerb is ‘mountable’ and the level inside the triangle will be brought to the top of the kerb with concrete. At the moment, half constructed, the inside of the triangle is at road grade level, about 8 inches short of the final level. As she tried to reverse out of trouble she broke off her bumper and has apparently damaged her front axle assembly and because of that the car is ‘totalled’.

So what..

Well it lead me to thinking what could we have done about it. Filling the hole in would have reduced the damage sustained to a vehicle but would have caused rework or having to order in concrete. In the end more cones were placed in the triangle to ‘give more reflection’ as the driver said she hadn’t seen the kerb. My opinion is that more flashing lights and reflective bollards aren’t really going to help if someone is looking at their phone rather than the road and that human nature is always going to cause the odd accident. The best prevention of a future accident is the fact that everyone driving in that morning will have seen the car stranded and might be more vigilant: for a few days.

Fortunately no one was hurt in the accident, something I should have mentioned earlier. This was because, by chance, no work was being done in the area. Maybe, as a safety measure in the future though, a soak time of a couple of days after a road layout change might be a sensible safety precaution in an area where commuters operate on autopilot in the mornings.

The below pictures show the phases of construction for the roundabout. The accident happened in the phase 2 layout moving from the top of the image.

Finally, to follow on from Damo’s post about cyclist safety:

It doesn’t sound like it will happen any time soon, however it could have huge implications for construction within whatever zone it was implemented. Damo, has the cycle safety scheme on your site been well received?

Levee Inspections

To attempt to take up the mantle from Howard of saving Pennsylvania from catastrophic flooding this week I have been out conducting inspections of elements of the levee network. Every year Baltimore District inspect half of the levees in their AO, which broadly covers Pennsylvania and a section of upstate New York and control flow into the precious Chesapeake.

Sadly my image of Hollywood style concrete channels where we could put the hire car to the test were dashed and replaced by oversized earth berms. I imagine this is the slow time equivalent version of the inspections carried out in six weeks by RE JNCOs in the UK last spring, except completed by two qualified Professional Civil engineers and a couple of hangers on like me.

Below shows a typical levee and our main tasks were to look out for ‘critter’ holes and the wrong type of vegetation. A common occurrence is for groundhogs to burrow completely through the levee, both allowing flow but also destabilising the remainder of the levee. Vegetation is important to promote soil stability but has to be able to bend to the flow to avoid creating an obstruction, or a place for obstructions to settle. Within the main straight channel to the bridge in the distance a meandering path has been engineered for the normal flow condition slowing the flow down, whilst allowing it to drain quickly in a flood condition.

To control flow through the levee from drains gated inlets are used and flap gates prevent back flow from the river up the pipes. These all required checking and had been greased to the standard a farmer would have been proud of.

The systems we inspected were built from the 1940s onwards and were simple and robust in their design using, as one would hope, gravity where possible. There were a couple of pump stations with standby generators where gravity had to be overcome. As the drawing shows below a lot of effort is taken to remove the debris and sediment from the flood water to protect the pump and prevent it clogging the pipe work (or pressure conduit to use the vernacular).

Rip-rap is 6” diameter rough stone.

As far as analysis goes the question in my head this week has been how does it all integrate? My conclusion is that it doesn’t. Responsibility for each levee has been pushed down to the lowest level of government, the Township, and so there doesn’t appear to be an appetite for integration from one to the next. That said, as the map below shows, there is quite a lot of space between townships out here and so maybe that doesn’t matter.

I imagine further down stream towards the coast where the population density is higher and all the water converges this would be more of a problem. For now I am going to shelve these thoughts and pick them up again when I get to phase 3, where I can speak to the hydro engineers in their natural environment.

Finally, for the civils who were whinging about making a cofferdam, this is how you do it ‘redneck style!’

And apparently this is a salad…